+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Selecting the ideal HDPE geomembrane manufacturer is a critical decision for any construction or environmental project. In this article, we’ll explore what HDPE geomembrane is, distinguish it from other geomembranes, delve into its various types, and shed light on the manufacturing process. By the end, you’ll be well-equipped to make an informed choice.

What is HDPE Geomembrane?

Dental low-speed motor technology has seen significant advancements, improving precision and control in dental procedures. A detailed analysis is presented below.

- Recent Innovations: Newer low-speed motors incorporate technologies such as electronic speed control, pressure sensors, and feedback systems to adjust to the specific needs of each procedure. Some models feature long-lasting batteries and improved cooling systems to prevent overheating.

- Comparison to Previous Models: Unlike older models that relied on mechanical controls, modern motors allow for precise speed and torque adjustments, increasing precision in delicate procedures such as endodontics. The ability to maintain constant control over extended periods improves performance in complex treatments.

- Clinical Applications: A clear example of improvement is in endodontics, where low-speed motors with feedback help to make more precise cuts and reduce the risk of damage to surrounding tooth structures. Additionally, improvements in precision have been observed during dental cleaning and polishing treatments.

- Recommendations for Dentists: Dentists should be trained in the use of these technologies and assess the needs of their patients to choose the right model. Integrating these advanced tools can improve procedural efficiency, reduce operator fatigue, and ultimately deliver better patient outcomes.

In summary, innovations in dental low-speed motors have not only improved precision and control, but have also facilitated more effective integration of the technology into clinical practice.

What is the Difference Between Geomembrane and HDPE?

The comparison between geomembranes and high-density polyethylene (HDPE) is crucial when selecting materials for various engineering and construction applications. Below is a detailed breakdown of their differences in composition, properties, applications, and performance characteristics:

Composition

- Geomembranes: These are synthetic membranes made from various polymers, including HDPE, but they can also be constructed from materials like PVC, LDPE, and EPDM. Geomembranes are designed specifically for use in environmental engineering applications, especially for containment, lining, and barrier applications.

- HDPE (High-Density Polyethylene): HDPE is a type of polymer characterized by its high-density molecular structure. It is made from petroleum and consists of a chain of ethylene monomers. It is commonly used as one of the raw materials for geomembranes but can also be utilized independently in various applications.

Properties

- Geomembranes:

- Thickness: Typically range from 0.5mm to several millimeters, depending on the application.

- Permeability: Geomembranes are highly impermeable, providing an effective barrier against liquids, gases, and contaminants.

- Flexibility: The flexibility of geomembranes can vary depending on the type of polymer used. For example, LDPE geomembranes are more flexible than HDPE geomembranes.

- Durability: Geomembranes are designed to withstand long-term environmental exposure, such as UV radiation, temperature variations, and physical stress.

- HDPE:

- Density: HDPE has a high density and tensile strength, making it more rigid than other plastics.

- Chemical Resistance: It offers excellent resistance to chemicals, making it ideal for applications where exposure to harsh substances is a concern.

- UV Resistance: HDPE is naturally resistant to UV degradation, but in some cases, additional UV stabilizers may be added to enhance this property.

- Durability: Known for its excellent resistance to corrosion, abrasion, and impacts, HDPE is highly durable in tough conditions.

Applications

- Geomembranes:

- Lining systems: Used for landfills, reservoirs, and lagoons to prevent leakage of hazardous liquids.

- Containment barriers: Used in mining, wastewater treatment plants, and other areas requiring liquid containment.

- Environmental protection: Used in environmental engineering to prevent contamination of soil and water from industrial, municipal, or agricultural processes.

- HDPE:

- Piping systems: Widely used in the construction of water, gas, and sewage pipes due to its high strength and chemical resistance.

- Packaging: Commonly used in the production of bottles, containers, and plastic bags.

- Geomembrane Production: HDPE is often used as a primary material in the production of geomembranes due to its excellent properties for environmental containment.

Advantages and Disadvantages

- Geomembranes:

- Advantages:

- Highly impermeable to water and other liquids.

- Offers long-term durability, especially in extreme environmental conditions.

- Versatile in terms of materials, allowing for customized properties.

- Disadvantages:

- Generally more expensive compared to simple HDPE sheets.

- Installation can be complex and may require specialized techniques.

- Advantages:

- HDPE:

- Advantages:

- High tensile strength and impact resistance.

- Excellent chemical resistance.

- Cost-effective for many applications, especially in piping and construction.

- Disadvantages:

- Less flexible than some other materials, which can limit its use in applications requiring bending or shaping.

- Can degrade under prolonged UV exposure unless treated with stabilizers.

- Advantages:

Performance Characteristics

- Geomembranes:

- Durability: Extremely durable, often designed to last for decades without significant degradation.

- Permeability: Geomembranes have minimal permeability, making them ideal for applications requiring barrier properties.

- Chemical Resistance: Highly resistant to many chemicals, including acids, bases, and salts.

- HDPE:

- Durability: While HDPE is also durable, it may not be as resistant to punctures or tears as some other geomembrane materials.

- Permeability: HDPE sheets alone are also impermeable to liquids, which is why they are used to create geomembranes.

- Chemical Resistance: Offers superior chemical resistance, particularly to solvents, acids, and alkalis.

Geomembranes are a broader category of materials designed primarily for containment and environmental protection applications, whereas HDPE is a specific type of polymer that is commonly used in the production of geomembranes and other industrial products. HDPE’s durability, chemical resistance, and strength make it an ideal choice for both geomembranes and other engineering applications.

What are the Different Types of HDPE Geomembrane?

HDPE geomembranes offer versatility with options like the 30 mil HDPE liner, 40 mil HDPE liner, 60 mil HDPE liner, and 80 mil HDPE liner, each tailored for specific applications:

- Smooth HDPE Geomembrane: This type is perfect for applications where flexibility and chemical resistance are crucial.

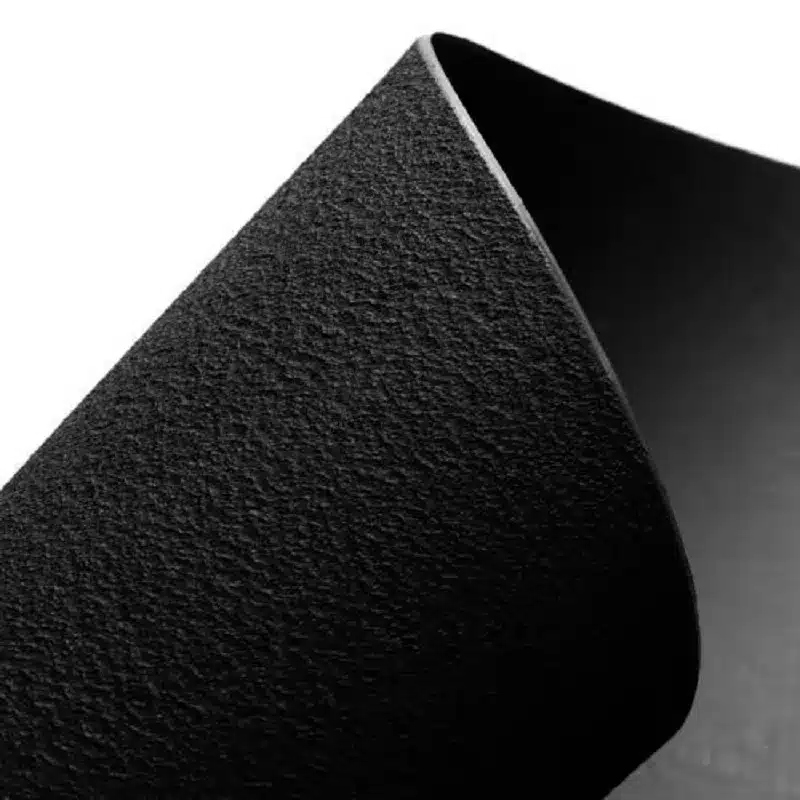

- Textured HDPE Geomembrane: It enhances friction and stability, making it ideal for use in slopes and containment scenarios.

- Stress Crack Resistant (SCR) HDPE Geomembrane: Crafted to withstand stress-induced cracking, it’s the go-to choice for challenging environments.

- Reinforced HDPE Geomembrane: Designed with added reinforcement for increased strength and puncture resistance.

What is the Manufacturing of Geomembrane?

The manufacturing process of geomembranes typically includes the following steps, involving extrusion and calendering operations:

- Polymer Selection: It all starts with selecting the appropriate polymer, like high-density polyethylene (HDPE), based on the desired geomembrane properties.

- Extrusion: The chosen polymer is melted and then extruded into a flat sheet with the desired thickness. The sheet can be smooth or textured, depending on its intended application.

- Calendering: In certain cases, the geomembrane may undergo calendering to achieve the desired thickness and surface texture.

- Quality Control: Rigorous quality control measures are implemented to ensure the geomembrane complies with industry standards for aspects like thickness, tensile strength, and other mechanical properties.

- Rolling and Packaging: Finally, the finished geomembrane is rolled onto large spools and meticulously packaged for transportation to the end user or manufacturer.

In conclusion, understanding HDPE geomembranes and their manufacturing process is essential when choosing the right manufacturer for your project. HDPE geomembranes offer excellent durability and versatility, making them a preferred choice for various containment applications in civil and environmental engineering. Whether you need a smooth, textured, or reinforced geomembrane, selecting a reputable HDPE geomembrane manufacturer is crucial for the success of your project.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)