+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

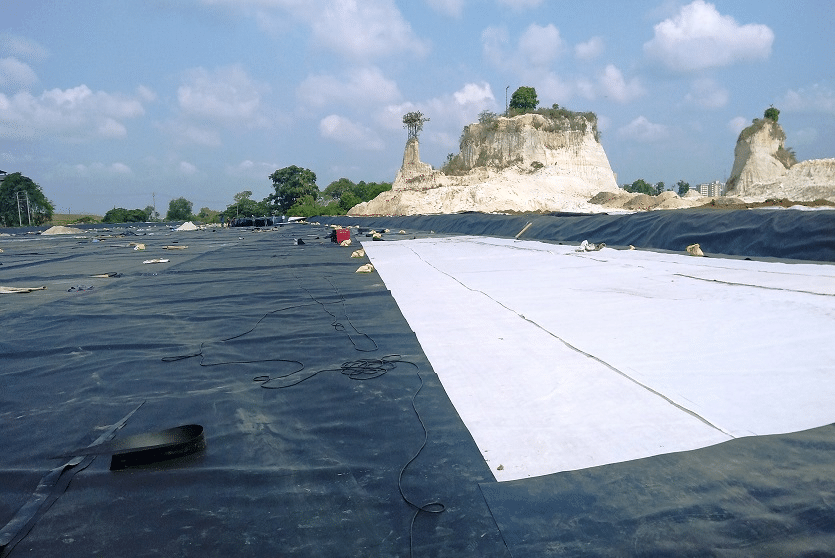

Geosynthetic Clay Liners or GCLs are constructed of two geotextiles encapsulating a layer of low-permeability sodium bentonite. As a result, they create an impermeable liner for use in landfills and ponds.

What Is Geosynthetic Clay Liner Used For?

Purpose. The primary purpose of a GCL is to serve as a hydraulic barrier, containing water, leachate, liquids, and occasionally gases. They can be employed as substitutes for compacted clay liners or geomembranes, or they can be utilized in combination with these conventional liner materials to enhance their performance.

What Are Geosynthetic Clay Liners Made Of?

Geosynthetic Clay Liners (GCLs) are constructed by integrating geotextile outer layers with a core containing sodium bentonite clay, which possesses low permeability. Bentonite, a natural sealant, undergoes hydration upon contact with water. Geosynthetic Clay Liners serve as substitutes for compacted clay liners.

What Is The Cost Of Geosynthetic Clay Liners?

(GCLs) are needle-punched reinforced composites that combine two durable geotextile outer layers with a uniform core of natural sodium bentonite clay to form a hydraulic barrier. The sodium bentonite clay utilized in Bentofix® Thermal Lock GCL is a naturally occurring clay mineral that swells as water enters between its clay platelets. When hydrated under confinement, the bentonite swells to form a low permeability clay layer with the equivalent hydraulic protection of several feet of compacted clay. Bentofix® GCLs are produced by distributing a uniform layer of sodium bentonite between two geotextiles. Fibers from the non-woven geotextile are then needle-punched through the layer of bentonite and incorporated into the other geotextile (either a woven or a non-woven). This process results in a strong mechanical bond between the fabrics. A proprietary heat-treating process – the Thermal Lock process – is then used to modify and more permanently lock the needle-punched fibers into place. Properties include increased internal shear resistance and long-term creep resistance.

How Does Geosynthetic Clay Liner Work?

Geosynthetic Clay Liners (GCLs) are composite materials that consist of geotextile outer layers encompassing a core composed of sodium bentonite clay with low permeability. Bentonite, a natural sealant, becomes activated (hydrates) when it comes into contact with water. Geosynthetic Clay Liners are employed as an alternative to compacted clay liners.

Geosynthetic clay liner is also named sodium bentonite composite waterproof pad. This is to make high-swelling sodium bentonite filling into the inside between special composite geotextile and non-woven fabric. The bentonite impermeable cushion made by the acupuncture method can form a lot of small fiber spaces. This is to make the bentonite particles can not flow in one direction. When encountering water, it can form a uniformly high-density colloidal waterproof layer in the pad, and effectively prevent water leakage. Geosynthetic clay liner is suitable for artificial lake water, landfills, underground garage, roof garden, pool, oil depot and chemicals yard.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)