+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Woven and nonwoven geotextiles provide essential solutions for soil reinforcement, drainage, filtration, and separation in civil engineering projects. As a trusted supplier, we offer high-quality woven and nonwoven geotextiles for bulk purchase, ensuring durability, high performance, and cost-effective installation. Ideal for roads, embankments, retaining walls, and drainage systems, these geotextiles meet diverse project requirements and long-term stability standards.

Woven and nonwoven geotextiles: Understanding Their Strengths and Uses

| Aspect | Woven Geotextiles | Nonwoven Geotextiles |

|---|---|---|

| Manufacturing | Woven threads | Bonded fibers |

| Strength | High tensile strength | High permeability |

| Applications | Soil stabilization, roads | Drainage, erosion control |

| Key Drawback | Limited permeability | Lower load resistance |

What is the difference between Woven and nonwoven geotextiles?

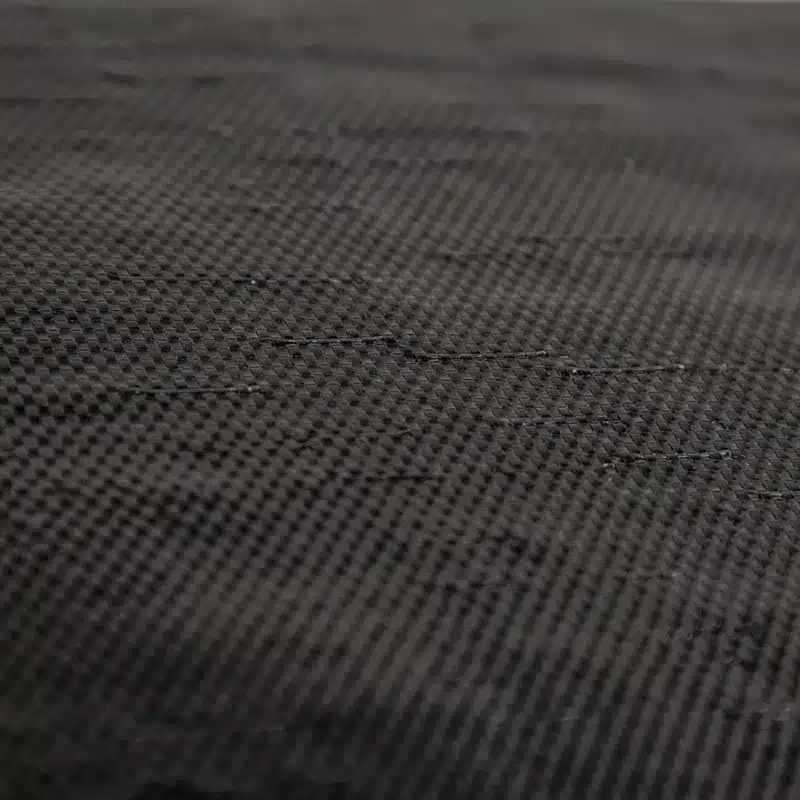

- Woven Textiles: Made by weaving threads together, creating a strong, durable fabric. Common in applications requiring strength, such as reinforcement in roads or embankments.

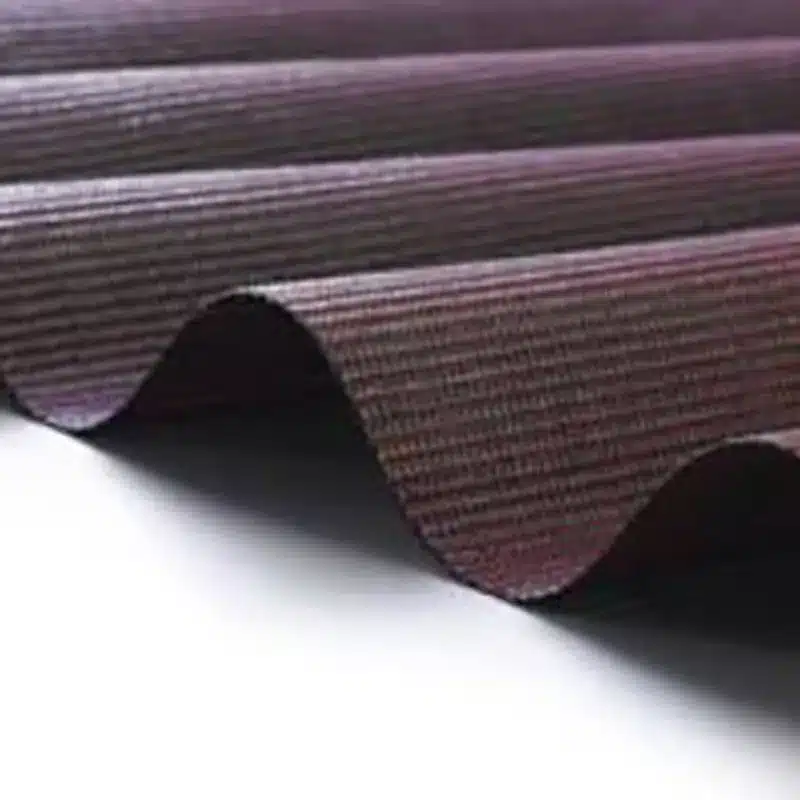

- Nonwoven Textiles: Made by bonding fibers with heat, pressure, or adhesives without weaving. Ideal for filtration, drainage, and erosion control.

Woven fabrics interlace yarns, while nonwoven fabrics bond fibers, giving each type distinct mechanical properties and uses.

What are the two main types of geotextiles?

| Woven Geotextiles | Non-Woven Geotextiles | |

| Structure | Made by interlacing fibers (usually polyester or polypropylene) in a regular pattern. | Typically used for applications requiring high tensile strength and load-bearing capacity, such as reinforcement in road construction, embankments, and retaining walls. |

| Uses | Made by bonding fibers together through mechanical, chemical, or thermal processes, without weaving. | Commonly used for filtration, drainage, separation, and erosion control in projects like landfills, drainage systems, and roads. |

Each type is designed for specific applications based on its different mechanical properties, including strength, permeability, and flexibility.

When Should You Choose Woven and nonwoven geotextiles?

Choose woven geotextiles for heavy-load reinforcement:

- High tensile strength and low elongation for road base stabilization, embankments, and retaining walls.

- Effectively distributes heavy loads.

- Limitation: Lower permeability, less suitable for drainage.

Choose nonwoven geotextiles for drainage and filtration applications:

- High permeability and flexibility for French drains, erosion control, and landscaping.

- Retains soil particles while allowing water flow.

- Limitation: Lower tensile strength, not recommended for heavy structural loads.

Woven and nonwoven geotextiles offer distinct advantages depending on the needs of a construction project. Woven geotextiles provide superior strength and are used for reinforcement, while nonwoven geotextiles excel in filtration and drainage applications due to their permeability. Understanding the differences between these two types of geotextiles helps in selecting the right material for specific engineering challenges.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)