+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

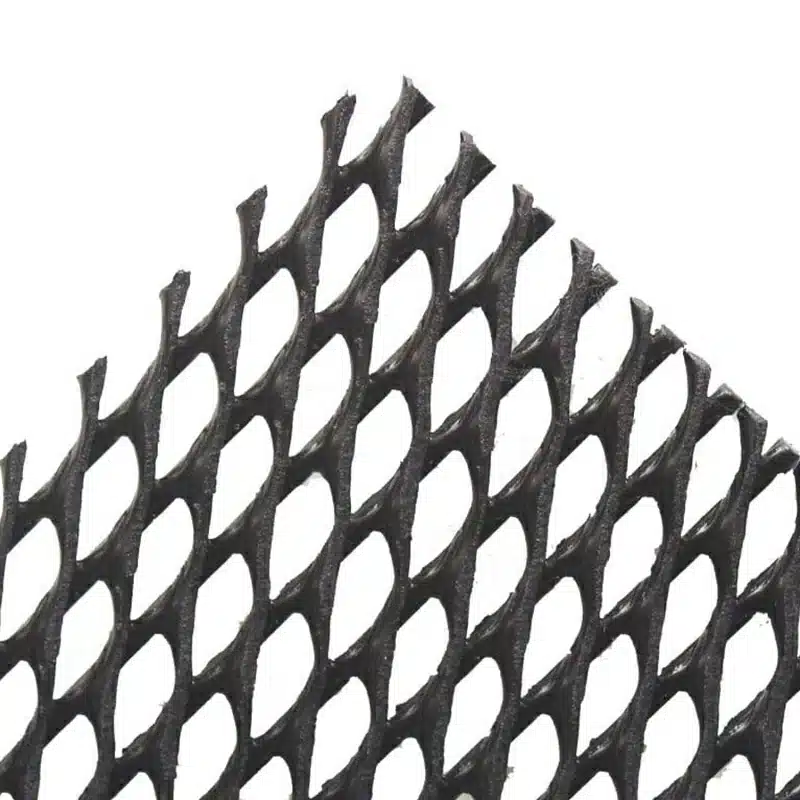

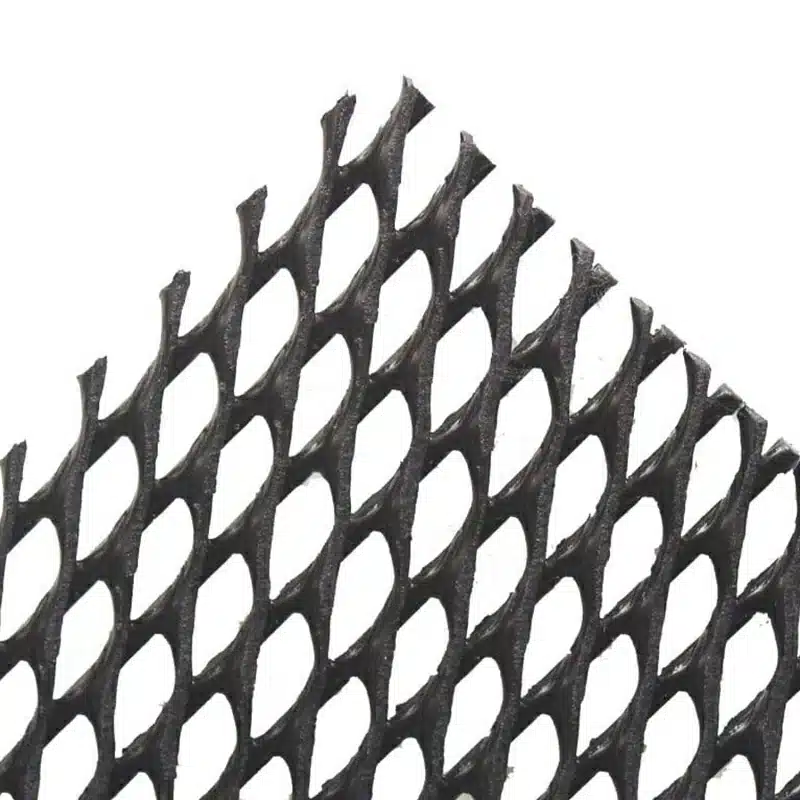

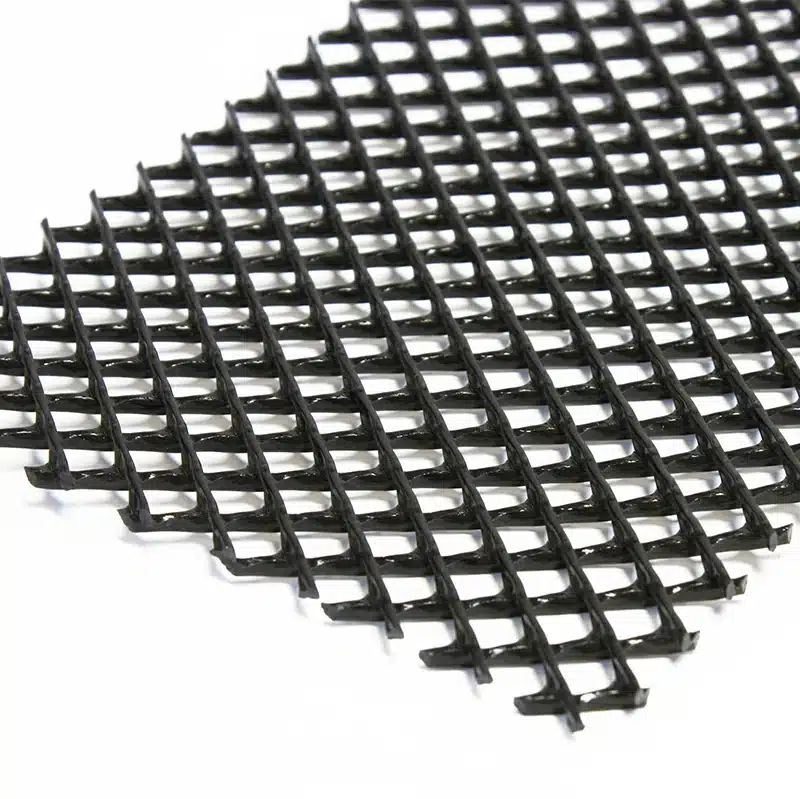

Geonet HDPE applications are gaining headlines this summer as manufacturers and engineers push toward higher‑durability, long‑lasting drainage layers in geotechnical systems. Recent innovations are reshaping industry standards and expectations.

Next-Gen Geonets Set New Standards

In May 2025, Layfield Geosynthetics introduced its next‑generation bi‑modal resin geonet—dubbed HydraNet HP—designed specifically to closely match the longevity of advanced HDPE geomembranes. Industry-standard drainage geonets have suffered from low oxidative induction times (OIT ≈ 10 min) and poor stress-crack resistance (< 1 hour), undermining overall containment system performance. The new product elevates both metrics significantly, thanks to its bi‑modal HDPE formulation that retains antioxidants and resists environmental aging.

Field Projects Showcase Proven Benefits

Meanwhile, case studies from May 2025 highlight the role of geonet HDPE in infrastructure resilience. A series of projects—including road embankment drainage, landfill leachate systems, and coastal‑erosion defenses—demonstrate its value. In soils under heavy rainfall, the material maintained effective drainage and reduced maintenance costs. Landfill applications saw faster leachate removal and regulatory compliance, while coastal stabilization efforts guarded against storm surges.

Field Deployments Prove Real-World Value

In recent months, infrastructure projects around the world have highlighted the effectiveness of geonet HDPE in challenging environments. From road construction in flood-prone zones to landfill containment systems and coastal protection initiatives, these drainage layers consistently deliver high performance. Engineers report improved water flow management, reduced erosion, and enhanced system longevity. In landfills, quicker leachate control and improved regulatory outcomes are being achieved, while coastal defenses see added resilience during extreme weather events.

What This Means for Specifiers and Engineers

Long-Term Reliability Gains

- Enhanced longevity: bi‑modal HDPE geonets support decades of drainage performance, minimizing risk of containment failure.

Versatile Infrastructure Applications

- Application diversity: field use in roads, landfills, and coastal defenses shows versatile deployment possibilities.

Future-Proof Investment Strategy

Smart investment: integrating high‑performance geonet HDPE early can reduce future maintenance and regulatory costs.

Recent advancements in geonet HDPE technology, such as the introduction of bi-modal resin-based geonets, are redefining durability and performance standards in the geosynthetics industry. Field applications in roads, landfills, and coastal defenses demonstrate their versatility and reliability, while global market trends highlight increasing demand for multifunctional and sustainable infrastructure solutions. As the industry evolves, geonet HDPE continues to play a critical role in future-ready engineering designs.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)