+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Anyone familiar with construction sites understands the myriad challenges they present: strict schedules unaffected by weather delays, escalating project expenses, labor shortages, and ever-changing environmental regulations.

Composite construction mats are engineered to tackle these daily obstacles by providing safe, durable site access over soft and unstable ground conditions while simultaneously cutting project costs.

Applications of Composite Construction Mats

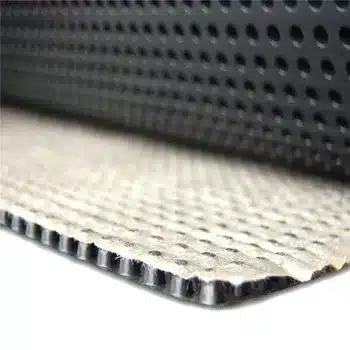

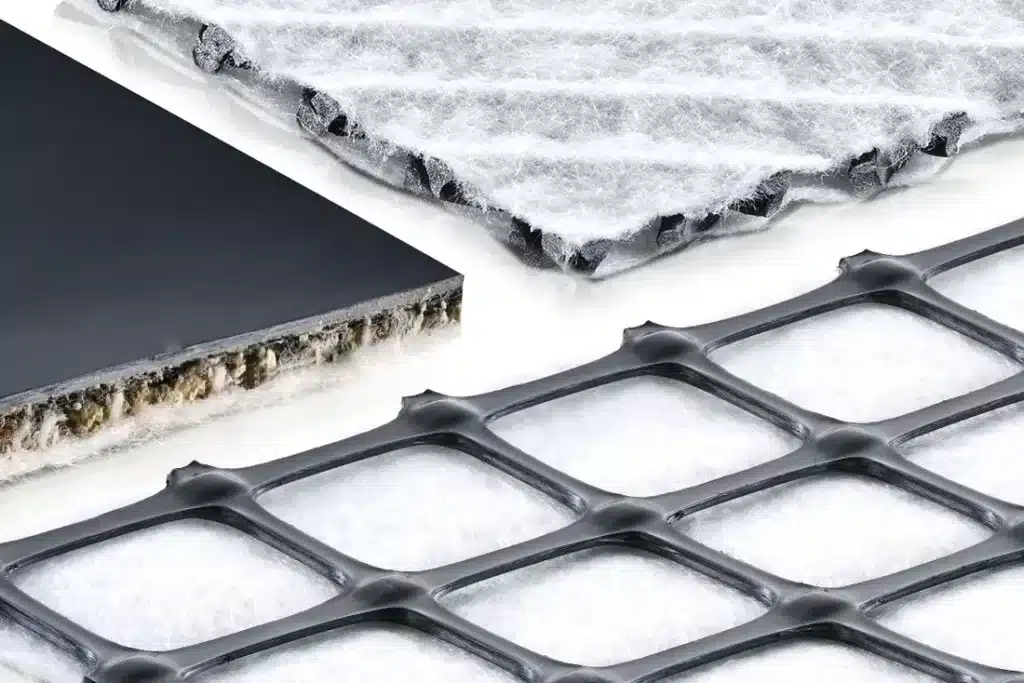

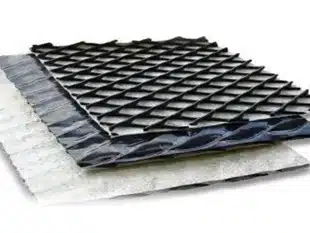

Composite construction mats, typically composed of high-density polyethylene (HDPE), serve a variety of purposes:

- Safeguarding prepared subgrades and unstable ground

- Enabling access over extremely soft terrain

- Creating temporary roadways

- Supporting oil rig, track, and crane operations

- Protecting drill sites with liner support

- Serving as staging areas, work platforms, and laydown yards

Enhancing Safety for Crews and Equipment

Geotextiles are permeable fabrics made from synthetic fibers, used for filtration, drainage, and erosion control. A geocomposite consists of a combination of one or more geosynthetics, specifically a geogrid, a geotextile, a geomembrane, and/or a geonet, with another material, such as geomembranes or drainage nets. This integration enhances their functionality to include both filtration and barrier properties, making them suitable for more demanding applications such as landfill liners and drainage systems.

Maximizing Return on Investment (ROI)

The cost of geocomposite liners varies depending on several factors including project size, material specifications, and installation requirements. Generally, geocomposites are more expensive than standalone geotextiles due to the added layers and functionalities. However, their cost-effectiveness stems from their ability to replace multiple traditional layers in certain applications, thereby reducing overall construction costs and enhancing long-term performance. For example, a typical geocomposite liner might cost around Rs 120/square meter, making it a competitive option in the realm of environmental containment solutions.

Environmental Benefits of Composite Construction Mats

Beyond their operational lifespan, composite mats are environmentally friendly. Made from HDPE, a non-toxic material, these mats do not splinter or crack, minimizing debris that could pollute the environment. They also prevent cross-contamination between work sites, protect vegetation, and control soil compaction, reducing cleanup time and costs.

Adaptability and Versatility

Flexibility is key on dynamic job sites. Composite construction mats can be assembled in various configurations—large work areas, passing lanes, or custom roadway layouts—allowing quick adaptation to changing project needs.

For construction site managers navigating diverse challenges, composite construction mats provide a versatile solution. From ensuring safe site access to minimizing environmental impact and optimizing cost efficiency, these mats prove indispensable in meeting the demands of modern construction projects.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)