+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geotextile filters are innovative materials that play a crucial role in various civil engineering and environmental applications. Used primarily for soil separation, drainage, and filtration, geotextile filters help maintain the integrity of construction projects by preventing soil erosion while allowing water to pass through. These filters are essential in a wide range of infrastructure projects, including road construction, landscaping, and water management systems. This article will answer key questions about geotextile filters to better understand their functionality, importance, and application.

What is a geotextile filter?

The performance of geotextile filters is determined by several key filter criteria, including permeability, particle retention, porosity, and thickness.

- Permeability: The geotextile must allow water to pass through easily while restricting soil movement. This is commonly evaluated by flow rate or the coefficient of permeability.

- Particle Retention: The geotextile must retain soil particles larger than its pore openings to prevent soil migration and clogging. This property is typically measured using standards such as ASTM D4751, which defines the apparent opening size (AOS).

- Porosity: The fabric must have adequate pore space to support continuous water flow while maintaining effective soil retention. Proper porosity ensures long-term filtration performance.

- Thickness: The geotextile must be thick enough to provide durability and filtration but not so thick that it restricts water flow. A balanced thickness supports both strength and permeability.

What are the filter criteria for geotextiles?

The effectiveness of a geotextile filter depends on meeting four fundamental filter design criteria, which ensure proper drainage performance while preventing soil loss over time:

- Permeability Criterion: The geotextile must allow water to pass through at a rate equal to or greater than the surrounding soil. Adequate permeability prevents excess pore water pressure buildup and ensures efficient drainage. This property is commonly evaluated using permittivity or the coefficient of permeability.

- Retention Criterion: The geotextile must retain soil particles while allowing water to flow freely. This is controlled by the fabric’s pore size, typically defined by the Apparent Opening Size (AOS) in accordance with ASTM D4751. Proper retention prevents soil migration, piping, and internal erosion.

- Porosity Criterion: Sufficient porosity is required to maintain long-term filtration performance. A well-designed pore structure minimizes clogging while sustaining continuous water flow under varying hydraulic conditions.

- Thickness Criterion: The geotextile must have adequate thickness to provide durability, cushioning, and filtration stability, without excessively restricting water flow. Appropriate thickness contributes to resistance against puncture, compression, and installation damage.

Together, these criteria ensure that the geotextile functions as a reliable filter layer, balancing water permeability, soil retention, and long-term performance in drainage and filtration applications.

Can water pass through geotextile fabric?

- Water Flow Criterion: The geotextile must allow water to pass through efficiently while preventing soil migration. Adequate water flow ensures proper drainage and avoids the buildup of excess pore water pressure. This property is evaluated based on the fabric’s permeability, density, and structure.

- Soil Retention Criterion: The geotextile must retain soil particles larger than its pore openings while permitting water flow. Proper soil retention prevents erosion, piping, and internal soil movement, maintaining the stability of the project.

- Filtration Continuity Criterion: Sufficient permeability and pore structure are required to maintain continuous water flow over time. A well-designed geotextile minimizes clogging and supports long-term filtration performance under varying hydraulic conditions.

- Durability Criterion: The geotextile must withstand hydraulic forces, installation stress, and environmental conditions without losing filtration performance. Adequate durability ensures that water can flow freely through the fabric throughout the lifespan of the project.

Together, these criteria ensure that geotextile filters effectively allow water passage while maintaining soil separation and long-term drainage performance.

¿Cuál es el grosor del geotextil para filtración?

El grosor del geotextil para filtración depende del tipo de aplicación, las condiciones hidráulicas y los requisitos mecánicos del proyecto. La selección adecuada busca un equilibrio entre permeabilidad, resistencia y durabilidad a largo plazo.

Factores clave que determinan el grosor

- Peso del material (gramaje): El geotextil suele clasificarse por peso, como 2 oz, 4 oz, 6 oz y 8 oz por yarda cuadrada, lo que influye directamente en su espesor y resistencia.

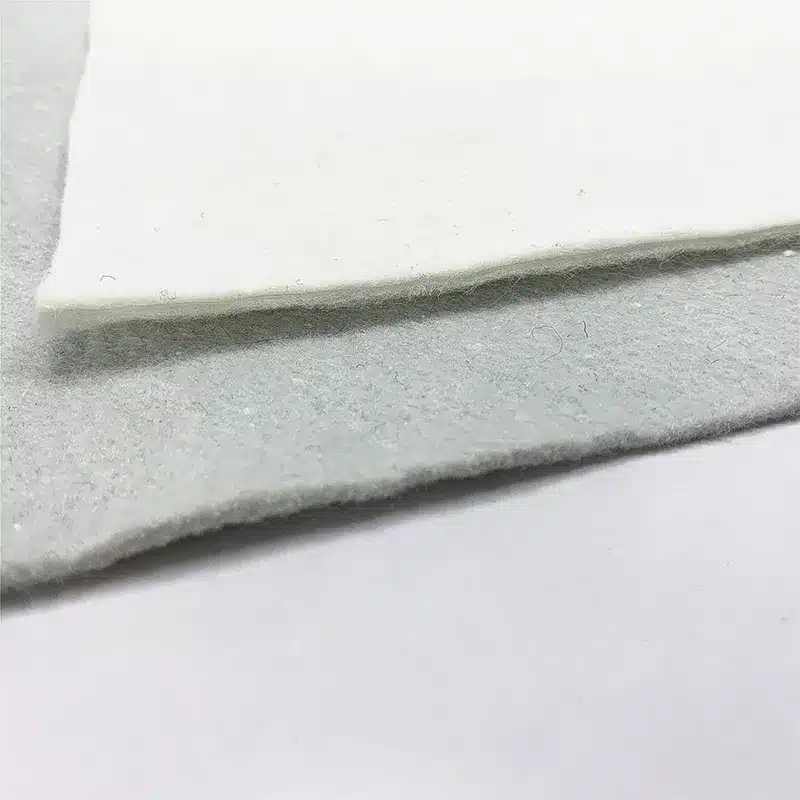

- Rango de espesor: Según el tipo (tejido o no tejido) y el gramaje, el grosor puede variar aproximadamente entre 0,1 mm y varios milímetros, adaptándose a diferentes necesidades de filtración y carga.

- Aplicaciones ligeras: Para filtración y drenaje donde se prioriza una alta permeabilidad y bajas cargas mecánicas, se utilizan geotextiles más delgados (2 oz–4 oz), ideales para zanjas drenantes, paisajismo y sistemas de drenaje superficial.

- Aplicaciones de alta exigencia: En estabilización de taludes, control de erosión, carreteras y obras con mayores cargas, se recomiendan geotextiles más gruesos (6 oz–8 oz), que ofrecen mayor resistencia a la tracción, al punzonamiento y a la degradación ambiental.

Elegir el grosor adecuado del geotextil de filtración garantiza un flujo de agua eficiente, una retención efectiva del suelo y una vida útil prolongada del sistema. La selección debe basarse siempre en las condiciones hidráulicas, el tipo de suelo, las cargas esperadas y la función específica del proyecto.

Geotextile filters are essential materials in modern engineering, providing an effective solution for soil separation, drainage, and filtration. By allowing water to pass through while preventing soil migration, geotextiles play a pivotal role in maintaining the integrity of infrastructure projects. Understanding the filter criteria, permeability, and thickness of geotextile fabric is crucial for selecting the right material for specific applications. Whether used in road construction, drainage systems, or erosion control, geotextile filters continue to prove their value in a variety of civil engineering projects.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)