+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geonet and geogrid innovations are making headlines this summer as industry leaders unveil improved composite systems for infrastructure reinforcement and drainage performance.

Market Growth Fuels Innovation

According to recent market data, the global geonets market reached US $1.26 billion in 2024, projected to hit US $1.88 billion by 2030 at a CAGR of ~7% . Meanwhile, the geogrids segment registered revenues of about US $2.12 billion in 2024, with an expected growth to US $3.08 billion by 2030 (CAGR ≈ 6.4%) . These twin growth paths confirm strong demand for products that enhance soil stabilization, load distribution, and drainage.

Composite Systems for Sustainability

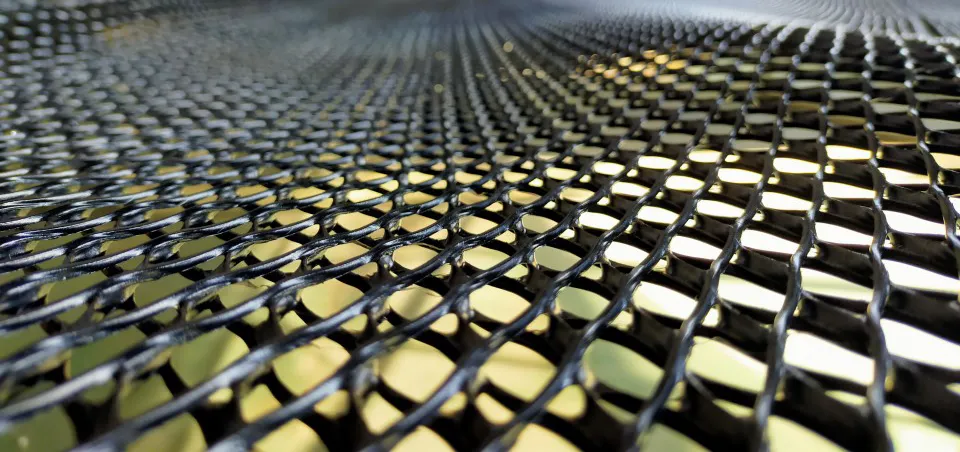

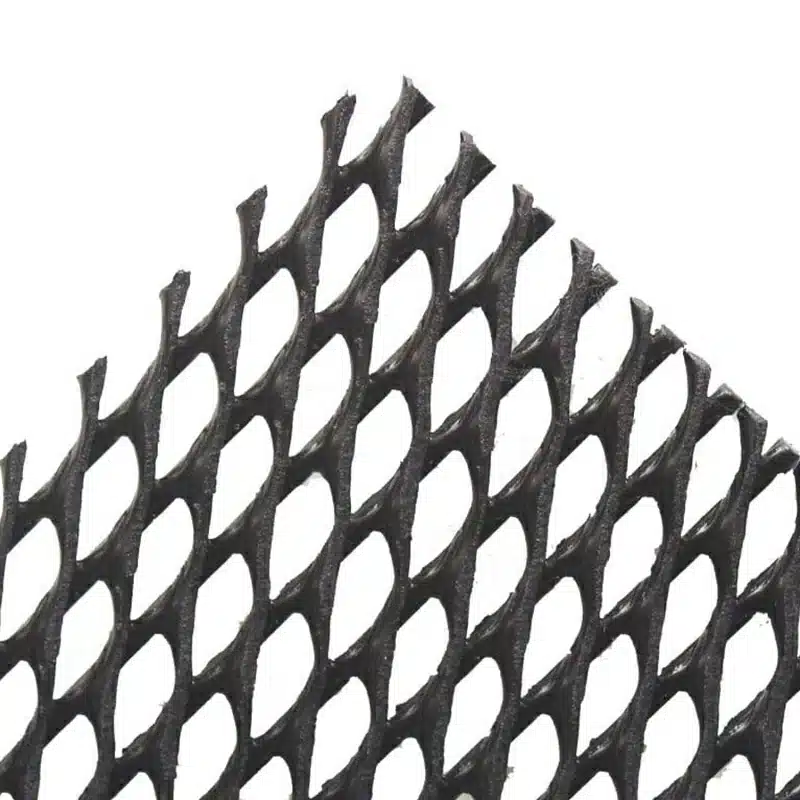

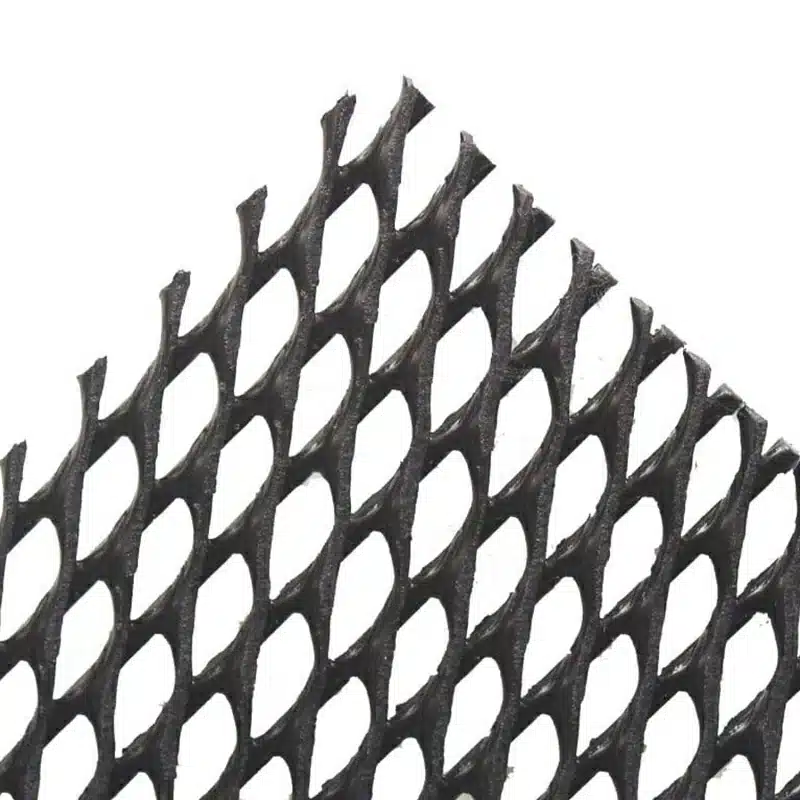

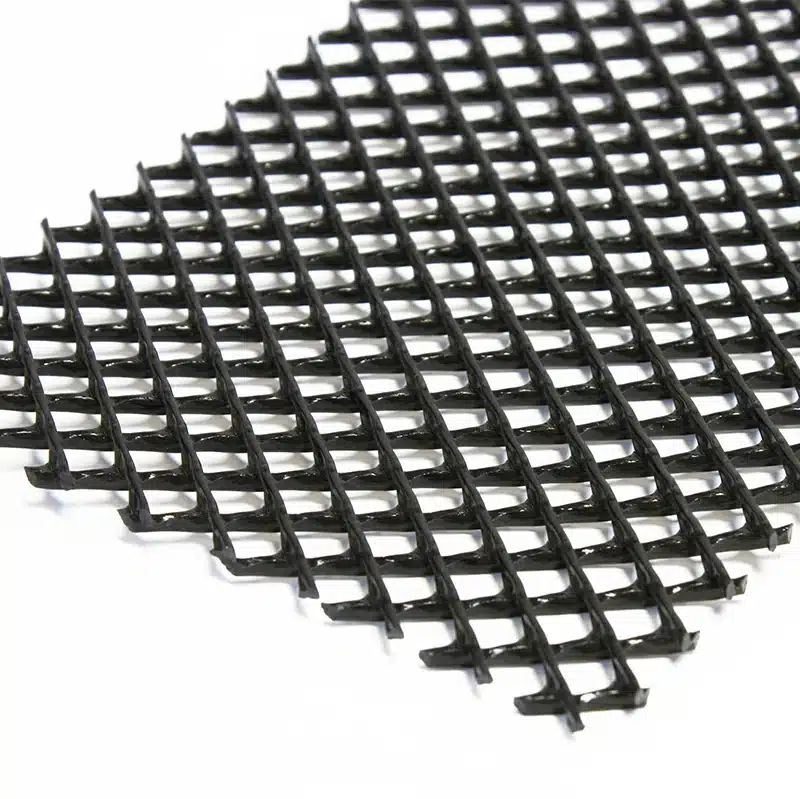

New research and field implementations in 2025 increasingly favor hybrid geosynthetic composites—especially geotextile-geonet and geomembrane-geogrid configurations—that deliver multifunctionality. These combinations offer improved separation, filtration, drainage, and reinforcement, minimizing excavation needs while boosting infrastructure resilience.

Real-World Applications Highlight Versatility

Projects across North America and Asia-Pacific are deploying systems that integrate geonet and geogrid layers for slope stabilization, landfill containment, and roadway reinforcement. In erosion‑prone zones, geogrid-reinforced slopes resist failure, while landfill projects use geonet drainage layers beneath grid structures to optimize leachate control and support heavy cover systems. Notably, erosion-control geosynthetics (like these composites) are growing fastest globally, at ~8.8% CAGR.

Implications for Engineers and Specifiers

- Design optimization: Use of geonets with geogrids allows multifunctional performance in one composite solution—saving on labor, materials, and space.

- Performance-based selection: In heavy-load or traffic applications, combining tensile reinforcement with drainage improves longevity and reduces settlement.

- Environmental advantage: These systems support sustainable, low-impact infrastructure designs by improving drainage and minimizing excavation.

By formally integrating geonet and geogrid products in composite formats, specifiers can elevate design resilience, reduce lifecycle costs, and embrace multifunctional efficiency. Let me know if you’d like case studies or technical datasheets to align with your project specifications!

Get Free Sample

We’ll respond as soon as possible(within 12 hours)