+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geosynthetic clay liners are widely used in civil and environmental engineering projects to control fluid migration and enhance containment systems. These engineered barriers are especially effective in applications such as landfills, mining, and wastewater treatment. This article addresses common questions about their use and benefits, helping engineers and project managers make informed decisions.

What Are Geosynthetic Clay Liners and How Do They Work?

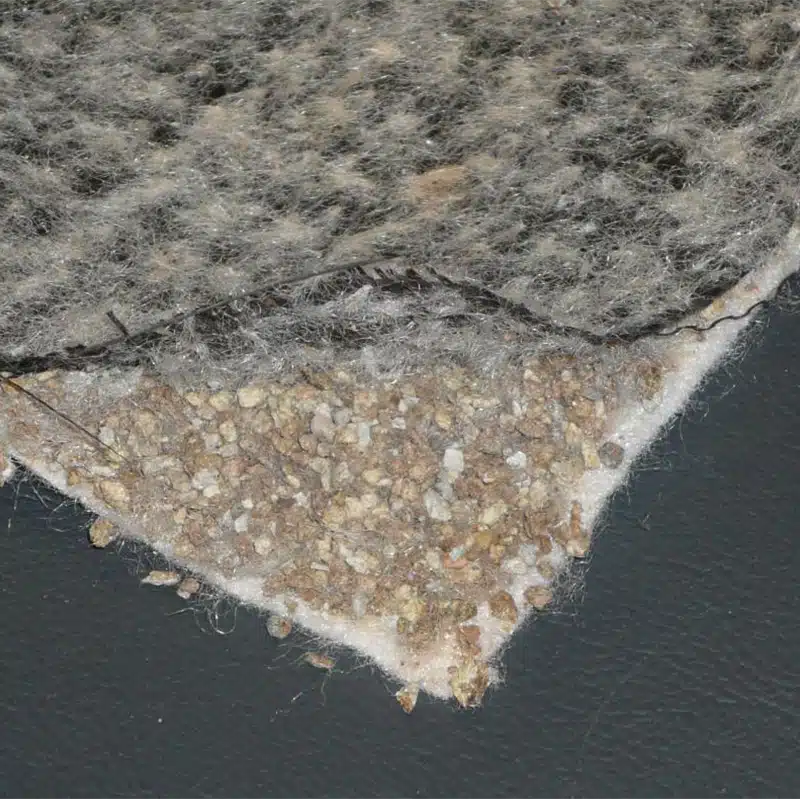

Geosynthetic Clay Liners (GCLs) are engineered materials used for environmental containment, consisting of a layer of bentonite clay between two geotextiles or bonded to a geomembrane. They work in several key ways:

- Hydraulic barrier – when hydrated, the bentonite swells to form a low-permeability seal that blocks fluid migration;

- Self-sealing – the clay naturally swells to fill small punctures or cracks, offering long-term leak protection;

- Easy installation – GCLs are thinner and lighter than traditional clay liners, requiring less equipment and labor;

- Environmental protection – commonly used in landfills, mining, and wastewater sites, they help prevent contaminants from leaching into soil and groundwater;

- Compatibility – they can be combined with geomembranes to enhance overall lining system performance.

What Problems Do GCLs Solve in Environmental Projects?

GCLs address several key challenges in environmental projects. Seepage and leakage prevention: GCLs provide a low-permeability barrier (often <1×10⁻⁹ m/s) that effectively prevents the migration of leachate, contaminated water, or chemicals into surrounding soil and groundwater.

- Containment of hazardous materials: In landfills, mining, and industrial sites, GCLs are used to line cells and caps to securely isolate waste and avoid environmental contamination.

- Replacement or supplement to compacted clay liners: GCLs solve space and construction constraints by offering thinner, lighter, and easier-to-install alternatives with equivalent or superior hydraulic performance.

- Slope stability and erosion control: GCLs conform to terrain and enhance slope protection when combined with geomembranes or vegetation.

- Resistance to differential settlement: Unlike rigid materials, GCLs are flexible and can tolerate minor ground movement without losing sealing performance.

- Installation efficiency and cost savings: They come in large rolls, are quick to deploy, and require less equipment and labor, reducing construction time and project cost.

When Should You Choose GCLs Over Traditional Clay Liners?

Geosynthetic Clay Liners (GCLs) are the preferred solution over traditional compacted clay liners in several practical and engineering-driven scenarios:

- Limited space or thickness constraints: GCLs provide an effective hydraulic barrier with minimal thickness, making them ideal where excavation depth is restricted or airspace must be maximized.

- Fast-track construction schedules: When rapid installation is required, GCLs outperform compacted clay liners by eliminating the need for moisture conditioning, lift placement, and intensive compaction.

- Consistent and predictable performance requirements: GCLs offer uniform permeability and factory-controlled quality, avoiding the variability often associated with natural clay sources.

- Challenging site conditions: At sites with weak subgrades, steep slopes, or irregular terrain, GCLs conform easily to the surface and maintain barrier integrity.

- Limited availability of suitable clay: In regions where high-quality clay is scarce or costly to import, GCLs provide a reliable and economical alternative.

- Composite liner systems: GCLs are commonly selected for use with geomembranes to form composite liners, enhancing leak protection and overall containment performance.

Choosing GCLs over traditional clay liners enables greater design flexibility, reduced construction risk, and long-term containment reliability, particularly in modern environmental and waste management projects.

How Durable Are GCLs in Harsh Environments?

GCLs are designed to withstand extreme environmental conditions. They maintain low permeability over time, resist chemical degradation, and are effective even under high load pressures. When properly installed and covered, they can provide long-term performance for decades, making them a reliable solution for containment systems.

Geosynthetic clay liners offer a powerful, flexible, and cost-effective solution for controlling fluid migration in various engineering applications. Their proven performance makes them an essential component of modern environmental protection systems.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)