+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

In the realm of environmental engineering and construction, the significance of geomembranes cannot be overstated. These plastic films serve as barriers to protect and preserve the natural environment. Geomembrane companies play a pivotal role in manufacturing these essential materials, employing advanced technologies and processes to meet the growing demands of various industries. This article delves into the world of geomembranes, exploring their composition, applications, manufacturing processes, and their critical function in safeguarding our planet.

What is the difference between a geomembrane and a geotextile?

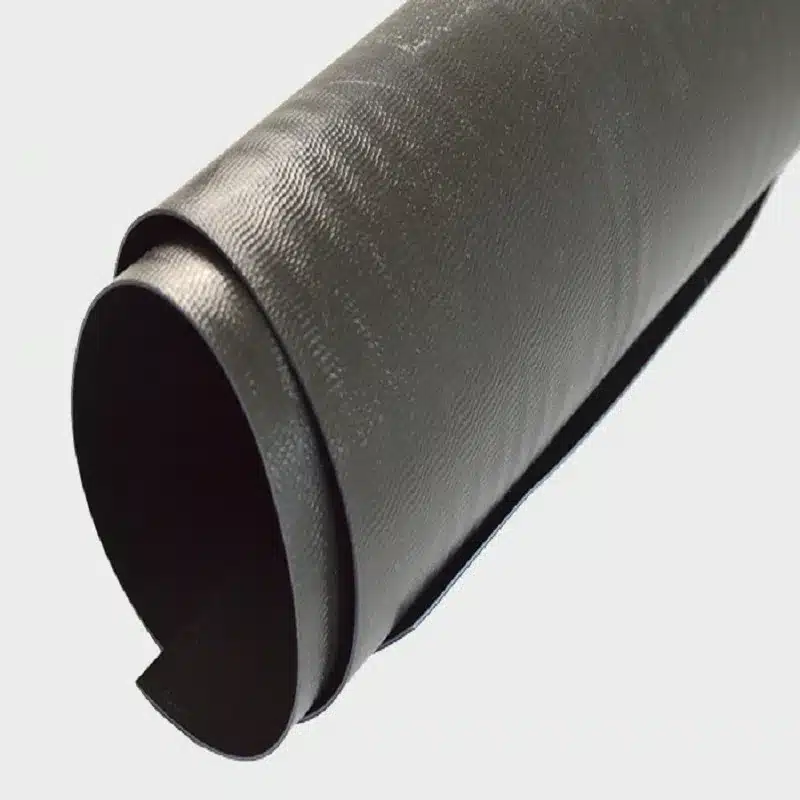

Geomembranes and geotextiles, though both crucial in environmental protection and engineering projects, differ significantly in their material composition and function. Specifically, geomembrane is a plastic film, and geotextile is a fiber cloth geotextile, highlighting the fundamental difference between the two. The former is a thin, impermeable barrier made from materials like polyethylene (PE), polyvinyl chloride (PVC), or ethylene propylene diene monomer (EPDM), designed to prevent the migration of contaminants or to contain liquids. The latter, in contrast, is a permeable fabric, either woven or non-woven, aimed at providing reinforcement, filtration, separation, or drainage in soil-related applications. This distinction underscores how geomembranes serve to block substances to prevent contamination, while geotextiles work to promote filtration and drainage, thereby making them complementary technologies in environmental and civil engineering projects.

How do geomembrane companies contribute to environmental protection?

Geomembrane companies are at the forefront of environmental protection, playing a pivotal role by manufacturing barriers specifically designed to stabilize earth and to secure landfills, ensuring the containment of hazardous or municipal wastes and their leachates. These innovative companies produce geomembranes that are indispensable in preventing pollutants from seeping into the soil and groundwater, thereby safeguarding ecosystems and human health. The use of geomembranes to contain waste materials effectively prevents their interaction with the natural environment. This critical function of geomembranes in waste management systems, mining operations, and water conservation projects underscores their significant contribution to the overarching goal of maintaining a clean and safe environment.

What is the extrusion casting process in the context of geomembrane production?

Geomembrane companies leverage the extrusion casting process as a cornerstone manufacturing technique to fabricate high-quality, durable plastic films. Central to this process is the melting of plastic resin pellets, which are subsequently extruded through a flat die, transforming the molten plastic into a thin film. This film is then rapidly cooled, solidifying into a sheet with precise control over its thickness and properties. The extrusion casting process is instrumental in ensuring that the produced geomembrane meets the diverse requirements of various applications. Its efficiency and versatility are highly valued, as they facilitate the creation of geomembranes that are not only robust and impermeable but also resistant to chemicals and environmental stressors, making it a preferred method among geomembrane companies.

How are geomembranes used in lining drainage systems and protecting against water seepage?

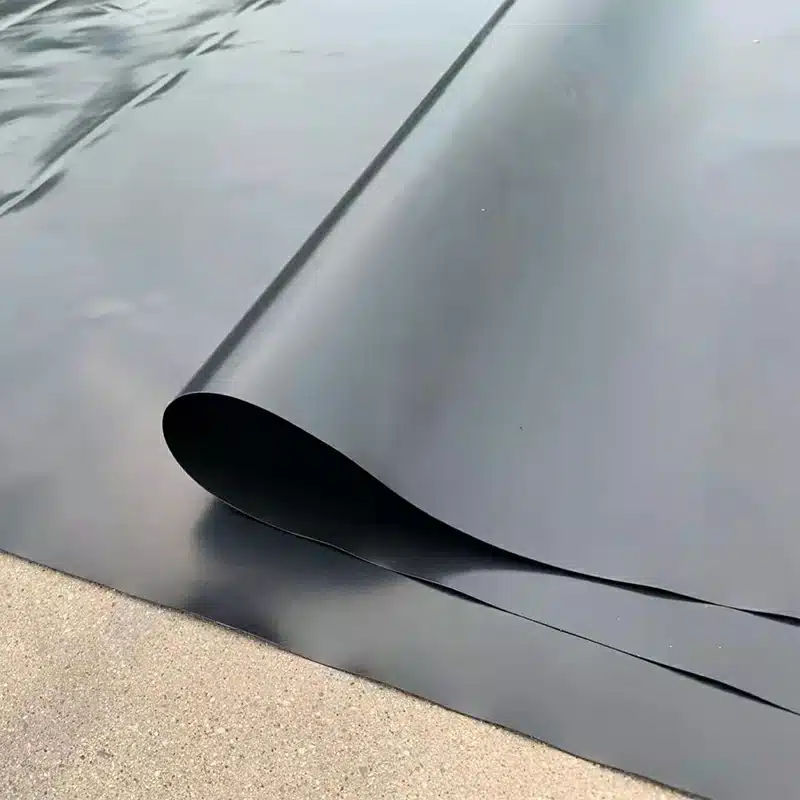

Geomembranes play a crucial role in lining drainage systems and protecting infrastructures from water seepage, thanks to their impermeable nature. This application is vital in drainage systems where geomembranes are instrumental in preventing the loss of water and safeguarding the surrounding soil from erosion and contamination. They are strategically installed along the sides and bottoms of drainage channels, reservoirs, or ponds, ensuring that water is efficiently collected and directed, thereby avoiding any potential damage or loss. Moreover, the use of geomembranes extends to the construction of dams, tunnels, and foundations, where their primary function is to prevent water seepage that could otherwise weaken structures and lead to costly damages. By serving as a robust barrier against water, geomembranes not only help maintain the structural integrity of various engineering projects but also significantly contribute to water conservation efforts, underscoring their importance in modern construction and environmental protection.

Geomembrane companies are instrumental in advancing environmental protection and sustainability. Through the production of geomembranes, these companies provide essential solutions for waste containment, water conservation, and infrastructure protection. By understanding the differences between geomembranes and geotextiles, the environmental benefits of geomembranes, the extrusion casting process, and their applications in lining and protection, we can appreciate the critical role these materials play in our efforts to safeguard the environment. As technology advances, geomembrane companies will continue to innovate, further enhancing their contributions to a sustainable future.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)