+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

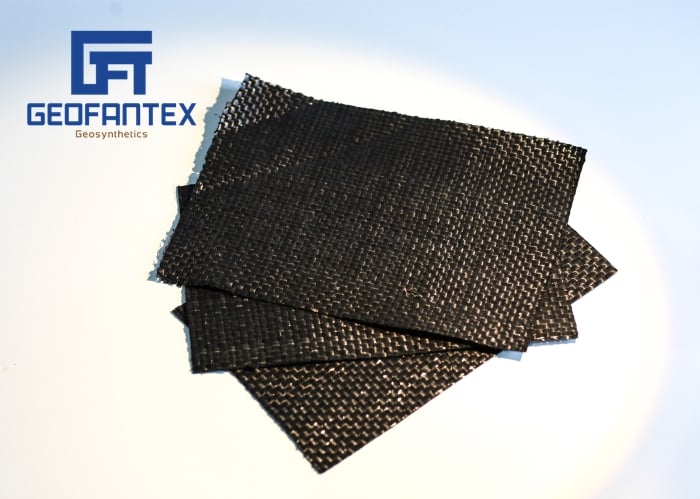

There are two kinds of fiberglass geogrids commonly used now, with self-adhesive and without self-adhesive. Those with self-adhesive can be laid directly on the flat base, and those without self-adhesive are usually fixed with nails.

- Construction site: It is required to be compacted and leveled, and the sharp protrusions should be removed.

- Grid laying: On a flat and compacted site, the main force direction (longitudinal) of the grid installed and laid should be perpendicular to the axis of the embankment, and the laying should be flat, without wrinkles, and as tight as possible. Fix it with nails and earth-rock weight. The main force direction of the laid grid is preferably full-length without joints. The connection between the webs can be manually tied and lapped, and the lap width is not less than 10cm. If there are more than two layers of grilles, the layers should be staggered. After laying a large area, the flatness should be adjusted as a whole. After filling a layer of soil and before rolling, the grid should be tensioned again manually or with machines, and the force should be uniform so that the grid is in a state of tension and stress in the soil.

- Filling selection: Filling should be selected according to design requirements. The practice has proved that it can be used as filler except for frozen soil, swamp soil, household garbage, chalk, and diatomaceous earth. However, gravel soil and sandy soil have stable mechanical properties and are less affected by water content, so they should be preferred. The particle size of the filler shall not be greater than 15cm, and attention shall be paid to controlling the gradation of the filler to ensure the compacted weight.

- Paving and compacting of filler: After the grid is laid in place, it should be covered with soil in time, and the exposure time should not exceed 48 hours. The flow method of backfilling while laying can also be adopted. Spread the filler at both ends first, fix the grid, and then push it to the middle. The order of rolling is first on both sides and then in the middle. During rolling, the pressure wheel cannot directly contact the reinforcement, and the uncompacted reinforcement generally does not allow vehicles to drive on it, so as to avoid the dislocation of the reinforcement. Layer compaction is 20-30cm. The degree of compaction must meet the design requirements, which is also the key to the success of reinforced soil engineering.

- Waterproof and drainage measures: In the reinforced soil project, it is necessary to do a good job of drainage treatment inside and outside the wall; to protect the feet and prevent erosion; to set filter and drainage measures in the soil body, and to install geotextiles when necessary,

Fiber Glass Construction Technology

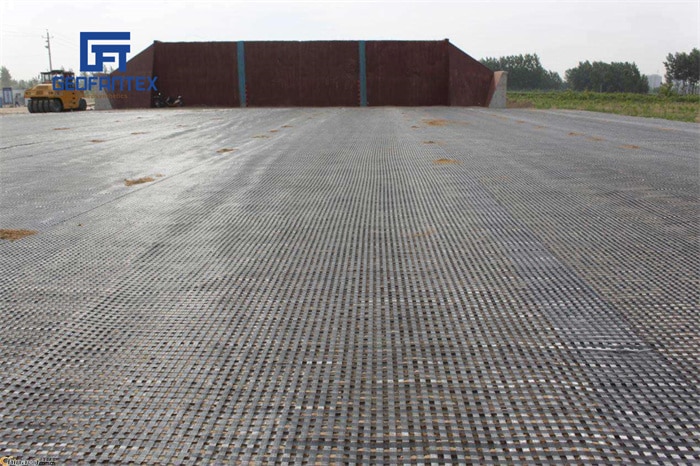

(1) First, release the side slope line of the subgrade accurately. In order to ensure the width of the subgrade, each side is widened by 0.5m. After leveling the air-dried base soil, statically press it twice with a 25T vibratory roller, and then four times with a 50T vibratory roller. , The uneven place is artificially leveled.

(2) Pave the medium (coarse) sand with a thickness of 0.3m. After manual leveling with mechanical leveling, the 25T vibratory roller will statically press twice.

(3) Lay geogrids. When laying geogrids, the bottom surface should be flat and dense. Generally, they should be laid flat, and straightened, not overlapped, curled, or kinked. Two adjacent geogrids need to overlap 0.2m, and The overlapping part of the geogrid along the lateral direction of the subgrade is connected with No. 8 iron wire every 1 meter, and on the laid grid, it is fixed on the ground with U-shaped nails every 1.5-2m.

(4) After the first layer of geogrid is laid, start to fill the second layer of 0.2m thick medium (coarse) sand. The method: transport the sand to the construction site by car and unload it on the side of the roadbed, and then push it forward with a bulldozer First, fill 0.1m within 2m on both sides of the subgrade, then turn over the first layer of geogrid and fill it with 0.1m of medium (coarse) sand. This kind of machine works on the geogrid that has not been filled with medium (coarse) sand, so as to ensure that the geogrid is flat and does not bulge or wrinkle. After the second layer of medium (coarse) sand is flat, it must be leveled. Measure to prevent uneven filling thickness. After the leveling is correct, use a 25T vibratory roller to statically press it twice.

(5) The construction method of the second layer of geogrid is the same as that of the first layer. Finally, 0.3m of medium (coarse) sand is filled. The filling method is the same as that of the first layer. After static pressure twice with a 25T road roller, reinforcement of the subgrade base is completed.

(6) After the third layer of medium (coarse) sand is rolled, lay two geogrids on both sides of the slope along the longitudinal direction of the line, with an overlap of 0.16m, and connect them in the same way, and then start the earthwork construction work, When laying geogrid for slope protection, it is necessary to measure the paved sideline for each layer, and ensure that the geogrid is buried 0.10m inside the slope after slope repair.

(7) Every time two layers of soil are filled with slope geogrid, that is, when the thickness is 0.8m, a layer of geogrid should be laid on both sides at the same time, and so on, until it is laid under the surface soil of the road shoulder.

(8) After the subgrade is filled, the side slope shall be repaired in time, and dry rubble protection shall be carried out at the foot of the slope. In addition to widening the subgrade by 0.3m on each side, 1.5% of the settlement shall be reserved.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)