+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Understanding Composite Geotextiles: Manufacturing, Customization, and Applications

Composite Geotextile Factory: Creating Advanced Materials

Composite geotextile factories specialize in the production of complex, multi-layered materials that combine the benefits of different geosynthetic products. These factories utilize advanced manufacturing techniques to create composite geotextiles with enhanced properties, such as improved strength, durability, and filtration.

Customizing Composite Geotextiles for Specific Applications

Composite geotextiles can be customized to meet the unique requirements of various construction, engineering, and environmental projects. By altering the composition and layering of materials, composite geotextiles can be tailored to provide optimal performance in specific applications.

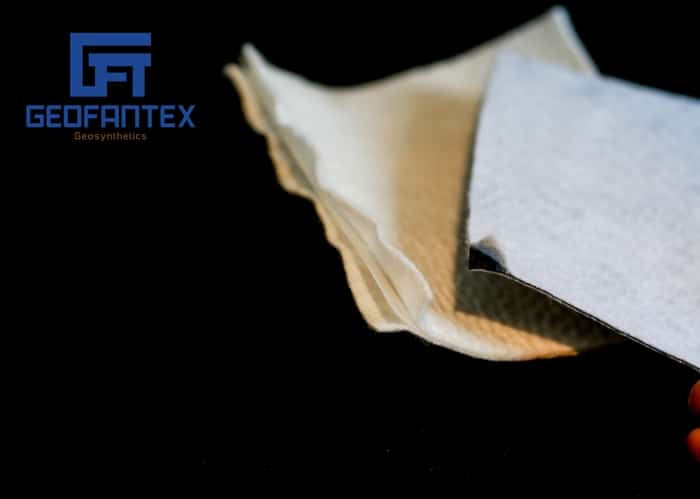

The Power of Composite Geotextile and Geomembrane

The combination of composite geotextile and geomembrane materials offers a highly effective solution for projects that require both filtration and impermeability. These materials are often used in applications such as landfill liners, pond liners, and containment systems to provide superior performance and durability.

Composite Geotextile with PE Film: Enhanced Protection

Composite geotextiles featuring polyethylene (PE) films offer improved resistance to chemicals, moisture, and UV radiation. These materials are ideal for use in projects that require additional protection from environmental factors, such as contaminated soil remediation or waste containment.

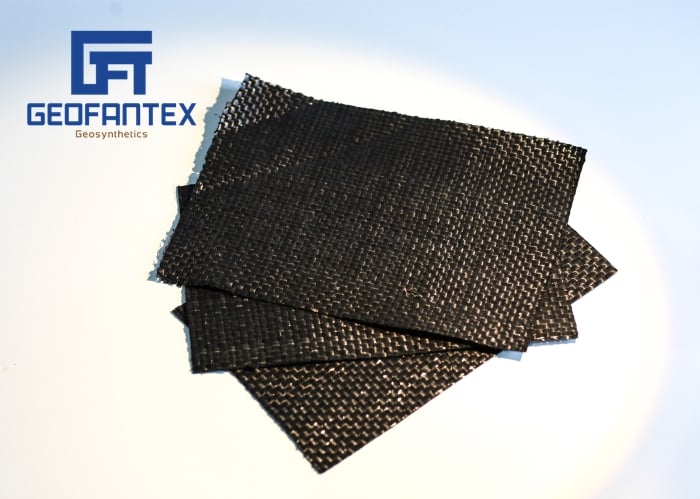

Woven Composite Geotextile: Strength and Versatility

Woven composite geotextiles are created by interlacing multiple layers of geosynthetic materials, resulting in a strong and versatile fabric. These geotextiles offer excellent reinforcement, separation, and filtration properties, making them suitable for a wide range of applications.

Supplying High-Quality Composite Geotextiles

Reliable composite geotextile suppliers offer a variety of materials to meet the diverse needs of the construction, engineering, and environmental sectors. By partnering with a trusted supplier, you can ensure the quality and performance of the composite geotextiles used in your projects.

Requesting Composite Geotextile Quotes

Obtaining composite geotextile quotes from multiple suppliers allows you to compare prices, specifications, and services. This can help you identify the best value and most suitable composite geotextile products for your specific project requirements.

Choosing the Right Composite Geotextile Supplier

Selecting a reputable composite geotextile supplier is essential for ensuring the quality and performance of your chosen materials. Look for suppliers with a proven track record, positive customer reviews, and certifications that demonstrate their commitment to quality and sustainability.

Sourcing Wholesale Composite Geotextiles

Wholesale composite geotextile suppliers offer competitive pricing and bulk discounts, making them an attractive option for large-scale projects or ongoing supply needs. By purchasing wholesale, you can reduce costs while still maintaining access to high-quality composite geotextile materials.

Composite Geosynthetic Warp-Knitting Reinforced Composite Geotextile Machine

Composite geosynthetic warp-knitting machines are used to produce reinforced composite geotextiles with increased strength and durability. These advanced machines enable the precise manufacturing of multi-layered materials, ensuring consistent quality and performance across various applications.

Applications of Composite Geotextiles in Civil Engineering

Composite geotextiles play a vital role in civil engineering projects, offering solutions for soil reinforcement, slope stabilization, and erosion control. By utilizing the unique properties of composite geotextiles, engineers can optimize project outcomes and ensure the long-term stability of structures and landscapes.

Environmental Benefits of Composite Geotextiles

Composite geotextiles contribute to sustainable construction and environmental protection by reducing soil erosion, promoting effective drainage, and containing hazardous materials. By implementing composite geotextiles in projects such as landfills, contaminated soil remediation, and stormwater management, environmental impacts can be minimized.

Research and Development in Composite Geotextiles

The ongoing research and development of composite geotextiles aim to enhance the properties and performance of these materials. Innovations in manufacturing techniques, materials science, and design contribute to the evolution of composite geotextiles and their increasing applications in various industries.

Ensuring Quality and Performance of Composite Geotextiles

To ensure the quality and performance of composite geotextiles, it is crucial to follow industry standards and guidelines during the manufacturing process. Regular testing and quality control measures help verify the properties and specifications of composite geotextiles, ensuring they meet the expectations of end-users.

Conclusion: Embracing the Potential of Composite Geotextiles

Composite geotextiles offer a range of benefits for the construction, engineering, and environmental sectors. By understanding the properties, manufacturing processes, and applications of these materials, professionals can harness their potential and make informed decisions when selecting composite geotextiles for their projects.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)