+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

In recent years, the construction and civil engineering industries have increasingly turned to innovative solutions to address complex challenges in soil stabilization and reinforcement. Among these, geocell technology has emerged as a key player, offering versatile, durable, and environmentally friendly solutions. This article delves into the essence of geocell soil stabilization, exploring its purpose, mechanisms, and applications, particularly in slope stabilization and soil reinforcement, to provide a comprehensive understanding of this cutting-edge technology.

What is the purpose of Geocell?

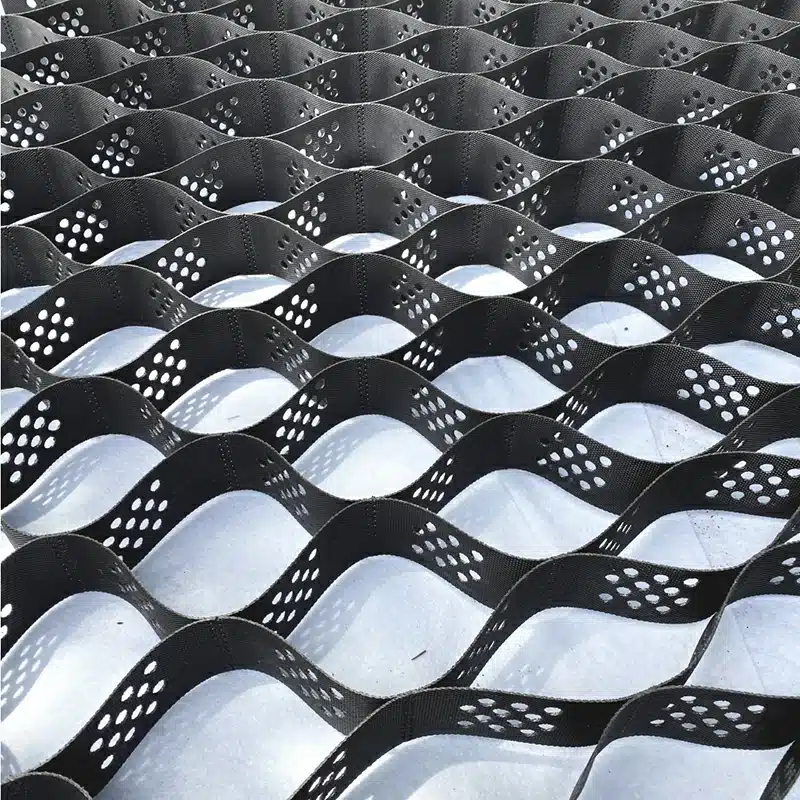

Geocells are engineered for the primary purpose of improving the load-bearing capacity of soils, while also serving to protect slopes from erosion and help stabilize the surface, thereby maintaining the integrity of civil engineering structures. They are three-dimensional, honeycomb-like structures made from high-density polyethylene (HDPE) or other polymer materials. When filled with soil, sand, or gravel, geocells create a stable and rigid framework that increases the strength and stiffness of the base materials. This dual functionality of geocells is particularly beneficial in areas with weak soils, where traditional construction methods might fail or prove to be economically unfeasible.

What are geocells in slope stabilization?

In the context of slope stabilization, geocells are employed to protect slopes from erosion and assist in stabilizing the surface. Acting as a containment system, they prevent soil erosion and slippage. When applied to slopes, geocells enhance the shear strength of the soil, effectively reducing the risk of landslides and soil movement. They are laid out on the slope surface and anchored securely; then, filled with soil or other granular materials. The interlocking cells work together to distribute weight evenly, absorb and mitigate the forces of gravity, and maintain slope stability under various environmental conditions.

What is the mechanism of Geocell?

The mechanism of geocell technology revolves around confinement and reinforcement, leveraging the confinement effect from the geocell walls, flexural capacity, and tension membrane action of the geocell layer. The three-dimensional cells confine the infill material, which significantly enhances its load-bearing capacity by distributing loads over a wider area. This confinement effect prevents lateral movement of the soil and reduces vertical settlement. Furthermore, the interconnected cells provide tensile reinforcement to the soil, bolstered by the flexural capacity and tension membrane action, improving its overall stability. This comprehensive mechanism of confinement and reinforcement is what makes geocell technology highly effective for soil stabilization projects.

What are the applications of geocells for soil reinforcement?

Geocells have a wide range of applications in soil reinforcement, prominently in the construction of roads and embankments, including railway embankments, airport runways, and retaining walls. They are also employed in landscaping and agricultural projects to prevent soil erosion and in the construction of water channels and embankments for flood control. In the construction of roads, for example, geocells increase the strength and durability of the road base, enabling it to withstand heavy traffic loads and adverse weather conditions. Similarly, in agricultural practices, they help to conserve soil and water, promoting sustainable land management practices.

Geocell technology represents a significant advancement in the field of civil engineering, offering a sustainable, cost-effective, and versatile solution for soil stabilization and reinforcement. Its application in slope stabilization, road construction, and other areas highlights its adaptability to various environmental and structural challenges. By understanding the purpose, mechanism, and applications of geocells, professionals in the construction and engineering sectors can leverage this technology to enhance the durability, safety, and longevity of their projects.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)