+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Polypropylene geotextile is a versatile material widely used in civil engineering and construction projects for various applications. Its primary purpose is to provide reinforcement, filtration, separation, and erosion control in geotechnical and hydraulic engineering.

Polypropylene geotextile is commonly used for soil stabilization, where it improves the strength and stability of soil by distributing loads and limiting soil movement. It also acts as a filtration layer, allowing water to pass through while retaining fine particles, making it useful in drainage systems and preventing clogging. Furthermore, it serves as a separator between different soil layers or materials, preventing their mixing and maintaining the integrity of the project. Additionally, polypropylene geotextile is utilized for erosion control in areas susceptible to erosion, such as riverbanks, shorelines, and slopes, where it helps to retain soil and prevent erosion caused by water flow or wind.

What is polypropylene geotextile?

Polypropylene Geotextile: An Overview

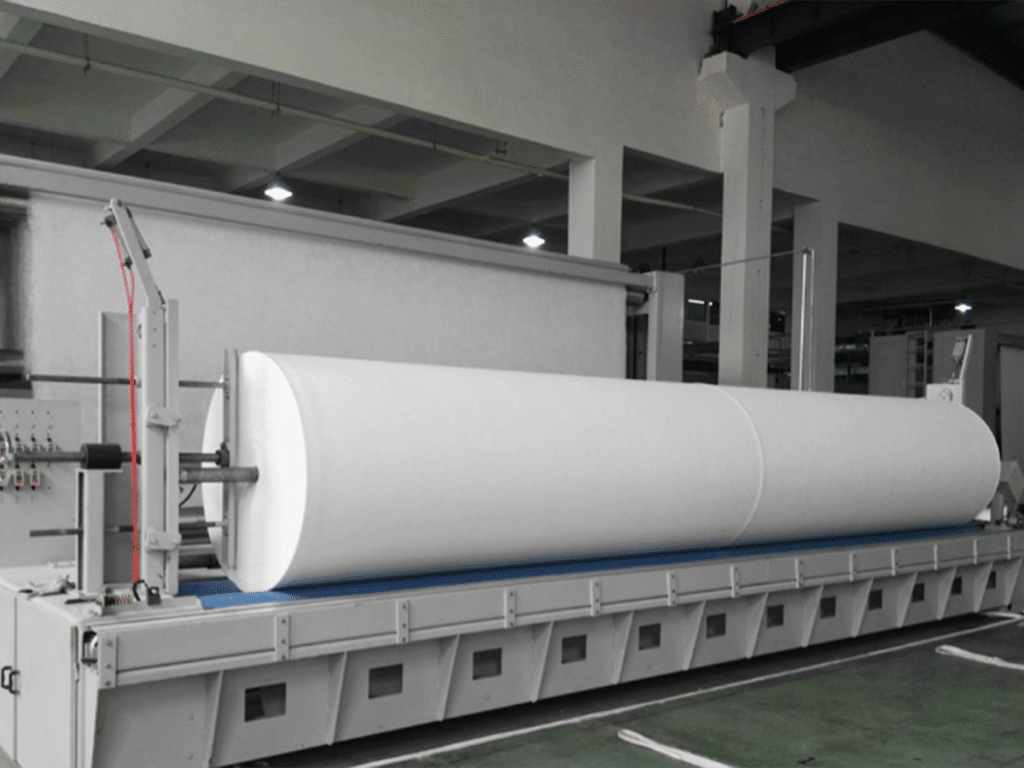

Polypropylene geotextile is a synthetic fabric used in various civil engineering, construction, and landscaping projects. Made from polypropylene, a type of thermoplastic polymer, this geotextile is designed to perform multiple functions, including separation, filtration, reinforcement, and drainage.

Key Features of Polypropylene Geotextile

- Durability: Polypropylene geotextiles are known for their excellent durability and resistance to environmental factors, such as UV radiation, chemicals, and biological degradation.

- Lightweight and Flexible: The material is lightweight and easy to handle, making it ideal for large-scale applications where ease of installation is important.

- High Tensile Strength: Polypropylene geotextiles provide significant strength, making them suitable for reinforcing soil structures and stabilizing weak soils.

- Permeability: These geotextiles allow water to pass through while filtering out fine particles, which helps in preventing soil erosion and maintaining soil stability.

Applications of Polypropylene Geotextile

- Road Construction: Used as a separator between different soil layers to prevent mixing and improve the load-bearing capacity of the road.

- Drainage Systems: Installed in drainage trenches to filter out soil particles while allowing water to flow through, preventing clogging.

- Erosion Control: Used in slopes and embankments to stabilize the soil and prevent erosion caused by water or wind.

- Retaining Walls: Employed in the construction of retaining walls to improve stability by reinforcing the soil.

Types of Polypropylene Geotextile

- Woven Polypropylene Geotextile: Made by weaving polypropylene fibers, offering high tensile strength and used primarily for soil reinforcement.

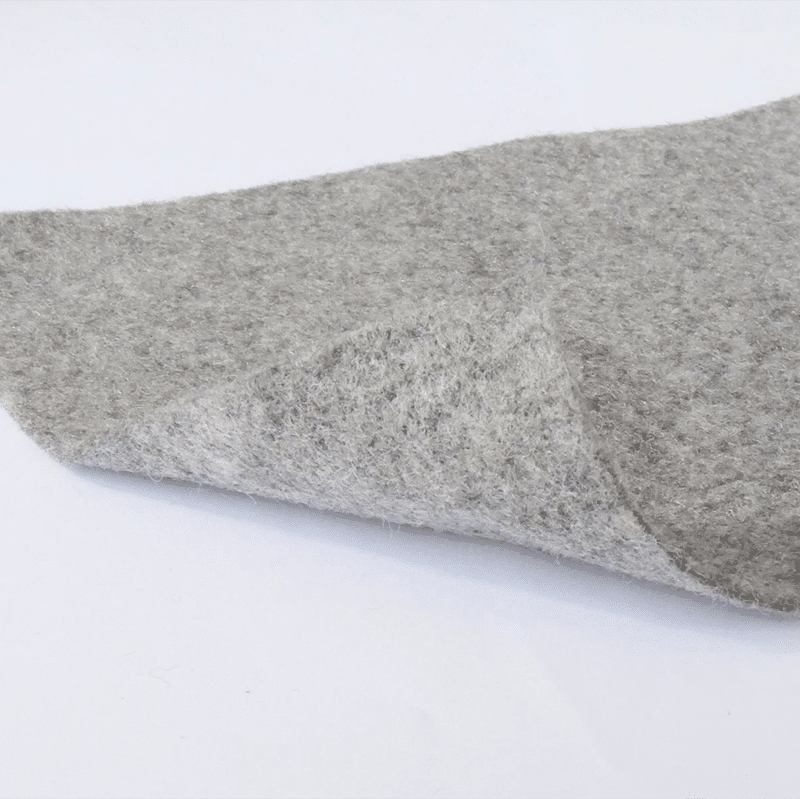

- Non-Woven Polypropylene Geotextile: Manufactured through bonding polypropylene fibers together, typically used for filtration and separation purposes.

Polypropylene geotextiles are highly versatile and are essential in various infrastructure projects, providing long-term benefits by enhancing the stability and functionality of the structures where they are applied.

Is geotextile the same as polypropylene?

No, geotextile is not the same as polypropylene, but polypropylene is one of the materials commonly used to make geotextiles.

- Geotextile is a synthetic fabric used in civil engineering and construction projects for soil stabilization, filtration, drainage, and erosion control. It can be made from various polymers, including polypropylene, polyester, and polyethylene.

- Polypropylene, on the other hand, is a type of plastic polymer, known for its strength, chemical resistance, and durability. When used to make geotextiles, polypropylene fibers are woven or non-woven into a fabric that can perform the necessary functions for the specific application.

In summary, polypropylene is a material, while geotextile is a product that can be made from polypropylene or other materials.

What is the difference between polyester and polypropylene geotextile?

Polyester and polypropylene are two common materials used in the production of geotextiles, each with distinct properties that make them suitable for different applications. Here’s a breakdown of the key differences between the two:

Material Composition:

- Polyester Geotextile:

- Made from polyethylene terephthalate (PET).

- Has a higher density and is generally heavier compared to polypropylene.

- Polypropylene Geotextile:

- Made from polypropylene (PP).

- Lighter in weight and has a lower density than polyester.

Tensile Strength:

- Polyester Geotextile:

- Known for higher tensile strength and better elongation properties.

- More resistant to stretching under load, making it suitable for applications requiring high mechanical strength.

- Polypropylene Geotextile:

- Generally has lower tensile strength compared to polyester.

- Offers good resistance to deformation but less elongation capability.

Chemical Resistance:

- Polyester Geotextile:

- Excellent resistance to most chemicals, but can degrade in high pH environments (alkaline conditions).

- Polypropylene Geotextile:

- Highly resistant to both acidic and alkaline environments, making it versatile for a wider range of soil conditions.

UV Resistance:

- Polyester Geotextile:

- Better UV resistance compared to polypropylene.

- More durable when exposed to sunlight, suitable for applications with prolonged exposure to UV radiation.

- Polypropylene Geotextile:

- Less UV resistant, which can lead to faster degradation if exposed to sunlight without protective cover.

UV Resistance:

- Polyester Geotextile:

- Absorbs more water due to its hydrophilic nature.

- May not be ideal for applications where low water absorption is critical.

- Polypropylene Geotextile:

- Hydrophobic, meaning it absorbs very little water.

- Preferred in drainage applications and situations where moisture resistance is essential.

Cost:

- Polyester Geotextile:

- Typically more expensive due to higher production costs and superior mechanical properties.

- Polypropylene Geotextile:

- Generally more cost-effective, making it a popular choice for many projects.

Environmental Impact:

- Polyester Geotextile:

- Made from PET, which is recyclable and can have a lower environmental impact if properly managed.

- Polypropylene Geotextile:

- Also recyclable, but the environmental impact depends on the specific application and end-of-life management.

Application Suitability:

- Polyester Geotextile:

- Best suited for applications requiring high tensile strength, such as road construction, reinforcement, and erosion control.

- Polypropylene Geotextile:

- Commonly used in drainage systems, soil stabilization, and filtration due to its chemical resistance and hydrophobic nature.

These differences make each material more suitable for specific types of geotextile applications, depending on the project requirements and environmental conditions.

Does geotextile fabric stop the water?

Geotextile fabric does not stop water; instead, it is designed to allow water to pass through while filtering out soil particles. The primary function of geotextile fabric, particularly non-woven types, is to facilitate drainage by permitting water to flow through the material while preventing soil from migrating. This feature is particularly useful in applications like French drains, retaining walls, and road construction, where water needs to be managed effectively to prevent erosion or structural damage.

There are specific geotextile fabrics, known as impermeable or low-permeability fabrics, that are designed to restrict water flow, but these are less common and typically used in situations where water flow needs to be controlled or blocked entirely, such as in liner systems. However, the standard geotextile fabric used in most landscaping and civil engineering applications is permeable and does not stop water.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)