+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

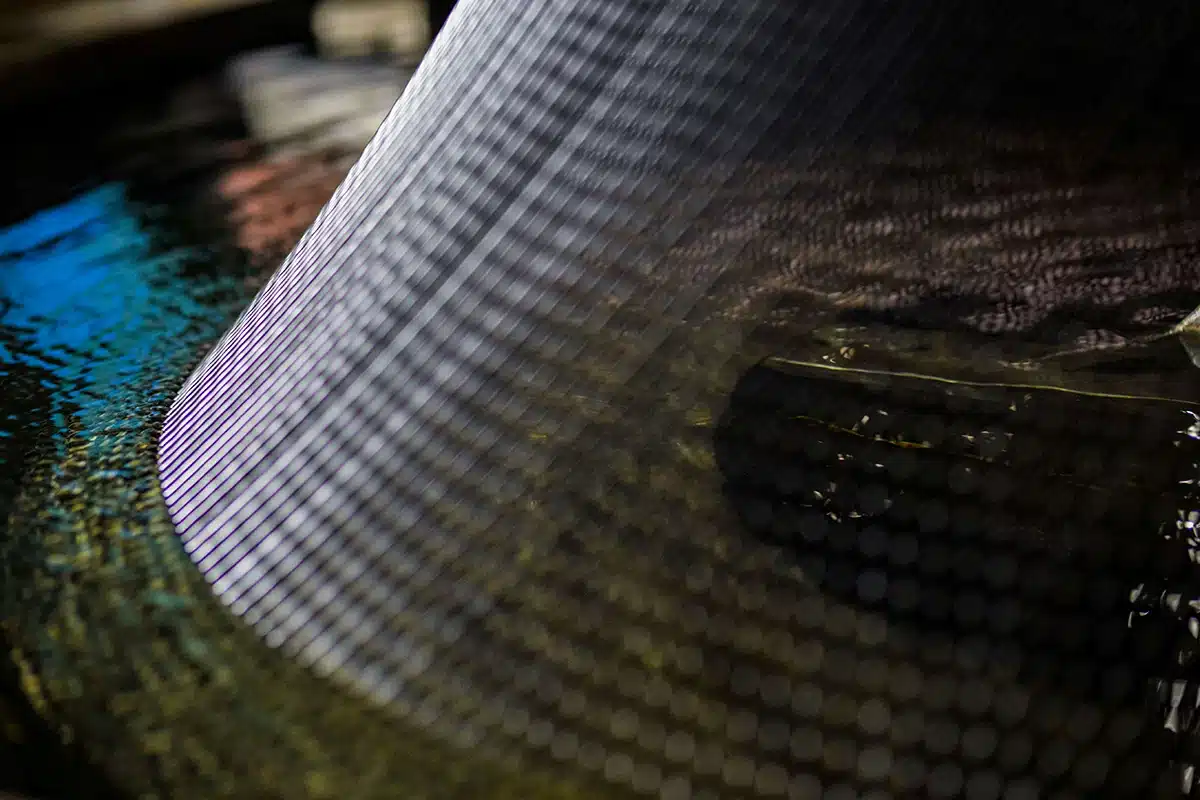

In the realm of civil engineering and construction, the quest for materials that combine durability, efficiency, and cost-effectiveness is unending. Among the myriad of innovations that have emerged, geonets hold a pivotal place, especially in applications related to drainage and erosion control. The geonet compression test, a crucial assessment method, plays a vital role in determining the suitability and performance of geonets in various environmental conditions. This article delves into the significance of this test, offering insights into how it’s conducted, its importance, and the implications of its results for construction and environmental projects.

What is a Geonet Compression Test?

The Geonet Compression Test is important for several reasons, particularly in the context of geosynthetics and civil engineering projects. Here are the key reasons why this test is significant:

- Assessment of Structural Integrity: The Geonet Compression Test evaluates the compressive strength and deformation characteristics of geonets under load. This information is critical to ensure that the geonets can withstand the expected pressures in their intended applications, such as in landfill liners, drainage systems, and other geotechnical structures.

- Quality Control: Manufacturers and engineers use this test as a quality control measure to verify that geonets meet the required specifications and standards. Consistent testing helps in maintaining product reliability and performance.

- Predicting Performance: By understanding how geonets behave under compression, engineers can predict their performance over time and under various environmental conditions. This is essential for designing durable and efficient drainage systems that prevent waterlogging and ensure stability.

- Design Optimization: The test results provide valuable data for optimizing the design of geosynthetic systems. Engineers can use this information to select the appropriate type and thickness of geonet for specific applications, balancing performance with cost-effectiveness.

- Safety and Compliance: Geonet Compression Tests ensure that the materials used in construction comply with industry standards and regulations. This is vital for safety, as substandard materials could lead to system failures and potential hazards.

- Longevity and Durability: Testing geonets under compression helps in evaluating their long-term durability. This is particularly important in applications where geonets are expected to remain functional for extended periods, such as in landfill covers and under roads.

- Environmental Impact: Accurate testing helps in designing geosynthetic solutions that minimize environmental impact. By ensuring that geonets perform well under compression, engineers can create more sustainable and effective drainage systems that manage water flow and reduce erosion.

- Economic Efficiency: Reliable performance data from the Geonet Compression Test can lead to more efficient use of materials and resources. This can result in cost savings by avoiding over-design and ensuring that the geonets are neither over-specified nor under-performing.

- Research and Development: The test provides essential data for the research and development of new geosynthetic products. Innovations in material composition and design can be tested and validated, leading to improved products that meet evolving engineering challenges.

In summary, the Geonet Compression Test is a crucial tool in the evaluation, design, and implementation of geosynthetic solutions in civil engineering. It ensures that geonets are fit for purpose, reliable, and contribute to the safety, efficiency, and sustainability of infrastructure projects.

How is the Geonet Compression Test Performed?

The Geonet Compression Test is performed to determine the compressive behavior of geonets, which are typically used for drainage in various geotechnical applications. Here’s a step-by-step outline of the procedure:

Preparation of Specimens:

- Specimen Size: Standard specimen size is usually 100 mm x 100 mm, but the size can vary based on the test standards or specific requirements.

- Conditioning: The specimens should be conditioned to a specified environment for a certain period to ensure consistency.

Test Setup:

- Testing Machine: A universal testing machine (UTM) capable of applying compressive loads is used.

- Plates: Two rigid plates are used to apply compressive force uniformly on the geonet specimen. The plates should be flat and smooth to ensure an even distribution of the load.

Placing the Specimen: Position the geonet specimen between the two plates in the UTM.

Applying the Load:

- Loading Rate: The compressive load is applied at a controlled rate, typically 1 mm/min to 10 mm/min, depending on the test standard.

- Loading Direction: The load is applied perpendicular to the plane of the geonet.

Measuring Deformation: As the load is applied, the deformation of the specimen is measured using displacement transducers or similar devices. The compressive force and corresponding deformation are recorded continuously.

Test Duration: The test is continued until a specified deformation (e.g., 50% of the original thickness) or until the geonet fails, depending on the test objectives.

Data Recording: The compressive load and corresponding deformation data are recorded throughout the test. This data is used to plot a load-deformation curve.

Analysis:

From the load-deformation curve, various parameters can be determined, such as:

- Compressive Strength: The maximum load the geonet can withstand before failure.

- Deformation Characteristics: The amount of compression the geonet undergoes under different loads.

- Stiffness: The initial slope of the load-deformation curve, indicates the rigidity of the geonet.

Reporting: The results are compiled into a report, including the compressive strength, deformation characteristics, and any observations about the failure mode of the geonet.

Standards and Guidelines: Various standards and guidelines can be followed for conducting the Geonet Compression Test, such as ASTM (American Society for Testing and Materials) standards. It’s important to follow the specific procedures outlined in the relevant standard to ensure consistency and comparability of results.

Safety and Precautions: Ensure the testing machine is properly calibrated. Handle the specimens and testing equipment with care to avoid damage. Follow safety protocols to prevent accidents during the test.

This test helps in evaluating the performance of geonets under compressive loads, which is crucial for their application in drainage systems, landfill liners, and other geotechnical projects.

Why is the Geonet Compression Test Important?

The Geonet Compression Test is a crucial procedure in geotechnical engineering due to several key factors:

Performance Assessment:

- Load-Bearing Capacity: The test evaluates how well a geonet can withstand compressive loads, which is vital for its performance in various applications such as landfill liners, roadbeds, and retaining walls.

- Deformation Analysis: It measures the extent of deformation under load, providing insights into the geonet’s structural integrity and reliability.

Durability Evaluation:

- Long-Term Stability: By simulating long-term compressive stresses, the test helps predict the geonet’s durability and lifespan under actual field conditions.

- Environmental Resistance: It assesses how environmental factors like temperature and moisture affect the geonet’s compressive strength and stability over time.

Quality Control:

- Manufacturing Consistency: Ensures that the geonets produced meet specified standards and perform uniformly across different batches.

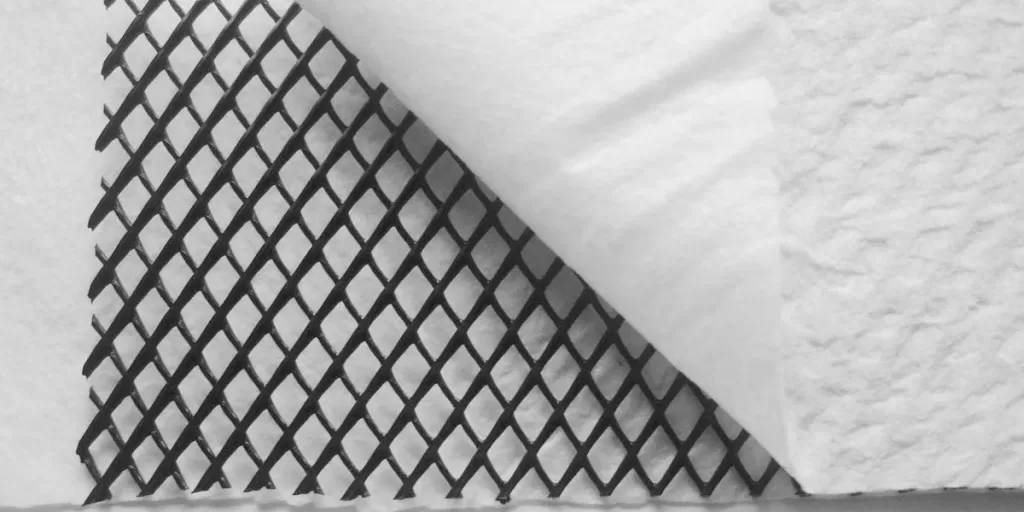

- Material Optimization: Helps in selecting the best materials and manufacturing processes to enhance the geonet’s performance.

Application Suitability:

- Project-Specific Customization: Provides data to customize geonets for specific projects, ensuring they meet the unique demands of different engineering applications.

- Regulatory Compliance: Ensures that the geonets comply with industry standards and regulations, which is crucial for project approvals and certifications.

Economic Impact:

- Cost-Effectiveness: By ensuring the geonet’s reliability and longevity, the test helps in reducing maintenance costs and extending the service life of engineering projects.

- Risk Mitigation: Minimizes the risk of geonet failure, which can lead to costly repairs and project delays.

In summary, the Geonet Compression Test is essential in geotechnical engineering for assessing the load-bearing capacity, durability, and overall performance of geonets. It plays a vital role in quality control, ensuring compliance with standards, and optimizing material usage for cost-effective and reliable engineering solutions.

What are the Implications of Geonet Compression Test Results?

The implications of Geonet Compression Test results are critical in several aspects:

Performance Evaluation:

- Load-Bearing Capacity: The test results indicate the load-bearing capacity of geonets, which is essential for their application in supporting various structures.

- Deformation Characteristics: Understanding how geonets deform under compression helps in assessing their suitability for specific uses, particularly in construction and environmental engineering.

Design Optimization:

- Material Selection: Results guide the selection of materials with optimal compression resistance, enhancing the durability and effectiveness of geonets.

- Structural Design: Engineers can refine the design of geonets to improve their structural integrity and performance under expected load conditions.

Application Suitability:

- Infrastructure Projects: In road construction, landfills, and retaining walls, the test results help in determining the best geonet configurations to ensure stability and longevity.

- Environmental Protection: For applications like erosion control and drainage systems, the compression test results ensure that geonets can withstand environmental stresses and maintain functionality.

Safety and Reliability:

- Risk Mitigation: By understanding the limits of geonets under compression, engineers can mitigate risks associated with structural failures, ensuring safety and reliability in their applications.

- Compliance with Standards: Compression test results help ensure that geonets meet industry standards and regulatory requirements, facilitating their approval and use in various projects.

The geonet compression test stands as a cornerstone in the assessment of geosynthetic materials, providing invaluable insights into their compressive strength and durability. By rigorously evaluating geonets through this testing, engineers can make informed decisions, ensuring the materials chosen meet the highest standards of performance and safety. As the construction and environmental sectors continue to evolve, the role of such tests in advancing material science and engineering becomes ever more critical, paving the way for more resilient and sustainable infrastructure.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)