+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geocells are an innovative and highly effective solution in modern highway construction. These three-dimensional, honeycomb-like structures made of geosynthetic materials are transforming the way roads are built and maintained. By providing enhanced stability, improved load distribution, and reduced soil erosion, geocells play a crucial role in creating durable, cost-effective highways. This article explores how geocells are revolutionizing road construction, answering key questions about their benefits, functionality, and various types.

What is geocell in road construction?

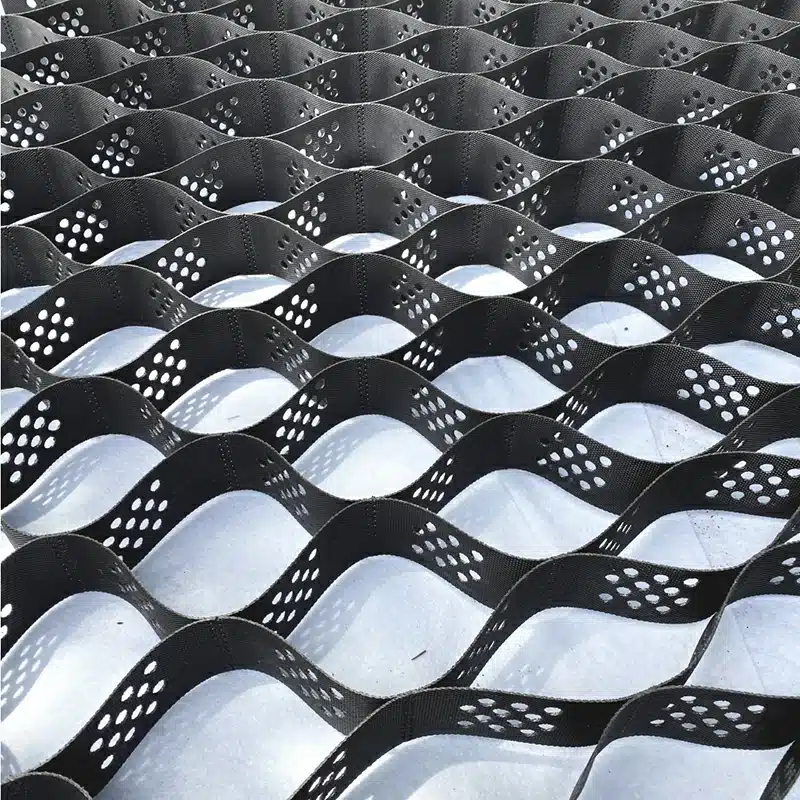

Geocell is a type of geosynthetic material designed as a three-dimensional cellular confinement system. It is typically made from high-density polyethylene (HDPE) or other polymer-based materials and features a three-dimensional mesh structure made of reinforced HDPE sheets, welded with high strength. In road construction, geocells are used to stabilize the foundation of roads by confining the soil and preventing lateral movement. The cellular structure of geocells allows for better compaction of the soil, which increases the overall strength and load-bearing capacity of the roadbed.

What are the benefits of geocells on roads?

Geocells offer several significant benefits in highway construction:

- Increased Stability: By confining the soil, geocells improve the structural integrity of the road, reducing settlement and the likelihood of road failure. They are flexible, durable, and able to bear heavy loads without damage, making them ideal for stabilizing road foundations.

- Enhanced Load Distribution: The cells in geocells distribute the load more evenly across the soil, reducing the pressure on the subgrade and preventing rutting or deformation of the road surface. Their flexible design ensures that they can adapt to shifting loads while maintaining road stability.

- Reduced Soil Erosion: Geocells help prevent soil erosion in areas where roads are exposed to water runoff, stabilizing the roadbed in flood-prone areas. Their durable structure helps maintain the integrity of the road even in challenging environments.

- Cost-Effectiveness: Geocells can reduce the need for costly materials like deep foundations or extensive drainage systems, making road construction more affordable. Their ability to bear heavy loads without damage also minimizes the need for frequent maintenance.

- Improved Drainage: The cellular structure facilitates better water flow, reducing the risk of water accumulation beneath the road and prolonging the lifespan of the highway. This feature contributes to both the durability and cost-effectiveness of roads built with geocells.

How does geocell work?

Geocells work by creating a confined environment for soil, which enhances its structural performance. When the geocell is expanded and placed on the subgrade, the cells fill with soil, which is then compacted. The structure holds all the infill materials in place and distributes any weight or pressure from above across the infill and the cell walls. This confinement prevents the soil from shifting horizontally under load, improving the road’s ability to bear weight. The system also reduces the vertical displacement of the soil, ensuring the road remains level and stable over time. Furthermore, the open structure allows water to drain through, reducing the risk of water damage beneath the road surface.

What are the different types of geocells?

There are various types of geocells used in highway construction, each designed for specific purposes:

- HDPE Geocells: Made from high-density polyethylene, these are the most commonly used type of geocell. They offer excellent resistance to UV radiation and chemicals, making them suitable for long-lasting road construction.

- Steel-Geocell Combinations: These geocells combine the flexibility of geocells with the strength of steel reinforcements. They are used in areas that experience heavy traffic or extreme conditions.

- PP (Polypropylene) Geocells: Made from polypropylene, these geocells are more eco-friendly and are suitable for projects in environmentally sensitive areas.

- Geocell Mats: These are pre-formed, compact geocell mats that can be quickly deployed on-site, making them ideal for time-sensitive construction projects.

- Non-Perforated and Perforated Geocells: Non-perforated geocells are designed to provide maximum confinement and stability for the soil, making them ideal for applications where soil movement needs to be strictly controlled. On the other hand, perforated geocells allow for better water drainage, making them suitable for areas where water flow is a concern, such as in flood-prone regions. Both types offer unique advantages depending on the specific needs of the project.

Geocell technology is a game-changer in the world of highway construction. These three-dimensional, cellular structures enhance the performance of roads by improving soil stability, load distribution, and drainage. Whether made from HDPE, polypropylene, or reinforced with steel, geocells offer a range of solutions tailored to different construction needs. The benefits of using geocells in road construction are clear: cost-effectiveness, increased road durability, and a reduced environmental impact. As the demand for sustainable infrastructure grows, geocells are sure to play an increasingly important role in shaping the roads of the future.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)