+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geocells are an innovative and versatile solution in the field of geotechnical engineering, offering a sustainable method to solve various soil stabilization problems. This article delves into the essential aspects of geocells, including their lifespan, functionality, application limits, and manufacturing process. By exploring these facets, we aim to provide a thorough understanding of geocells and their significance in modern engineering projects.

What is the lifespan of a Geocell?

The lifespan of a geocell can vary depending on factors such as the material used, environmental conditions, and the specific application. Generally, high-quality geocells made from durable materials like high-density polyethylene (HDPE) can last anywhere from 20 to 50 years or more when properly installed and maintained. Factors that contribute to their longevity include resistance to UV exposure, chemical degradation, and mechanical wear and tear from load-bearing applications. Proper installation, including adequate soil compaction and correct anchoring, also plays a crucial role in ensuring the longevity and effectiveness of geocells in various engineering applications.

Does Geocell Work?

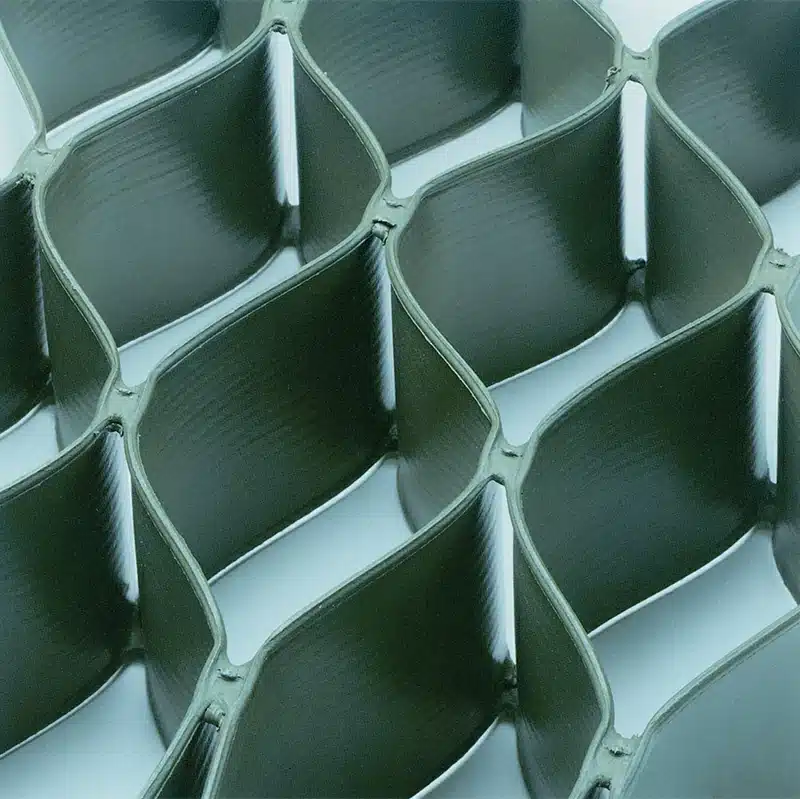

Yes, geocells are widely recognized for their effectiveness in various geotechnical applications. Geocells are three-dimensional cellular structures made from various materials like HDPE (high-density polyethylene) and can be filled with soil, aggregate, or concrete. They work by confining and stabilizing infill materials, providing support and reinforcement to the ground. Here are some key benefits and applications where geocells work effectively:

- Soil Stabilization: Geocells prevent soil erosion and enhance load distribution, making them ideal for stabilizing slopes and embankments.

- Retaining Walls: They can be used to construct retaining walls by confining soil or aggregate, providing structural stability and reducing the pressure on the wall structure.

- Road Construction: Geocells are used in road and pavement construction to improve load-bearing capacity, reduce rutting, and extend the lifespan of the road surface.

- Erosion Control: They are effective in erosion control applications, such as riverbanks and shorelines, by stabilizing soil and preventing sediment runoff.

- Green Infrastructure: Geocells support green infrastructure projects like green roofs and vegetated walls by providing a stable base for vegetation to grow.

Overall, geocells work by enhancing the mechanical properties of soils and aggregates, improving stability, and reducing construction costs compared to traditional methods.

What is the maximum slope for Geocell?

The maximum slope for Geocell typically ranges from 45 to 70 degrees, depending on various factors such as the type of Geocell used, the material filled within the cells, and the site-specific conditions like soil type and environmental factors. For steep slopes, additional engineering considerations such as anchoring, securing methods, and the use of geotextiles or geogrids for added reinforcement may be necessary to ensure stability and long-term performance.

How is Geocell Manufactured?

Geocells, also known as cellular confinement systems, are three-dimensional honeycomb-like structures made from high-density polyethylene (HDPE) or other polymer materials. These structures are widely used in civil engineering for soil stabilization, erosion control, and load support. The manufacturing process of geocells involves several steps, each crucial to ensuring the final product’s durability, flexibility, and effectiveness in various applications.

- Selection of Raw Material: The manufacturing of geocells begins with selecting the raw material, typically high-density polyethylene (HDPE) due to its excellent chemical resistance, UV stability, and mechanical properties. Other materials, like polypropylene or polymer composites, may also be used depending on the required performance characteristics.

- Extrusion of Polymer Sheets: Once the raw material is selected, it undergoes an extrusion process. In this step, the polymer material is melted and forced through a die to create thin, continuous sheets of plastic. These sheets are then cooled and cut into specific widths based on the geocell’s design specifications.

- Perforation: After extrusion, the plastic sheets are perforated. This involves punching small holes into the sheets, allowing for better drainage and increasing the flexibility of the geocell. The pattern and size of the perforations are designed to optimize the performance of the geocell in its intended application.

- Welding and Formation of the Honeycomb Structure: The perforated sheets are then arranged in a stack and subjected to a thermal welding process. The sheets are welded together at regular intervals, creating a honeycomb-like structure. This structure can be expanded or contracted, allowing for easy transportation and deployment on-site. The quality of the welding process is critical to ensure the strength and durability of the geocell.

- Cutting and Packaging: Once the geocell has been formed, it is cut into the desired sizes and shapes according to customer specifications. The finished geocells are then folded, packaged, and prepared for shipment. The packaging ensures that the geocells are protected during transportation and can be easily deployed at the construction site.

Geocells are manufactured through a process that involves the extrusion of polymer sheets, perforation, thermal welding, and cutting. The result is a flexible, durable, and versatile product used in various civil engineering applications to improve soil stability, prevent erosion, and support heavy loads. The careful selection of materials and precise manufacturing processes ensure that geocells meet the high standards required for their intended uses.

Geocells represent a significant advancement in geotechnical engineering, offering a durable, effective, and versatile solution for soil stabilization and erosion control. With a potential lifespan of up to 100 years, geocells provide a long-term solution for enhancing the load-bearing capacity of soils and stabilizing slopes. Their manufacturing process ensures that they are equipped to withstand harsh environmental conditions, making them a reliable choice for a wide range of engineering applications. Understanding the fundamentals of geocell technology, including its lifespan, effectiveness, slope capacity, and manufacturing process, is essential for professionals seeking sustainable and efficient solutions in soil stabilization projects.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)