+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

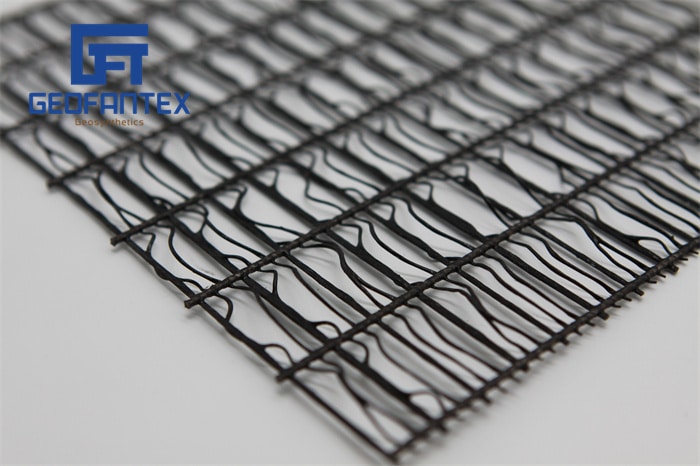

Polyester-woven geogrids are a pivotal component in modern construction, particularly in the reinforcement of soil. These geosynthetic materials, crafted from polyester yarns interwoven into a stable grid-like pattern, are not only used in environmental engineering, roads, and pavements but are also essential in applications such as soft and hard rock mining, as well as earthworks and foundations where extremely high tensile strength with low elongation is required. Their exceptional strength and durability make them an indispensable tool across a variety of demanding construction environments.

What is a Polyester Geogrid?

A polyester geogrid is a type of geosynthetic material designed for soil stabilization and reinforcement, offering a versatile and affordable solution for improving soil stability and reducing erosion. These geogrids are made from high-strength, low-elongation polyester yarns, which are knitted or woven into a uniform grid pattern and coated with a protective polymer. The grid’s structure helps to lock soil in place and distribute loads evenly, making it an essential material in civil engineering projects such as roadways, retaining walls, and levees.

What are the Three Types of Geogrids?

Geogrids can be broadly categorized into several types based on their manufacturing processes and material composition, including Uniaxial, Biaxial, Triaxial (Triax?), and Geogrid-Geotextile Composites:

- Uniaxial Geogrids: These are designed to provide strength in one direction and are typically used in wall and slope applications where primary stress is in a single direction.

- Biaxial Geogrids: Offering strength in both longitudinal and transverse directions, biaxial geogrids are used in applications like roadbed reinforcement where stress is more evenly distributed across two directions.

- Triaxial Geogrids: With a multi-directional structure providing enhanced stability and strength, triaxial geogrids are ideal for situations requiring multidirectional load distribution, such as in large-area foundations.

- Geogrid-Geotextile Composites: These combine the reinforcing properties of geogrids with the separation and filtration functions of geotextiles, enhancing overall performance in soil stabilization projects.

What is the Difference Between Geogrid and Geotextile?

Although both geogrids and geotextiles are used in soil reinforcement and stabilization, they differ significantly in their structure and functionality:

- Geogrids are characterized by their open grid-like structure, which allows for interlocking with surrounding soil and aggregates. This design is particularly effective in reinforcing and stabilizing soil while facilitating the transfer of forces.

- Geotextiles, on the other hand, are permeable fabrics made from fibers that can be woven or non-woven. They primarily function to separate layers of soil, filter water, and prevent soil erosion, without specifically enhancing load-bearing capacity.

What are the Benefits of Geogrids?

Geogrids offer several benefits in construction and engineering projects, including:

- Increased Load Capacity: By effectively distributing loads, geogrids enhance the load-bearing capacity of the soil, making structures more durable and resilient. They provide good resistance against chemicals, bacteria, and tensile strength, which contributes to their effectiveness in various environments.

- Cost Efficiency: They reduce the need for natural aggregate fill materials, which lowers construction costs and speeds up project timelines.

- Environmental Benefits: Geogrids contribute to environmental sustainability by stabilizing recycled materials for use in construction, thereby reducing waste and dependency on virgin materials.

- Versatility: Suitable for a variety of engineering applications, geogrids can be used in everything from roads and parking lots to embankments and landfills. Their chemical and bacterial resistance adds to their versatility, making them ideal for diverse and challenging construction scenarios.

Polyester woven geogrids play a crucial role in the field of geotechnical engineering, providing essential support and stability for various infrastructure projects. By understanding the different types of geogrids, their distinct advantages over other geosynthetic materials like geotextiles, and their wide range of benefits, professionals in the construction and civil engineering industries can make informed decisions about the most effective materials for their specific needs. As technology advances, the development and application of geogrids are likely to expand, further enhancing their significance in building sustainable and robust infrastructure.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)