+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Over the years, we’ve assisted countless homeowners and contractors in proper French drain installation and selecting the best fabric materials. Many calls come from frustrated individuals needing to replace failed drainage systems. Here’s a compiled list of the most frequent French Drain Mistakes to help you steer clear of these pitfalls.

Not Calling Before You Dig

The phrase “Not Calling Before You Dig” typically refers to the risks and consequences of starting excavation or digging projects without first notifying local utility companies. This step is crucial to avoid accidentally damaging underground utilities, such as gas lines, water pipes, electrical cables, and telecommunications lines.

When people or companies undertake digging projects, they may inadvertently strike underground utilities if they haven’t confirmed their locations first. This can lead to dangerous situations, including gas leaks, power outages, and water main breaks. Additionally, these accidents can result in significant fines, repair costs, and legal liabilities. The solution to this problem is simple: before starting any digging project, one should call a local “Call Before You Dig” service, often accessed by dialing 811 in the United States. This service sends out professionals to mark the locations of any underground utilities so that the digging can be done safely.

Risks of Not Calling Before You Dig

- Personal Injury: Striking a gas line or electrical cable can lead to explosions, fires, or electrocution, putting workers and nearby individuals at risk.

- Property Damage: Hitting a water pipe or sewer line can cause flooding, structural damage to buildings, and environmental contamination.

- Service Disruptions: Damaging utility lines can lead to outages affecting homes and businesses, sometimes over a wide area.

- Financial Consequences: Repairing damaged utilities can be costly, and the responsible party may be liable for these expenses. Additionally, fines for not following local regulations can be significant.

- Legal Liability: Failure to call before digging may result in lawsuits or penalties from both the utility companies and affected individuals or businesses.

Benefits of Calling Before You Dig

- Safety: Ensures that all underground utilities are located and marked, minimizing the risk of injury.

- Cost Savings: Prevents costly damages and the resulting financial burden of repairs.

- Compliance: Helps adhere to local regulations and avoids fines or legal consequences.

- Peace of Mind: Knowing that the digging project is proceeding with all necessary precautions.

What to Expect When You Call

When you contact the “Call Before You Dig” service, you’ll need to provide details about your project, including the location and scope of the work. Within a few days, professionals will visit your site to mark the locations of any underground utilities using colored flags or spray paint. Each color corresponds to a different type of utility (e.g., red for electric, yellow for gas, blue for water), helping you identify areas to avoid.

Skipping the call before digging can have serious consequences, from personal injury to financial and legal troubles. It’s a simple, free service that ensures safety and compliance with regulations, making it an essential step for any excavation project, no matter the size.

If you have a digging project planned, always remember to call before you dig—it’s a small step that can prevent big problems.

Using the Wrong Type of Drain Rock

Using the wrong type of drain rock can lead to ineffective drainage, water buildup, and even structural damage in various construction and landscaping projects. Drain rock, also known as drainage gravel, is an essential component in systems designed to manage water flow, such as French drains, retaining walls, and foundation drains. Selecting the right type of drain rock is crucial to ensuring that these systems function properly.

Drain rock is a type of gravel that is specifically used for drainage purposes. It typically consists of clean, washed stone that is free of fines (small particles like sand or clay) that could clog the drainage system. The wrong type of drain rock can impede water flow, cause clogs, or fail to provide adequate support for the surrounding structure. Factors like size, shape, and material of the drain rock are all critical considerations when choosing the appropriate type for a particular project.

Consequences of Using the Wrong Type of Drain Rock

- Poor Drainage: If the drain rock is too small or contains fines, it can compact too tightly and restrict water flow, leading to water buildup and potential flooding.

- Clogging: Fines in the rock can easily clog the drainage system, rendering it ineffective and requiring costly repairs or replacements.

- Structural Damage: Inadequate drainage can lead to water accumulation, which may cause erosion, weaken foundations, or increase hydrostatic pressure against retaining walls.

- Increased Maintenance Costs: Poor drainage can necessitate frequent maintenance to clear clogs or address water damage, increasing the long-term costs of the project.

- Environmental Issues: Improper drainage can lead to water pooling, soil erosion, and contamination of local water sources, affecting the surrounding ecosystem.

Choosing the Right Type of Drain Rock

- Size: The size of the drain rock is a crucial factor. Typically, drain rock ranges from 3/4 inch to 1 1/2 inches in size. The larger the rock, the better it will be at allowing water to flow through, but it must also be compatible with the scale of the drainage system.

- Shape: Angular rocks are usually preferred because they lock together better than rounded rocks, providing more stability while still allowing water to flow through the voids between them.

- Material: Drain rock is often made from materials like crushed granite, limestone, or other durable stones. The material should be clean and free from organic matter, which can decompose and cause clogging.

- Cleanliness: It’s essential to use washed rock that is free from fines, silt, or clay. These materials can compact and block the flow of water, leading to ineffective drainage.

Applications and Specific Considerations

- French Drains: French drains require a layer of drain rock to surround the perforated pipe. The rock should be of a size that allows water to flow freely while preventing soil from clogging the system.

- Retaining Walls: Drain rock is used behind retaining walls to reduce hydrostatic pressure. It should be angular and properly sized to ensure it doesn’t wash out and that it effectively channels water away from the wall.

- Foundation Drains: Proper drain rock helps to keep water away from a building’s foundation, preventing water damage and soil erosion. The rock should be large enough to facilitate good water flow and drainage away from the foundation.

Using the wrong type of drain rock can compromise the effectiveness of your drainage system, leading to significant problems such as poor water flow, structural damage, and increased maintenance costs. To ensure the success of your project, it’s essential to choose the correct type of drain rock, considering factors like size, shape, material, and cleanliness. Proper selection and installation of drain rock can save time, money, and headaches down the road, ensuring that your drainage system performs as intended.

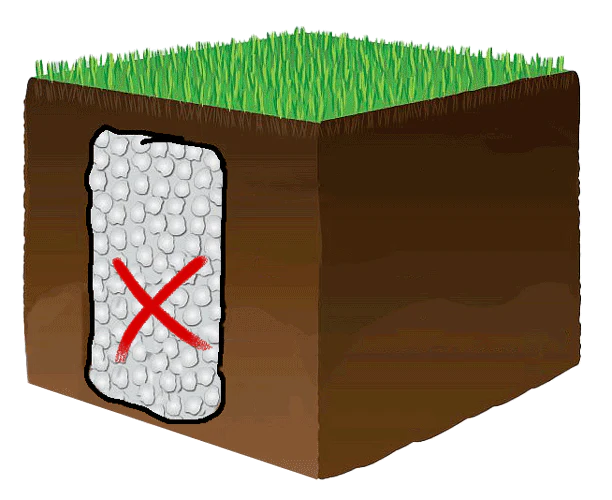

Not Lining the Trench with Drainage Fabric

Not Lining the Trench with Drainage Fabric: Is It a Good Idea?

When installing a French drain or any other drainage system, using drainage fabric (often made of non-woven geotextile) to line the trench is a commonly recommended practice. This fabric helps to prevent soil and sediment from clogging the drain, ensuring the system remains functional over time. However, there are cases where some opt not to use drainage fabric. Let’s explore the potential impacts of not lining the trench with drainage fabric.

What Happens If You Don’t Line the Trench with Drainage Fabric?

If you choose not to line the trench with drainage fabric, the main risk is sediment infiltration. Over time, fine particles from the surrounding soil can enter the drain, potentially clogging it and reducing its effectiveness. This can lead to water buildup, causing issues like soil erosion, water pooling, and foundation damage.

Are There Situations Where Lining the Trench Is Unnecessary?

In certain soil conditions, such as in areas with very coarse, sandy soils that naturally drain well, lining the trench might be less critical. However, even in these situations, not using a drainage fabric increases the risk of sediment entering the drain over time.

Can Alternatives to Drainage Fabric Be Effective?

Some installers use gravel-only systems, relying on the size and placement of the gravel to prevent sediment infiltration. While this can work in specific conditions, it’s generally less reliable than using a fabric. The gravel might eventually shift or become compacted, allowing fine particles to enter the drain.

What Are the Long-Term Consequences of Not Using Drainage Fabric?

Over the long term, not using drainage fabric can lead to system failure. Clogged drains can cause water to back up, leading to saturated soil, increased hydrostatic pressure on foundations, and potential structural damage. Repairing a clogged or failed drain is often much more costly than installing it correctly in the first place.

While it might seem like a minor step, lining the trench with drainage fabric is crucial to the longevity and effectiveness of a drainage system. Skipping this step can lead to significant problems down the line, making it a risk not worth taking. Even in cases where the soil seems well-draining, the peace of mind and protection that a drainage fabric provides make it an essential component of any drainage installation.

Selecting the Wrong Type of Landscape Fabric

Landscape fabric is a crucial element in many gardening and landscaping projects, acting as a barrier to prevent weed growth while allowing water and nutrients to pass through. However, not all landscape fabrics are created equal. Selecting the wrong type can lead to ineffective weed control, poor plant health, and even soil erosion. Here’s what you need to know about the importance of choosing the right landscape fabric for your project.

What Are the Different Types of Landscape Fabric?

Landscape fabrics generally fall into two categories: woven and non-woven.

- Woven Fabrics: Made from tightly woven plastic fibers, these fabrics are durable and allow water to pass through while blocking weeds. They are best suited for long-term applications like pathways, patios, and areas with heavy foot traffic.

- Non-Woven Fabrics: These fabrics are usually made from polypropylene or polyester and are less permeable than woven fabrics. They are ideal for use under rocks, mulch, or in areas where weed control is the primary concern.

- Spun-Bonded Fabrics: A hybrid type, these fabrics combine the benefits of both woven and non-woven fabrics, providing good permeability and weed control.

What Happens If You Choose the Wrong Fabric?

Choosing the wrong type of landscape fabric can have several negative consequences:

- Ineffective Weed Control: If the fabric is too permeable, it may allow weeds to grow through it. On the other hand, if it’s too dense, it could suffocate your plants by blocking essential water and nutrients.

- Soil Erosion: In areas prone to erosion, using a fabric that doesn’t provide adequate support can result in soil displacement, leading to unstable planting areas.

- Poor Drainage: Non-woven fabrics with low permeability can lead to water pooling on the surface, causing root rot and other water-related issues for plants.

- Shortened Lifespan: Using a fabric that’s not designed for your specific application can result in faster degradation, requiring you to replace it more frequently.

How to Choose the Right Landscape Fabric?

When selecting landscape fabric, consider the following factors:

- Purpose: Identify whether your primary goal is weed control, soil stabilization, or erosion prevention. Choose a fabric that aligns with these needs.

- Soil Type: The type of soil you have can influence your choice. For example, heavy clay soils might require a fabric with higher permeability to prevent waterlogging.

- Durability: For areas with high traffic or where the fabric will be exposed to sunlight, opt for a UV-resistant, durable fabric to ensure a longer lifespan.

- Plant Needs: Consider the water and nutrient requirements of the plants you’re working with. A fabric that’s too dense can hinder their growth, while one that’s too permeable might not provide adequate weed control.

Selecting the right type of landscape fabric is essential to the success of your landscaping project. The wrong choice can lead to ineffective weed control, poor drainage, soil erosion, and other issues that can compromise the health of your plants and the stability of your landscape. By understanding the different types of fabrics and considering your specific needs, you can make an informed decision that will help ensure the long-term success of your project.

Placing Excavated Soil Back into the Trench

When placing excavated soil back into a trench, it’s important to follow specific steps to ensure the soil is compacted properly and that the trench is restored safely and efficiently. Here’s a guide to help you do it right:

- Check the trench for stability: Before placing soil back, ensure that the trench walls are stable, and any utilities, drainage systems, or pipes within the trench are in good condition and positioned correctly.

- Backfill in layers: Place the excavated soil back into the trench in layers (typically around 6-12 inches thick). Compact each layer properly before adding the next one. This prevents future settling and maintains the stability of the backfilled trench.

- Compaction: Compact the soil using a mechanical compactor or by manual means to eliminate voids. This ensures proper support for any infrastructure above and helps prevent sinkholes or other ground failures.

- Restore topsoil: If the top layer was originally fertile topsoil, make sure this layer is returned last to maintain any landscaping or vegetation.

- Check for proper grading: After the trench is filled, ensure the surface is graded properly to promote water drainage and avoid ponding in the area.

By following these steps, the trench will be properly backfilled, preventing settlement and ensuring structural stability.

Lack of Positive Slope for the Drain

A lack of positive slope for the drain refers to the absence of a proper slope that allows water to flow away from a structure or area efficiently. In drainage systems, a positive slope means that the ground or piping is angled in such a way that water is directed toward an appropriate outlet, like a storm drain or a sewer, without pooling or backing up.

When there is no positive slope in place, water can accumulate, leading to various problems:

- Standing water: This can result in flooding, erosion, and damage to surfaces or foundations.

- Soil Saturation: The excess moisture can cause soil to become unstable, which may impact the stability of surrounding structures.

- Mold and Mildew: Improper drainage around buildings can lead to moisture infiltration, encouraging the growth of mold and mildew indoors.

- Foundation Damage: Over time, poor drainage can lead to cracks and other forms of structural damage to building foundations.

To correct this issue, it’s essential to create a proper gradient, typically a slope of 1-2% away from structures, to ensure that water flows efficiently. Techniques like installing French drains, grading the soil, or using geosynthetic materials (e.g., geotextiles) in conjunction with drainage systems can help manage and direct water flow.

Gravel Only Drain without a Drain Pipe

Including a perforated drain pipe surrounded by round drain rock is crucial for effectively managing water flow. A drain pipe prevents water pooling and directs surface and subsurface water away from structures.

Final Thoughts

By avoiding these common pitfalls during installation, you can prolong the lifespan of your French drain system and avoid future repairs. Consult a local landscaping or waterproofing expert for your area and drainage needs.

If your project requires non-woven fabric, explore our selection of professional-grade options perfect for French drain applications. Feel free to contact us for any drainage fabric inquiries or to place an order by phone.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)