+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

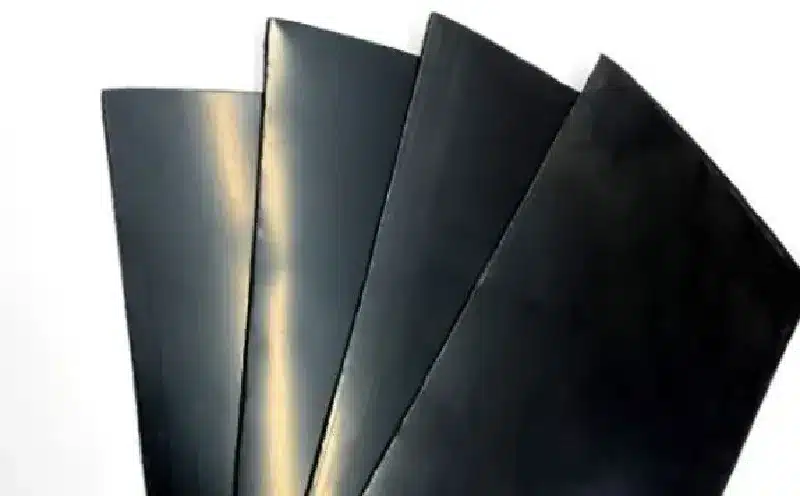

In today’s environmentally conscious world, the protection of natural resources and the containment of hazardous materials have never been more important. One of the key players in this endeavor is the HDPE geomembrane liner, a product that has revolutionized the way industries and environmental management systems safeguard the Earth’s precious assets. This guide will delve into the essence of HDPE geomembrane liners, exploring what they are, their materials, their differences from other liners, and their critical roles in environmental protection.

What is geomembrane lining?

A geomembrane lining is a synthetic membrane or barrier used primarily for the containment of liquids, solids, and gases. Made from impermeable materials such as high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC), and other polymeric materials, geomembrane linings are essential components in a variety of environmental, geotechnical, hydraulic, and transportation applications. Here’s a detailed overview:

Key Functions

- Containment: They prevent the leakage of hazardous materials, protecting soil and groundwater from contamination.

- Separation: Geomembranes can act as barriers to separate different materials or waste layers.

- Protection: They provide a protective layer to prevent chemical erosion or physical damage to underlying or surrounding structures.

Common Applications

- Landfills: Used as liners for waste containment to prevent leachate migration into the ground.

- Mining: Employed in heap leach pads, tailings ponds, and containment systems for mining operations.

- Water Containment: Used in ponds, reservoirs, canals, and other water storage facilities to prevent water loss.

- Wastewater Treatment: Applied in lagoons and treatment plants to contain and manage wastewater.

- Environmental Protection: Used in bioreactors, secondary containment systems, and for capping contaminated sites.

Types of Geomembrane Linings

- LDPE (Low-Density Polyethylene): More flexible than HDPE. Used in applications requiring adaptability to complex shapes and surfaces.

- PVC (Polyvinyl Chloride): Flexible and easy to install. Suitable for applications with less exposure to harsh chemicals.

- LLDPE (Linear Low-Density Polyethylene): Combines the flexibility of LDPE with the strength of HDPE. Used in containment and capping applications.

- EPDM (Ethylene Propylene Diene Monomer): Highly flexible and durable. Suitable for ponds, canals, and reservoirs.

Installation and Quality Control

- Welding: Seams are often welded together using hot wedge or extrusion welding techniques to ensure impermeability.

- Testing: Various testing methods, such as vacuum testing, air pressure testing, and destructive testing, are employed to verify seam integrity.

- Preparation: Proper surface preparation, including smoothing and compacting the substrate, is critical for effective installation.

- Monitoring: Post-installation monitoring ensures long-term performance and leak detection.

Benefits

- Environmental Protection: Geomembranes provide a critical barrier against contamination, protecting ecosystems and human health.

- Cost-Effectiveness: They offer an economical solution for containment needs compared to traditional methods.

- Durability: High resistance to weathering, chemical exposure, and mechanical damage.

Challenges

- Installation Complexity: Requires skilled labor and proper equipment to ensure effective installation.

- Material Selection: Choosing the right material based on the specific application and environmental conditions is crucial.

- Long-Term Performance: Regular maintenance and monitoring are necessary to ensure long-term integrity and functionality.

Geomembrane linings are vital components in modern engineering and environmental protection, offering reliable and effective solutions for containment and barrier needs across various industries.

What is HDPE geomembrane material?

HDPE (High-Density Polyethylene) geomembrane is a type of synthetic material widely used in various civil engineering and environmental applications. Here’s a detailed overview:

Properties of HDPE Geomembrane:

- Material Composition: HDPE geomembranes are made from high-density polyethylene, a thermoplastic polymer known for its high strength-to-density ratio.

- Durability: This material is highly resistant to punctures, tears, and chemicals, making it ideal for long-term use.

- Impermeability: HDPE geomembranes provide excellent impermeability, preventing the passage of liquids and gases.

- Flexibility: Despite its strength, HDPE is flexible enough to conform to various surfaces and shapes.

- Temperature Resistance: HDPE geomembranes can withstand a wide range of temperatures, maintaining their integrity in extreme hot and cold conditions.

- UV Resistance: They have good resistance to UV radiation, although prolonged exposure to direct sunlight may still require protective measures to maintain longevity.

Applications:

- Landfills: Used as liners and covers to contain waste and prevent leachate from contaminating groundwater.

- Water Containment: Ideal for lining reservoirs, ponds, and canals to prevent water loss.

- Mining: Utilized in heap leach pads, tailings dams, and containment systems to control and manage mining byproducts.

- Agriculture: Used in irrigation ponds, water storage, and as barriers in agricultural applications.

- Environmental Protection: Employed in projects requiring containment of hazardous materials, such as in spill containment systems.

Installation:

- Site Preparation: The surface must be properly graded and free from sharp objects that could puncture the geomembrane.

- Unrolling: The geomembrane rolls are unrolled over the prepared surface.

- Seaming: Adjacent sheets are welded together using techniques such as thermal fusion to create a continuous barrier.

- Anchoring: The edges of the geomembrane are secured to prevent movement and ensure stability.

Advantages:

- High Chemical Resistance: Suitable for environments with aggressive chemicals.

- Longevity: Long lifespan due to resistance to degradation.

- Cost-Effective: Efficient in terms of both material and installation costs.

- Versatility: Can be used in a wide range of applications and conditions.

Considerations:

- Proper Installation: Requires skilled labor and specialized equipment for proper installation and seaming.

- Quality Control: Regular inspections and testing are essential to ensure the integrity of the geomembrane.

- Environmental Impact: Must be disposed of properly to prevent environmental contamination at the end of its lifecycle.

In summary, HDPE geomembranes are versatile and durable materials crucial for various applications requiring containment and protection against contamination.

What is the difference between an HDPE liner and a geomembrane?

Materials

- HDPE Liner: Made from High-Density Polyethylene (HDPE), a thermoplastic polymer known for its high strength-to-density ratio.

- Geomembrane: Can be made from various materials including HDPE, Linear Low-Density Polyethylene (LLDPE), Polyvinyl Chloride (PVC), and others.

Properties

- HDPE Liner: Highly resistant to chemicals and UV radiation. Excellent puncture resistance and tensile strength. Has a relatively low flexibility compared to some other materials.

- Geomembrane: Properties vary depending on the material used. Generally, geomembranes are designed to be impermeable to fluids. It can have varying degrees of flexibility, durability, and chemical resistance.

Applications

- HDPE Liner: Used in applications requiring robust chemical and UV resistance, such as landfills, mining operations, and water containment.

- Geomembrane: Used in a wide range of applications including pond liners, wastewater treatment, environmental containment, and as barriers in landfill projects.

Advantages and Disadvantages

- HDPE Liner:

- Advantages: High durability, excellent chemical and UV resistance, cost-effective for large projects.

- Disadvantages: Less flexible than some other materials, making installation more challenging in complex areas.

- Geomembrane:

- Advantages: Versatile, can be tailored to specific project needs based on material choice, varying degrees of flexibility and strength.

- Disadvantages: Performance varies greatly depending on the material, which may not always offer the same level of chemical or UV resistance as HDPE.

HDPE liners are a type of geomembrane specifically made from HDPE material, known for its robustness and chemical resistance. Geomembranes, on the other hand, encompass a broader category of liners made from various materials, each offering different properties and suited for different applications.

What is the purpose of the geomembrane liner?

The geomembrane liner is a critical component used in various applications to provide an impermeable barrier for liquids and gases. Here are its primary purposes and benefits:

Containment:

- Environmental Protection: Geomembrane liners are used in landfills to contain hazardous materials and prevent contamination of soil and groundwater.

- Water Storage: They are used in reservoirs, ponds, and irrigation canals to prevent water loss through seepage.

Leak Prevention:

- Industrial Applications: In mining, geomembrane liners prevent the leakage of chemicals and waste materials into the environment.

- Oil and Gas: Used in the lining of storage tanks and containment areas to prevent oil spills and leaks.

Durability and Longevity:

- Material Strength: Made from robust materials like high-density polyethylene (HDPE), they are resistant to punctures, UV degradation, and chemical exposure.

- Long Lifespan: Geomembrane liners have a long service life, making them cost-effective over time.

Versatility:

- Wide Range of Applications: Suitable for use in agriculture, aquaculture, wastewater treatment, and more.

- Adaptability: Can be custom-fitted to various shapes and sizes, accommodating different project needs.

Regulatory Compliance:

- Environmental Regulations: Helps industries comply with environmental protection laws by preventing pollution and ensuring safe waste management practices.

HDPE geomembrane liners stand at the forefront of environmental protection technology, offering a robust, efficient, and cost-effective solution to the challenges of contamination and water conservation. Understanding the significance of these liners, their material specifics, and their applications highlights their indispensable role in safeguarding our natural resources. As we move forward, the continued innovation and application of HDPE geomembrane liners will be pivotal in our collective effort to protect the environment for future generations.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)