+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geotextile road fabric, often known as geotextile, plays a crucial role in bolstering road infrastructure. This specialized fabric offers multiple advantages, such as reinforcement, soil separation, and improved drainage, ultimately extending the lifespan of roads.

Geotextiles find common application beneath both paved and unpaved roadways, including industrial haul roads, primarily for separation and stabilization purposes. Employing geotextile fabric in road construction yields numerous advantages, encompassing four critical functions: separation, stabilization, reinforcement, and filtration. Road fabrics prove particularly vital when dealing with weak subgrade soils. The industry widely recognizes the benefits, notably the long-term enhancement of pavement performance through effective separation, especially in cases with a suitable subgrade.

As evidenced by many 30-year-old roads still maintaining their structural integrity, the use of road fabric during construction has been pivotal in achieving this longevity.

What is road fabric called?

The material commonly used to provide stability and durability in road construction is known as geotextile fabric. Here is a structured breakdown of its purpose and types:

Purpose:

- Stabilization: Geotextile fabric helps in stabilizing the soil, preventing it from shifting and thus maintaining the integrity of the road.

- Reinforcement: It reinforces the road surface, enhancing its load-bearing capacity.

- Separation: This fabric separates different layers of materials, preventing them from mixing and compromising road stability.

- Drainage: It allows water to pass through while retaining soil particles, aiding in proper drainage.

Types:

- Woven Geotextile: Made by weaving fibers together, offering high tensile strength, suitable for reinforcement.

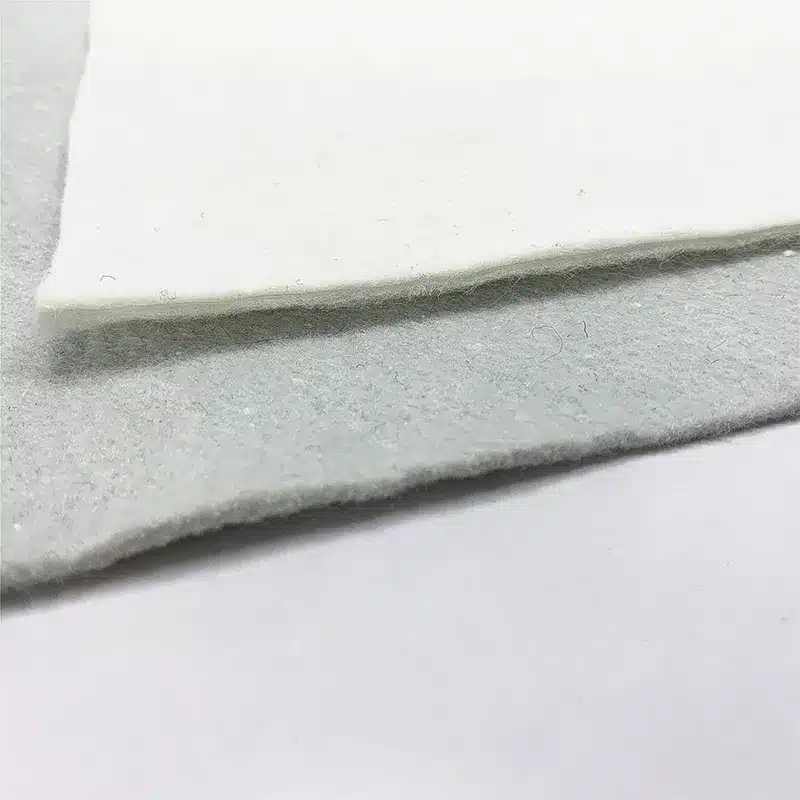

- Non-Woven Geotextile: Made from bonded fibers, often used for filtration and separation.

- Knitted Geotextile: Created by knitting fibers, providing flexibility and reinforcement.

What is road fabric for?

REFINED: Can you please explain the purpose and benefits of using road fabric in construction projects? Please answer in structured way to enhance readability.

ANSWER:

Purpose and Benefits of Using Road Fabric in Construction Projects

Introduction

Road fabric, also known as geotextile fabric, is used in various construction projects to improve the performance and longevity of roads and pavements. It is a permeable fabric that is used in combination with soil to separate, filter, reinforce, protect, or drain.

Primary Purposes

- Separation: Road fabric prevents the mixing of different soil layers, which can help maintain the integrity of the construction layers. This is crucial in preventing the base layer from being contaminated by the subgrade layer, thereby maintaining the road’s structural strength.

- Reinforcement: The fabric provides additional strength to the soil, improving its load-bearing capacity. This reinforcement is essential for supporting heavy traffic and reducing rutting.

- Filtration: It allows water to pass through while preventing soil particles from being washed away. This filtration helps manage water flow and prevents erosion.

- Drainage: The fabric facilitates the proper drainage of water, preventing water from accumulating and weakening the road structure. Effective drainage extends the lifespan of the road by reducing the risk of water-related damage.

- Protection: Road fabric helps protect other construction layers from damage during installation and use. It acts as a barrier to minimize the wear and tear caused by construction activities and traffic.

Benefits

- Increased Durability: By preventing soil mixing and providing reinforcement, road fabric enhances the overall durability and longevity of roads.

- Cost-Effective: It reduces maintenance costs by minimizing the occurrence of ruts and potholes and extending the road’s lifespan.

- Improved Performance: Roads constructed with geotextile fabrics perform better under heavy loads and adverse weather conditions.

- Environmental Protection: By managing water flow and preventing soil erosion, road fabric contributes to environmental sustainability.

Incorporating road fabric in construction projects is a strategic approach to building more durable, cost-effective, and environmentally friendly roads. Its multifunctional properties—separation, reinforcement, filtration, drainage, and protection—make it an essential component in modern road construction.

Is road fabric worth it?

Benefits of Using Road Fabric:

- Enhanced Durability: Road fabric helps reinforce the road structure, which increases its overall durability. It prevents the mixing of subgrade soil with the aggregate base, maintaining the integrity of the road layers.

- Longevity: The use of road fabric can significantly extend the lifespan of roads by providing a stable foundation, and reducing the frequency of repairs and reconstruction.

- Improved Load Distribution: Road fabric aids in distributing the load more evenly across the road surface, reducing the stress on the subgrade and preventing rutting and potholes.

- Erosion Control: It helps in controlling erosion by stabilizing the soil and preventing the loss of aggregate base material, which is crucial for areas prone to heavy rainfall and erosion.

- Cost Savings: Although the initial cost of installing road fabric may be higher, the reduction in maintenance and repair costs over time makes it a cost-effective solution.

Drawbacks of Using Road Fabric:

- Initial Cost: The upfront cost of purchasing and installing road fabric can be higher compared to traditional methods, which might be a concern for budget-constrained projects.

- Installation Complexity: Proper installation of road fabric requires skilled labor and precise techniques. Incorrect installation can negate its benefits and lead to additional costs.

- Material Compatibility: Road fabric may not be compatible with all types of soils and aggregates. Incompatibility can reduce its effectiveness and longevity.

Impact on Longevity, Durability, and Maintenance:

- Longevity: Road fabric significantly extends the lifespan of roads by preventing common issues such as potholes, rutting, and subgrade failures.

- Durability: By reinforcing the road structure and improving load distribution, road fabric enhances the overall durability of the road.

- Maintenance: Roads built with road fabric require less frequent maintenance and repairs, leading to long-term cost savings and reduced disruption to traffic.

Cost-Effectiveness:

Road fabric is considered a cost-effective solution in the long run due to its ability to reduce maintenance costs, extend the lifespan of roads, and improve overall road quality. While the initial investment is higher, the long-term benefits outweigh the upfront costs, making it a valuable addition to construction projects focused on sustainability and durability.

Should I use geotextile fabric under the gravel driveway?

Benefits of Using Geotextile Fabric Under a Gravel Driveway

- Improved Stability: Geotextile fabric helps to separate the subsoil from the gravel, preventing the gravel from mixing with the soil below. This separation maintains the integrity and strength of the gravel layer, providing a more stable surface.

- Enhanced Longevity: By preventing the intermixing of soil and gravel, the fabric helps to preserve the driveway’s structure. This leads to a longer-lasting driveway with reduced need for frequent maintenance or repairs.

- Better Drainage: Geotextile fabric allows water to pass through while keeping the soil and gravel separate. Improved drainage reduces water pooling and helps prevent erosion and potholes.

- Weed Control: The fabric acts as a barrier to weed growth, reducing the number of weeds that can grow through the gravel.

Drawbacks of Using Geotextile Fabric Under a Gravel Driveway

- Cost: The initial cost of geotextile fabric can be higher compared to not using it, especially for large driveways. However, this cost can be offset by the reduced need for maintenance over time.

- Installation Complexity: Proper installation requires careful placement and overlapping of the fabric to ensure effectiveness. Incorrect installation can lead to issues such as fabric movement and exposure, reducing its benefits.

- Potential for Fabric Damage: Heavy traffic or sharp objects can damage the fabric over time. Damaged fabric may lead to reduced effectiveness and the need for repairs or replacement.

Impact on Stability, Longevity, and Maintenance

- Stability: Geotextile fabric enhances stability by preventing soil and gravel intermixing, leading to a more solid and reliable driveway.

- Longevity: The separation of materials and improved drainage contribute to a longer-lasting driveway with fewer issues.

- Maintenance: With better stability and longevity, the need for maintenance is reduced. Weed growth is also minimized, making upkeep easier.

Suitability Factors

- Soil Conditions: In areas with poor soil conditions (e.g., clay or sandy soil), geotextile fabric is particularly beneficial as it improves stability and prevents soil erosion.

- Climate: In regions with heavy rainfall, the fabric’s drainage capabilities are advantageous. Conversely, in arid areas, the need for drainage may be less critical.

- Traffic Load: Driveways that will experience heavy traffic or are used by large vehicles may benefit more from the added stability provided by geotextile fabric.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)