+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

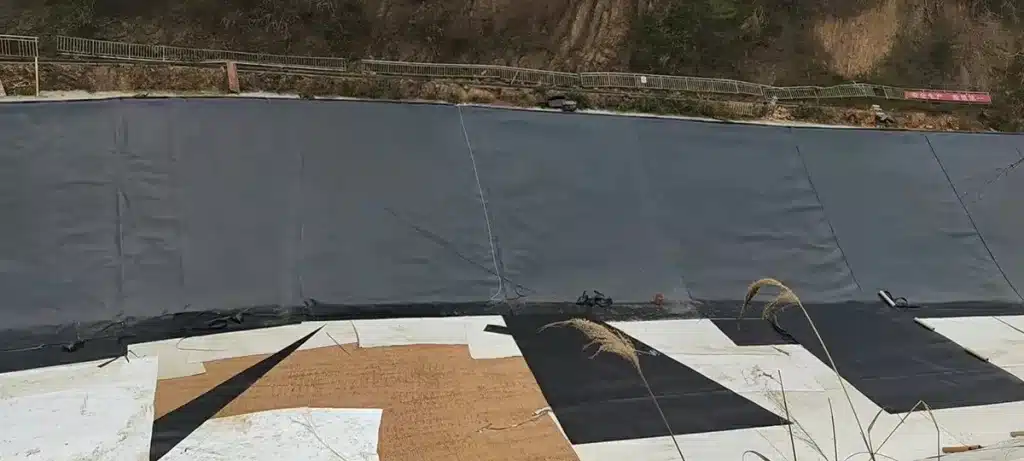

HDPE Geomembrane Installation is a critical process for projects that demand long-term containment, environmental protection, and regulatory compliance. In applications such as landfills, wastewater treatment, mining, and water storage, proper installation directly determines liner performance and service life. For project owners, EPC contractors, and procurement teams, selecting qualified installation solutions ensures chemical resistance, leak prevention, and structural integrity under harsh conditions. This guide outlines installation fundamentals, technical requirements, and key considerations to support informed purchasing and project planning decisions.

What is an HDPE Geomembrane Installation?

- Material: made from high-density polyethylene (HDPE) resins, offering chemical resistance and UV stability

- Structure: flexible, impermeable sheets designed to control fluid or gas migration

- Durability: long-lasting, resistant to environmental stress cracking and chemical degradation

- Applications: used in landfills (liners and caps), ponds and reservoirs, mining tailings containment, wastewater treatment, and agricultural water storage

- Performance: provides leak-proof containment and maintains integrity under high tensile stress and challenging environmental conditions

HDPE Geomembrane Installation is a core part of a geomembrane liner system, essential for projects requiring reliable fluid containment and environmental protection, offering decades of durable, impermeable performance when properly installed.

What are common challenges during HDPE geomembrane installation?

HDPE geomembrane installation can face several challenges that affect its performance and lifespan:

- Punctures or physical damage: occur during handling, transportation, or placement on rough subgrades.

- Seam welding issues: improper welding techniques or lack of quality control may cause seam failures and leaks.

- Poor surface preparation: uneven or debris-filled foundations can create wrinkles, stress points, and weak spots in the liner.

- Environmental conditions: wind, rain, and temperature fluctuations can interfere with welding and placement, reducing installation quality.

- Skill and equipment limitations: insufficiently trained labor or inadequate welding equipment may compromise the integrity of the installation.

Addressing these challenges through proper planning, site preparation, skilled labor, and quality assurance ensures a reliable and durable geomembrane system.

What are the benefits of HDPE geomembrane installation?

The benefits of HDPE geomembrane installation include:

- Leakage Prevention: HDPE geomembranes are impermeable, preventing the seepage of liquids or contaminants.

- Environmental Protection: They help contain hazardous materials, reducing the risk of soil and water contamination.

- Durability: HDPE geomembranes are long-lasting and resist chemical degradation and UV exposure.

- Cost-Efficiency: They require minimal maintenance, saving on long-term operational costs.

- Versatility: HDPE geomembranes can be used in a wide range of applications, from landfills and ponds to wastewater treatment facilities and reservoirs.

What are the benefits of HDPE geomembrane installation?

Ensuring the long-term performance of HDPE geomembranes requires proper post-installation practices and maintenance measures:

- Regular Inspections: Periodically check for punctures, seam integrity, and signs of stress or deformation to detect potential issues early.

- Protective Covering: Use soil, sand, or geotextile layers to shield the geomembrane from UV exposure, mechanical damage, or extreme temperatures.

- Proper Drainage Management: Maintain effective drainage systems to prevent water accumulation, which can cause hydraulic pressure and potential liner displacement.

- Avoiding Sharp Objects: Limit heavy machinery movement and remove debris from the liner surface to prevent accidental punctures.

- Seam Testing and Repair: Conduct nondestructive testing (such as vacuum box or air pressure testing) on seams to ensure complete weld integrity, and repair any defects immediately.

By following these measures, HDPE geomembranes can maintain their impermeability and structural integrity for decades, ensuring reliable containment and environmental protection.

In conclusion, HDPE geomembrane installation is a critical aspect of various construction and environmental projects. By following the proper installation procedures, you can ensure the integrity and longevity of your geomembrane, providing the necessary protection for your project.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)