+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

In the world of civil engineering and geotechnical applications, geocells and geogrids play crucial roles in soil stabilization, erosion control, and load distribution. The geocell is a deep, three-dimensional mesh structure, while the geogrid is typically two-dimensional, reflecting their distinct functions. Although both are geosynthetic materials designed to reinforce and stabilize soils, they function differently and are suited to different applications. This article explores the key differences between geocells and geogrids, how they work, and when to use each for optimal results.

What is the difference between geocell and geogrid?

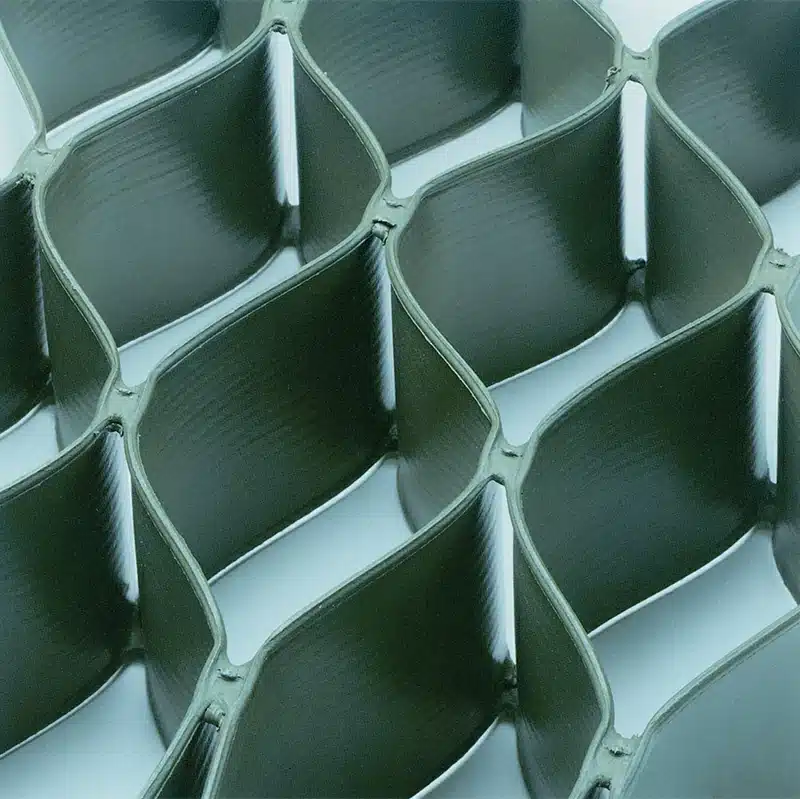

The primary difference between geocells and geogrids lies in their structure and function. Geocells are three-dimensional honeycomb-like structures made from high-density polyethylene (HDPE) or other polymers. They create a cellular confinement system that holds and stabilizes the infill material, such as soil or gravel, making them ideal for slope protection, retaining walls, and load-bearing applications. In summary, geogrids primarily provide tensile reinforcement to soils, enhancing their stability, while geocells confine and stabilize granular materials within their cells, creating a rigid structure. Geogrids are grid-like and focus on reinforcement, while geocells are cellular structures that confine fill material.

Do geocells work?

Yes, geocells are highly effective in soil stabilization and erosion control. They work by confining the infill material within their cells, preventing lateral movement and enhancing the load-bearing capacity of the soil. Geocells are an effective way to support heavy loads on weak soils, creating a stable and solid base even on slopes or soft soils. They are commonly used in projects where soil erosion, slope instability, or heavy loads are a concern, such as in the construction of retaining walls, embankments, and unpaved roads.

What do you fill geocell with?

Geocells can be filled with various materials depending on the application. Common infill materials include soil, sand, crushed stone, gravel, and even concrete. The choice of infill material depends on the project’s specific requirements. For instance, gravel or crushed stone is often used in road construction for enhanced load distribution, while soil or sand might be used in landscaping or slope protection applications.

When to use Geocell?

Geocells are particularly useful in situations where soil stabilization, erosion control, and load distribution are critical for protecting structures. You should consider using geocells in the following scenarios:

- Slope Protection: Geocells effectively prevent soil erosion on slopes and embankments, safeguarding the integrity of nearby structures.

- Retaining Walls: They provide additional stability to retaining walls, especially in areas prone to erosion or where heavy loads are expected, offering crucial protection for structures.

- Load Support: Geocells are ideal for constructing unpaved roads, parking areas, and foundations on soft or weak soils, ensuring the structures built on them remain secure.

- Channel Protection: They help stabilize channels and prevent erosion in waterways and drainage ditches, thereby protecting adjacent structures from potential damage.

Geocells and geogrids are both essential tools in civil engineering, each with unique properties and applications. While geocells offer three-dimensional confinement for soil stabilization and erosion control, geogrids provide tensile strength and load distribution in two dimensions. Understanding the differences between these materials and their specific applications can help engineers and builders make informed decisions for their projects, ensuring durability and stability in various construction environments.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)