+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Product Details

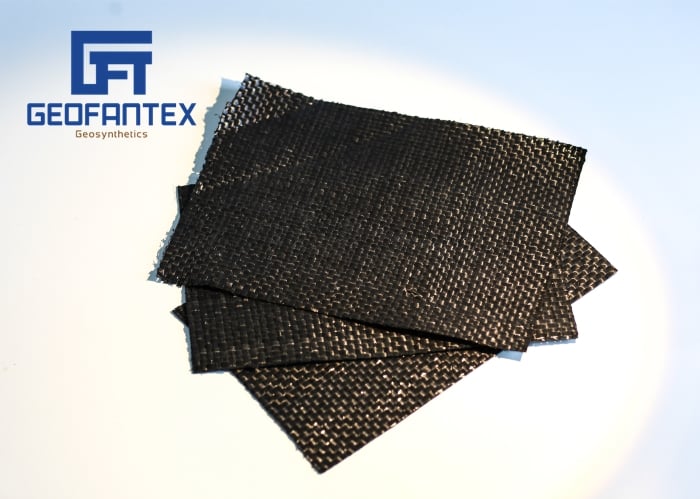

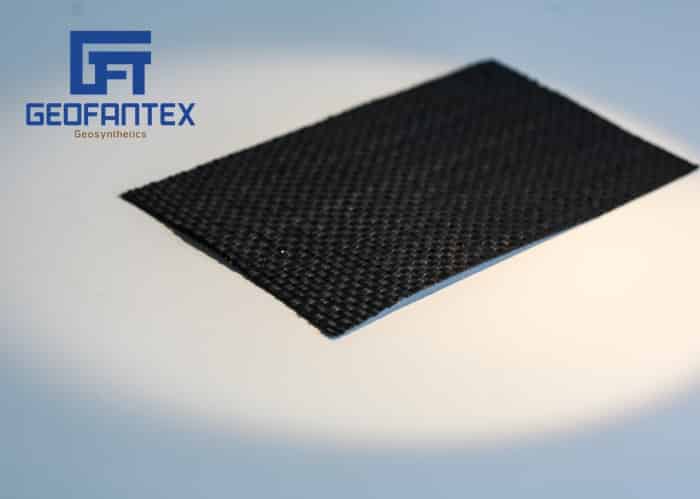

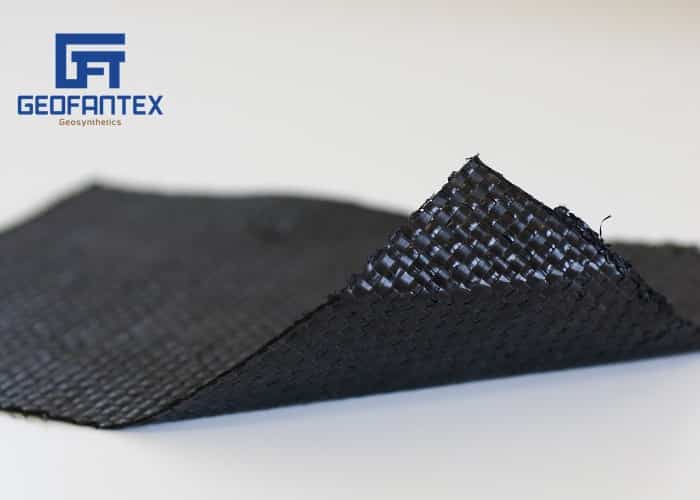

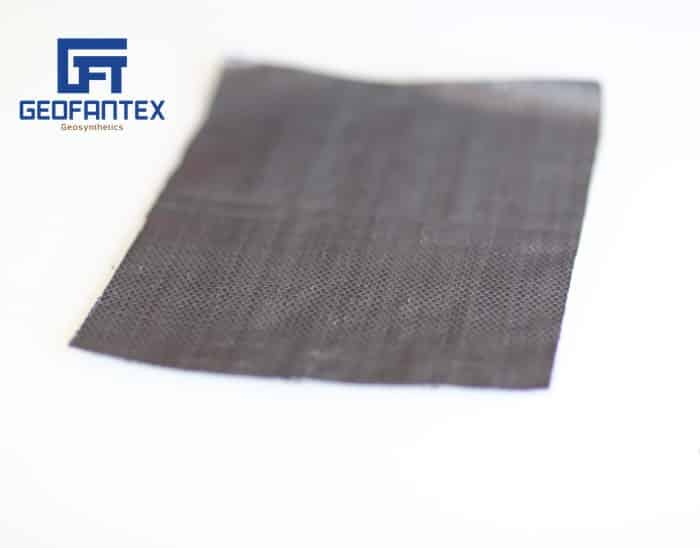

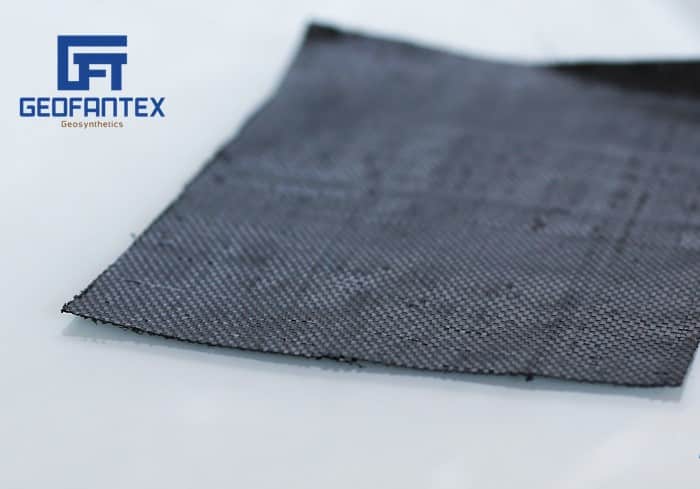

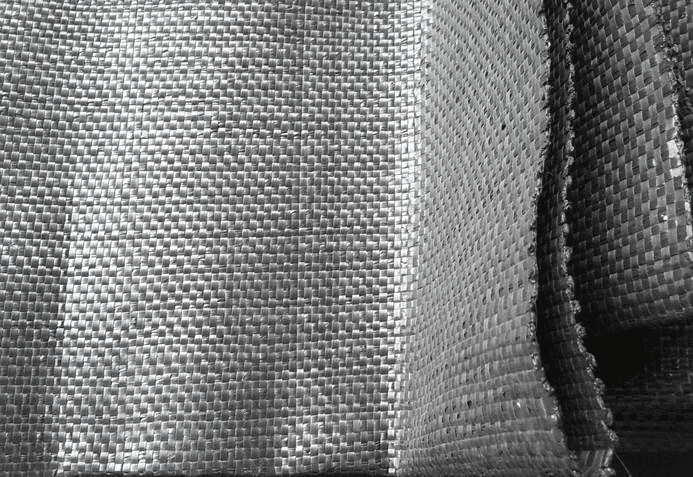

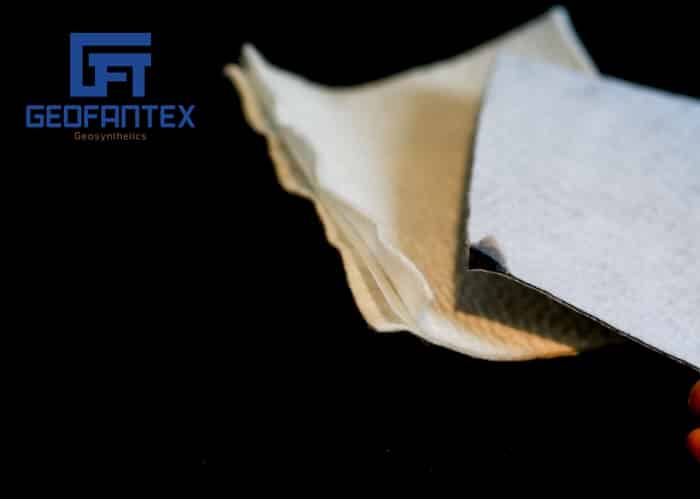

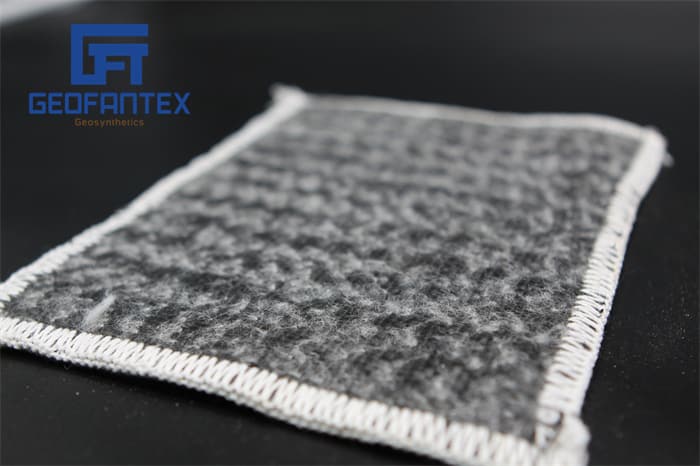

GeoFanTex® WN( PP Monofilament Woven Fabric Geotextiles) are produced from tapes (tapes-fabrics) or yarns. The fabric consists of warp yarns and weft yarns. Woven fabrics are made of polypropylene monofilament and tape yarns which provide excellent hydraulic and physical properties.

Mechanical Properties of PP Monofilament Woven Geotextile (GeoFanTex® WN)

(* GeoFanTex Geosynthetics can produce GeoFanTex® WN according to your requirements in constructions, MINIMUM ORDER QUANTITY: 20ft container)

Woven geotextile fabric has main functional mechanical properties, permeable properties, soil impermeability. Data sheet such as punch is part of mechanical properties, not full of it. Permeable properties, loading quantities or any other details will be sent to you by mail if you need them.

Woven polypropylene monofilament geotextiles (GeoFanTex® WN) are produced from tapes (tape fabrics) or yarns. A fabric consists of warp yarns and weft yarns. The fabrics are made of polypropylene monofilament and tape yarns which provide excellent hydraulic and physical properties.

The main functions of plastic tape woven geotextile:

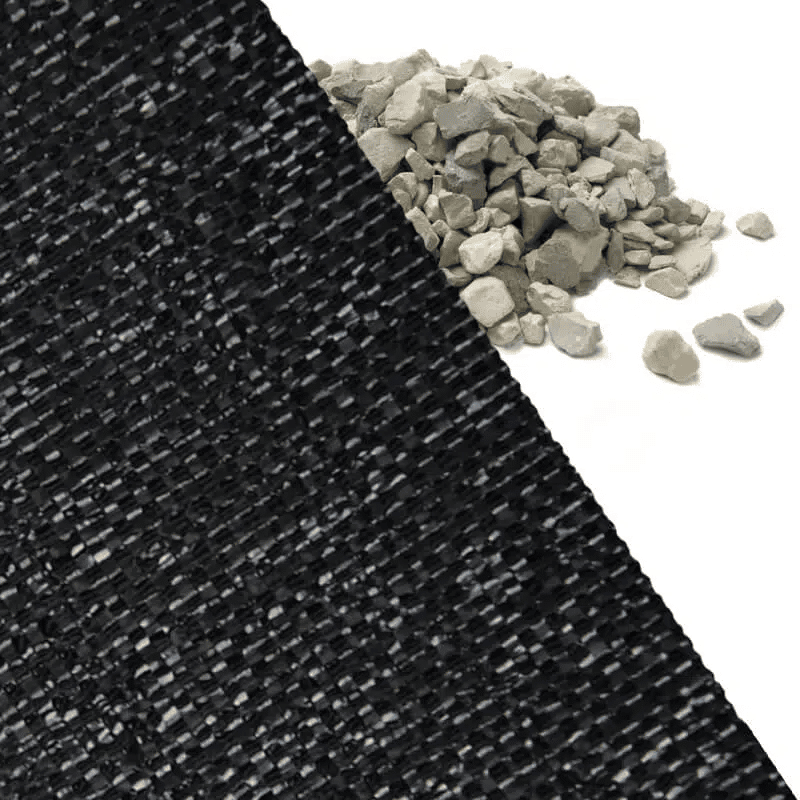

- Reinforcement woven geotextile: In order to stabilize the containment of the works that occurs during long-term use, the well can pass the stress acting locally or dispatched to the ground over a larger area

- Separation woven geotextile: Geotextiles of different geotextile material structures are separated to form a stable interface, according to the requirements and the respective characteristics play an integral role.

- Drainage and Filtration Woven Geotextile: The working cloth can allow water to pass through and block the loss of sand particles. When used for drainage, place the geotextile on the soil with poor water permeability to slowly pump the water well and move the water along the working cloth. The purpose of quickly expelling.

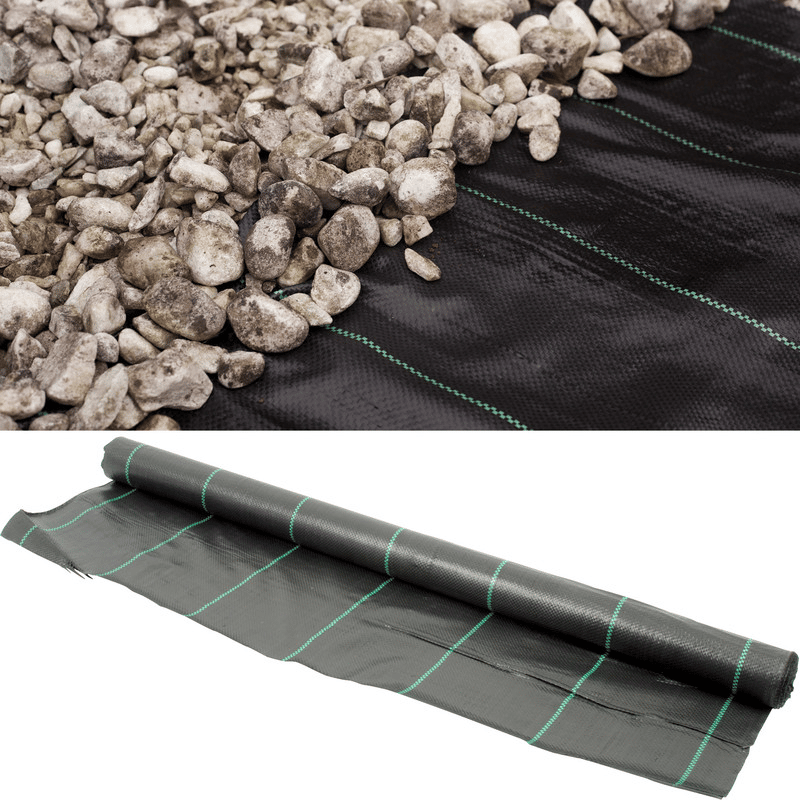

Grass companion, which can effectively suppress the growth of various weeds, has good water permeability and air permeability, makes the air in the roots have a certain fluidity, can prevent soil compaction and cause poor root growth of crops, and prevent plant roots from rotting and causing pests and diseases on the surface of the ground cloth.

Applications of woven geotextile

- Water conservancy engineering: compliance engineering of seawalls, river embankments, river banks and lake embankments; bottom protection engineering, water diversion and irrigation engineering; hazard prevention and elimination engineering and seepage reinforcement of reservoirs; reclamation engineering; flood prevention engineering.

- Highway engineering: soft base treatment; slope protection; pavement structure layer; anti-reflective seam; drainage system; green belt;

- Railway project: railway subgrade strengthening works; embankment slope reinforcement layers; waterproof tunnel lining, drainage layer; geotextile blind drainage ditch

- Airport projects: runway foundation reinforcement; base and apron pavement layer; airport road and drainage system;

- Power plant: basic engineering of nuclear power plants; thermal power plant ash dam project; Hydroelectric project.

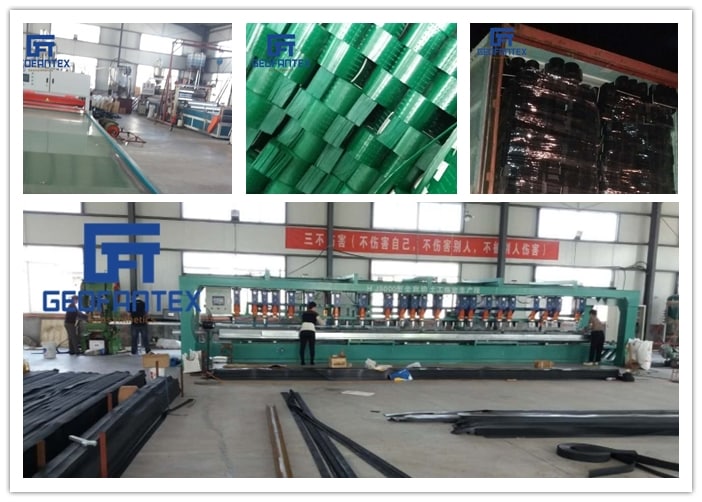

Geofantex Geosynthetics has to make a series of guarantees for our products, both for processing in plant and selling to our customers. Selling to you is the first step, service and guarantee is our task. Geofantex Geosynthetics are ISO Certified to guarantee raw material, product processing and final product. From receiving your order to replacement and installation of the products, we have solved the problems in time if you need, regardless of quality and technical guidelines or suggestions. Our company is committed to supplying high quality products with reasonable price and on-time delivery.

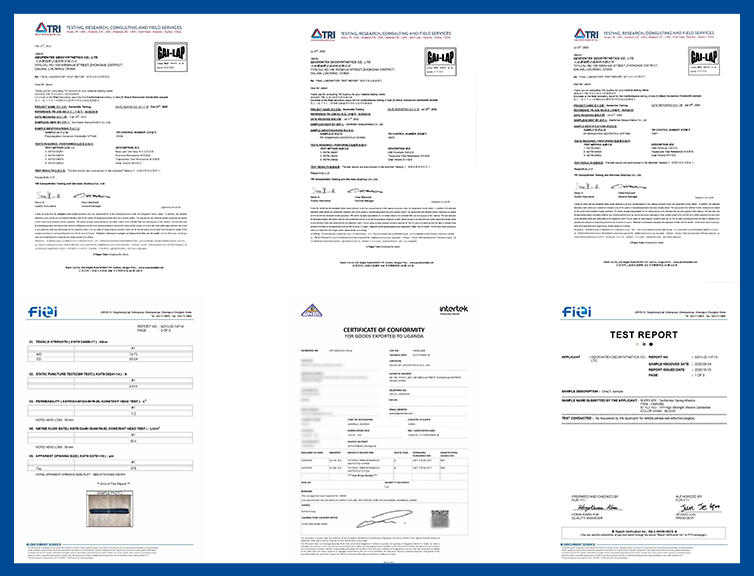

MANUFACTURING QUALITY ASSURANCE

GEOFANTEX has an on-site Manufacturing Quality Assurance Laboratory at the factory. GEOFANTEX maintains a high level of quality and up-to-the-minute results on finished products through a fully equipped, well-staffed dedicated laboratory that exists at each of the manufacturing facilities. Each facility follows the same guidelines to assess the quality of GEOANTEX products and is able to adapt to market requirements.

A. Objective

The objective of the GEOFANTEX Quality Assurance program is to define the implementation of basic Manufacturing Quality Assurance (MQA) procedures necessary to ensure consistent production of quality products supplied to the geosynthetics market. Please note that at this time, these procedures are limited to polypropylene woven geotextile.

B. Scope

In order to achieve the stated purpose of GEOFANTEX, a rigorous set of minimum standards and an effective testing program have been established to ensure compliance. These procedures and requirements are frequently reviewed and adjusted to ensure compliance with current market demands and/or predetermined project specifications. These procedures ensure that raw materials and process parameters are controlled to provide products that meet GEOFANTEX’s predefined minimum characteristics.

IDENTIFICACIÓN Y DOCUMENTACIÓN DEL PRODUCTO

A. Numeración de rollos

A cada rollo de geotextil tejido se le asigna un número de rollo único. El Laboratorio de Garantía de Calidad mantiene registros que documentan las materias primas y la información de calidad del producto resultante.

B. Procedimiento de Aprobación

Los resultados de cada rollo probado del producto se comparan con las especificaciones del cliente y el estándar de GEOANTEX 、China para verificar su cumplimiento. El Laboratorio de Garantía de Calidad aprueba aquellos materiales que cumplen estos requisitos para su envío.

C. No conformidad

El material que no cumple con los estándares mínimos de GEOFANTEX recibe un número de rollo, pero se rechaza y no se coloca en el inventario. El material se identifica como chatarra y no se utilizará. El material que cumple con los estándares mínimos de GEOFANTEX pero que no cumple con las especificaciones más estrictas del cliente no se asigna a ese cliente, sino que se coloca en el inventario como material estándar de GEOFANTEX..

D. Documentación

Se generan y suministran certificados de garantía de calidad individuales para cada rollo de producto geotextil tejido para incluir toda la información relevante de garantía de calidad sobre los materiales.

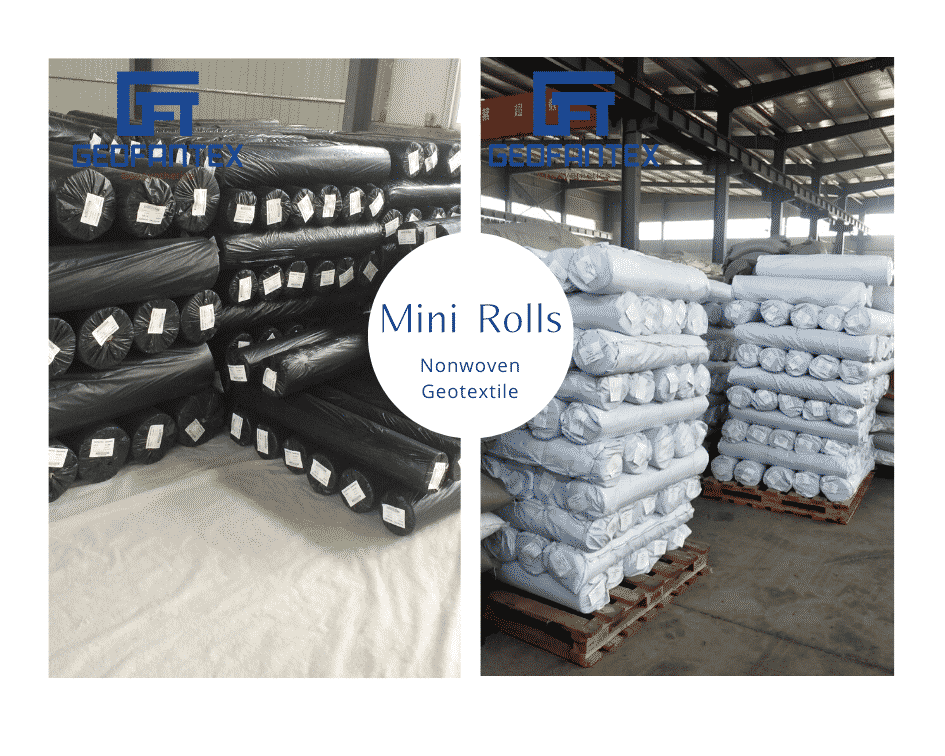

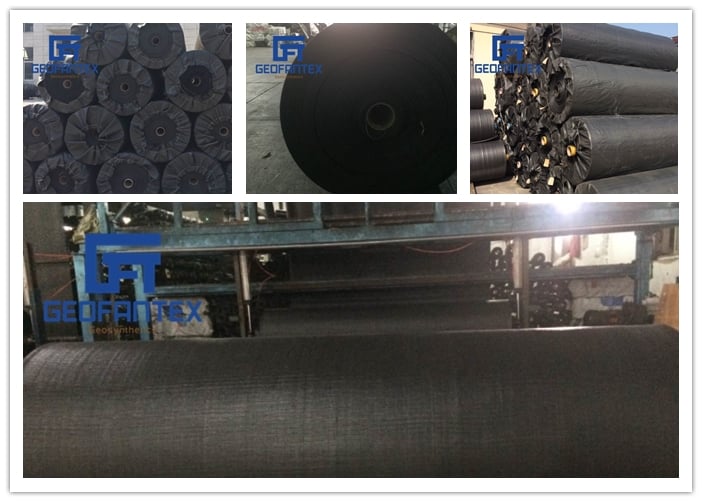

Geofantex Geosynthetics has a series of working procedures of parcel and delivery service. Geofantex Geosynthetics has supplied thousands of containers to Latin America, North America, Southeast Asia, developed countries and Africa in the past ten years. We provide the products package with the rolls, pots, bags, sheets, or your requirement in orders. Our company is committed to supplying high quality products with reasonable price and delivery on time. Delivery one 40’HQ within 7 to 10 days. And we have the obligation to increase the loading quantity and make you save the freight cost as much as possible. We supply the products by air, sea and land transportation to any region or country in the world, even door to door service.

| SEPARATION | REINFORCEMENT | FILTRATION | DRAINAGE | WATERPROOF | PREVENTION | POLLUTION PREVENTION | PROTECTION | CONSOLIDATE | |

| GEOTEXTILE | √ | √ | √ | √ | √ | √ | |||

| GEOMEMBRANE | √ | √ | √ | ||||||

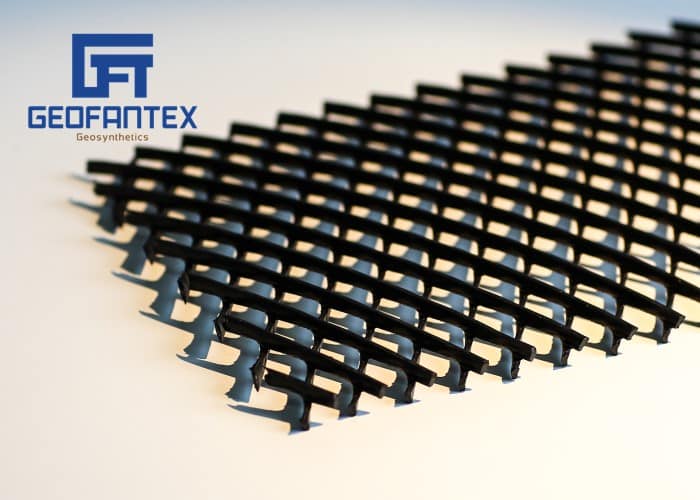

| GEOGRID | √ | √ | |||||||

| GEONET | √ | ||||||||

| GEOTUBE | √ | ||||||||

| GEOCELL | √ | √ | |||||||

| GCL | √ | √ | |||||||

| GEOCOMPOSITE | √ | √ | √ | √ | √ | √ | √ | ||

| GEOCONCRETE BLANKET | √ | √ | √ | ||||||

| Drainage Board B | √ | √ | √ | √ | |||||

| Storage and Drainage Board | √ | √ | √ | √ | |||||

| Grass Paver | √ | √ | √ | √ | √ | √ | √ | ||

| Macmat | √ | √ | √ | √ | √ | √ | √ | ||

| GeoFanTex®GD 2L | √ | √ | √ | √ | √ | √ | |||

| GeoFanPipe® FP | √ | ||||||||

| GeoFanDrain® BC | √ | √ | √ | ||||||

| GeoFanPipe® DCP | √ | √ | |||||||

| GeoFanTRM® Geomantles | √ | √ | √ | √ | √ |

General Installation Guidelines

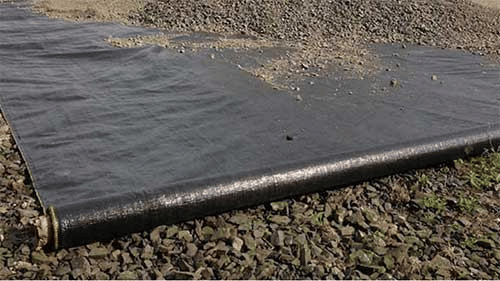

Geofantex woven geotextiles perform the functions of separation and reinforcement. They are referred to by tensile strength and offer a very high load capacity. While woven fabrics are relatively impermeable and won’t provide good drainage, their high compressive strength makes them an ideal choice for roads, parking lots, etc.

The successful use of woven geotextiles in these applications requires proper installation. The basic steps of proper installation include:

Step 1:Subgrade Preparation

Level the subgrade to remove ruts, potholes etc. with a depth greater than 100mm.

Step 2:Laying The Geotextile

Roll out the geotextile over the prepared subgrade.

Step 3:Jointing Of Geotextile Layers

Jointing is made by overlapping of rolls by at least 300mm. Increase the overlap to at least 500mm if the subgrade is uneven or soft.

Step 4:Repair Of Damages (If Necessary)

In the case of damages occurring during installation, these have to be covered with a piece of woven of the same quality. Such patches can be cut to size with a knife or with scissors.

The cover must protrude by a minimum of 500mm over the edge of the damaged spot. The patches must be fixed in their position with fill material.

Step 5:Placing Of The Sub-base Material

Trucks should not be driven directly over the geotextile: the aggregate should be back dumped. The required depth of the fill material depends on the bearing capacity of the subsoil but should not be less than 400 mm for low bearing-capacity soils.

Step 6:Spreading

Spreading should be carried out with tracked plant (due to lower pressure soil contact pressure).

Geotextile Installation Guide

If you would like further information about the installation guide, please

Certificate

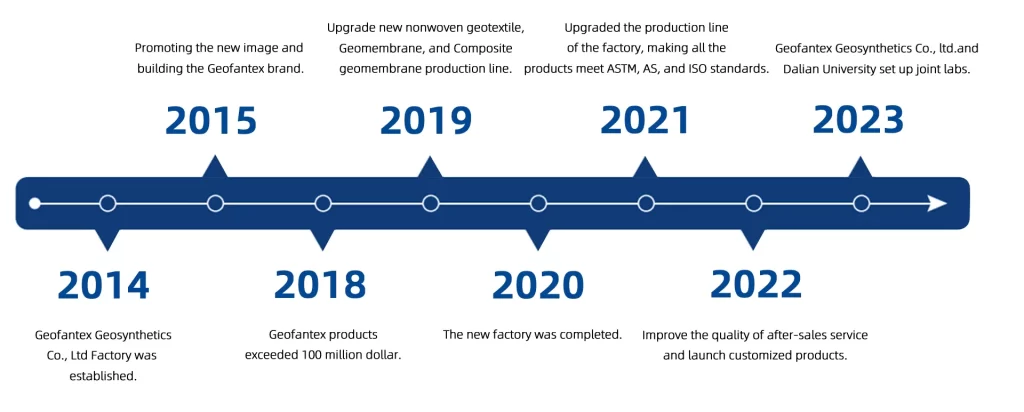

Development history of the company

Company Profile

Geofantex Geosynthetics Co., Ltd. is based in Dalian, a beautiful coastal city known for its excellent location and good transportation. Founded in 2014 with a registered capital of 5 million yuan, the company operates from an industrial park in Jinan, Shandong, covering over 50 acres. It features a modern office, advanced production equipment, and a skilled team in technical and management roles.

Geofantex has achieved ISO9001 and ISO14001 certifications and adheres to national standards to ensure product quality. Since its inception, the company has adopted advanced technologies and equipment, exporting products to regions like Australia, Canada, and Southeast Asia. Its export sales have reached significant figures, and customer feedback highlights our products’ stability, reliability, and cost-effectiveness.

The company leverages its innovative capabilities and market advantages, aiming to become a leading enterprise supported by national policies. Committed to “quality first” and “reputation first,” it emphasizes a people-oriented approach and values integrity, unity, and hard work. Geofantex seeks to collaborate with various engineering units to contribute to infrastructure development.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)