+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

In large-scale infrastructure projects, from landfills to reservoirs, geomembranes are essential for containment and protection. A critical component of installing geomembranes is welding, a process that ensures the geomembrane sheets bond seamlessly, providing a reliable barrier against leaks and contamination. This article explores the concept of a “welder geomembrane,” detailing the purpose of geomembrane welding, its applications, and the differences between geomembrane materials like HDPE. Read on to understand how geomembrane welding plays a pivotal role in achieving strong, secure seals in construction and environmental projects.

What is geomembrane welding?

Geomembrane welding is a process used to join sheets of geomembrane, creating a continuous, leak-proof barrier. This welding is typically performed with specialized equipment, often called “welder geomembrane” tools, which apply heat and pressure to bond the material. There are several methods, including extrusion welding, fusion welding, and hot wedge welding. Fusion welding, for example, heats the two sheets until they melt and fuse together. Geomembrane welding is crucial in ensuring that the barrier remains intact and performs effectively for years, preventing leaks and protecting the environment.

What is the difference between geomembrane and HDPE?

Geomembrane is a general term for any impermeable membrane used to contain fluids or prevent contamination, while HDPE (High-Density Polyethylene) is a specific type of geomembrane material. HDPE geomembrane: harder, more rigid, suitable for projects requiring high strength and durability, stands out due to its exceptional strength, chemical resistance, and durability, making it ideal for challenging applications like landfills and chemical containment. Other types of geomembranes include PVC, LLDPE, and EPDM. HDPE geomembranes also offer high resistance to UV exposure and punctures, distinguishing them from other materials often used in less demanding environments.

What is fusion welding of geomembranes?

Fusion welding is a specific welding technique used in geomembrane installations. In this method, heat is applied to the surface of two overlapping geomembrane sheets until they reach their melting points. The two sheets are then pressed together to form a strong, continuous bond as the material cools and solidifies. Fusion welding creates a high-strength, reliable seal and is widely used in projects where durability and impermeability are crucial. This technique is particularly effective with HDPE geomembranes, which respond well to fusion welding due to their thermoplastic properties.

What is geomembrane used for?

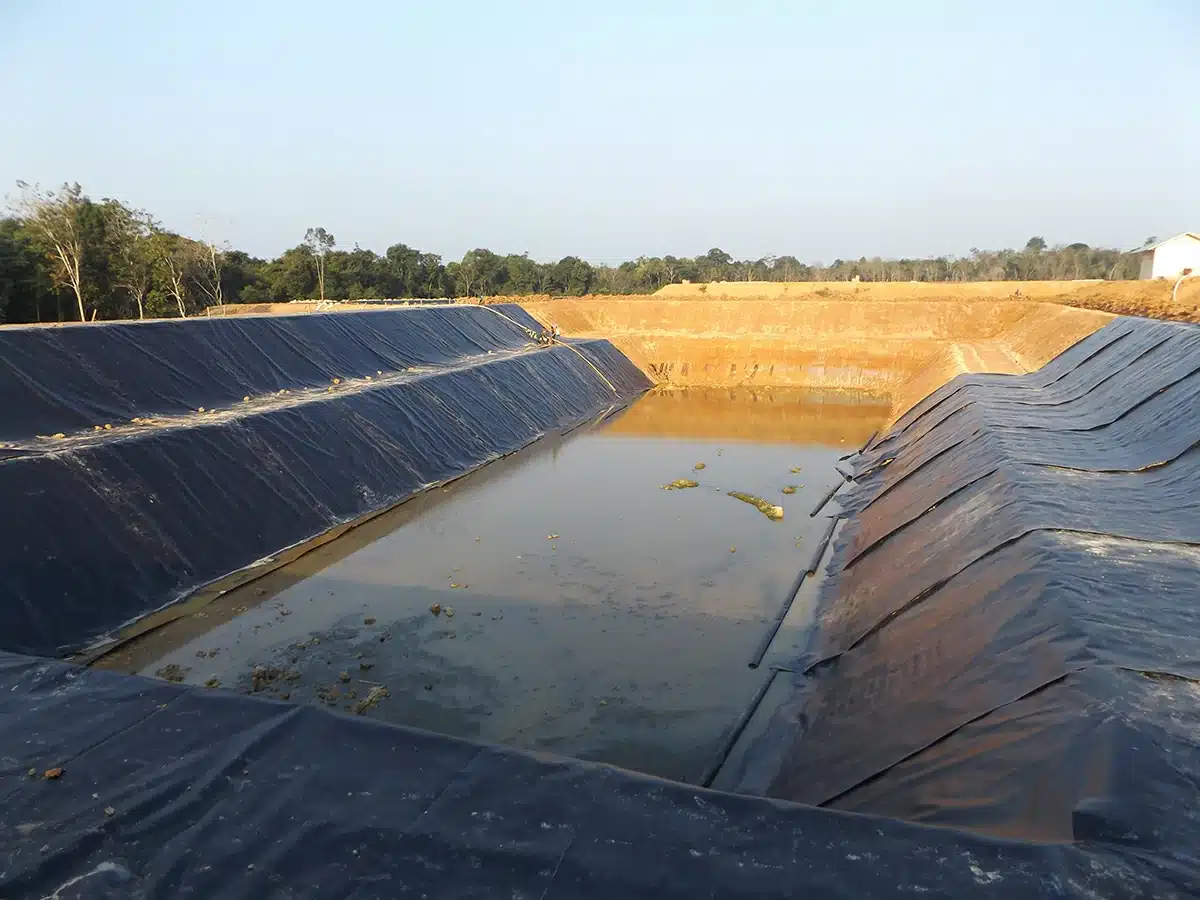

Geomembrane is used in various containment and barrier applications across multiple industries to control fluid (liquid or gas) migration in a human-made project, structure, or system. It is commonly found in landfills, where it serves as a liner to prevent waste leakage into the soil and groundwater. Geomembranes are also used in water reservoirs, ponds, canals, and mining operations to contain water and control seepage. Additionally, geomembrane linings are applied in industrial facilities to contain chemicals, reducing environmental risks. Overall, geomembranes provide a durable, impermeable barrier essential for protecting the environment and ensuring infrastructure stability.

Welder geomembrane technology is essential for achieving secure, impermeable barriers in diverse containment applications. From landfill liners to water reservoirs, geomembrane welding ensures strong, leak-proof bonds that enhance environmental protection and infrastructure resilience. Understanding the types of geomembrane materials, like HDPE, and welding techniques, such as fusion welding, helps professionals choose the best methods and materials for their specific projects. With advancements in welding technology, geomembranes continue to provide essential solutions for sustainable and secure containment systems across industries.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)