+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

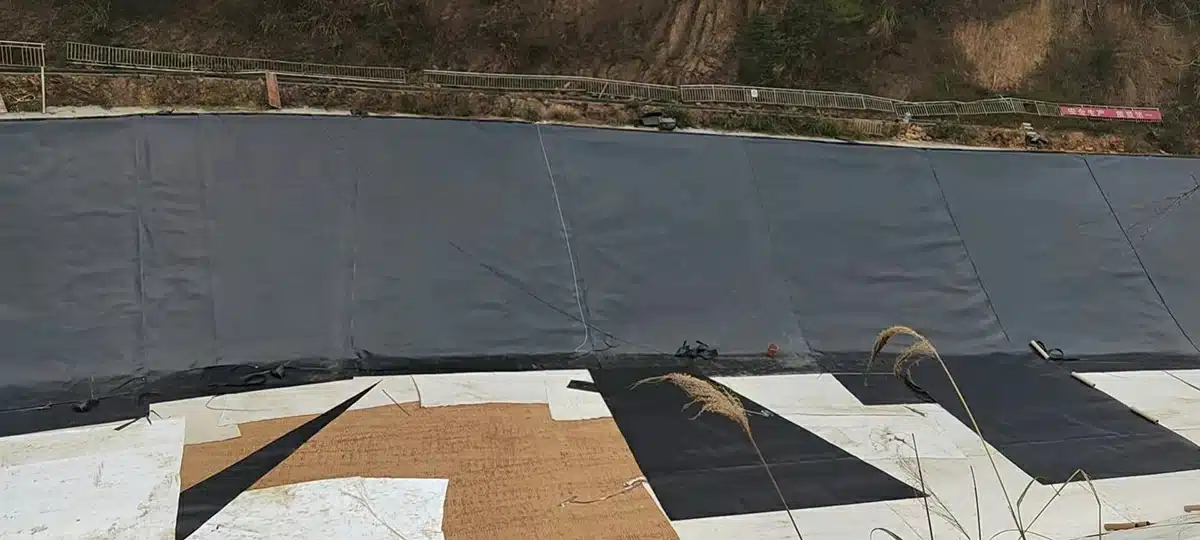

In the ever-evolving field of environmental engineering, the choice between geosynthetic clay liners (GCLs) and geomembranes stands as a critical decision point for projects involving landfill liners, containment solutions, and water management systems. Both materials offer unique benefits and have specific applications where they excel, with geomembranes being impermeable and serving as a barrier to fluid or gas migration. This article delves into the core differences, applications, and considerations between GCLs and geomembranes, providing insights for professionals and enthusiasts alike seeking to understand which solution best fits their environmental engineering needs.

What are Geosynthetic Clay Liners and Geomembranes, and How Do They Differ?

Geosynthetic Clay Liners (GCLs) and Geomembranes are both types of materials used in geotechnical and environmental engineering for containment, erosion control, and barrier applications, but they differ in composition and function.

Geosynthetic Clay Liners (GCLs):

- GCLs are composite materials comprised of a layer of bentonite clay sandwiched between two geotextiles or other geosynthetic materials.

- Bentonite clay, known for its swelling properties when hydrated, acts as the primary barrier against fluid migration.

- Geotextiles provide reinforcement and protection to the clay layer, preventing punctures and enhancing the overall mechanical properties of the liner.

- GCLs are commonly used in applications requiring both hydraulic containment (e.g., landfill liners) and erosion control (e.g., canal linings).

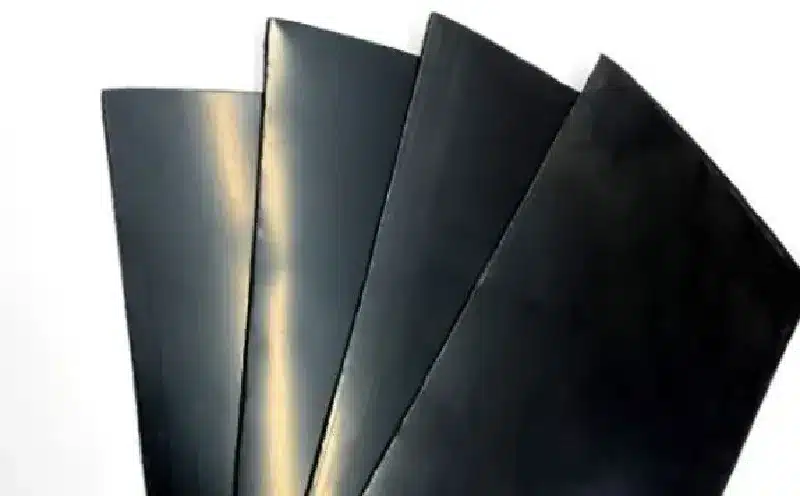

- Geomembranes are synthetic polymer sheets or membranes that serve as impermeable barriers to fluid and gas migration.

- They are manufactured from various materials such as high-density polyethylene (HDPE), polyvinyl chloride (PVC), ethylene propylene diene monomer (EPDM), and others.

- Geomembranes are typically homogeneous and do not contain natural clay components.

- They offer high chemical resistance, durability, and flexibility, making them suitable for a wide range of containment applications including landfill liners, pond liners, and reservoir covers.

Key Differences:

- Composition: GCLs contain a layer of natural bentonite clay sandwiched between geotextiles, while geomembranes are synthetic polymer sheets without clay components.

- Hydraulic Conductivity: GCLs rely on the swelling properties of bentonite clay to reduce hydraulic conductivity, whereas geomembranes achieve impermeability through the inherent properties of synthetic polymers.

- Applications: GCLs are often used in applications where both hydraulic containment and erosion control are required. Geomembranes are commonly employed when a high degree of impermeability and chemical resistance is needed, such as in landfill liners, pond liners, and floating covers.

In summary, while both GCLs and geomembranes are used for containment purposes, GCLs utilize a combination of natural clay and geotextiles, while geomembranes are synthetic polymer sheets designed for impermeability. The choice between them depends on the specific requirements of the project and the environmental conditions involved.

In What Situations Is Each Material Preferred?

Materials are selected based on their properties and suitability for specific applications. Here’s a general guideline for some common materials:

Metals:

- Preferred for structural applications due to their strength and durability.

- Used in construction, automotive, aerospace, and machinery industries.

- Ideal for components subjected to high stress or temperature.

- Examples include steel, aluminum, titanium, and copper.

Plastics:

- Preferred for lightweight and corrosion-resistant applications.

- Used in packaging, consumer products, automotive interiors, and medical devices.

- Ideal for parts requiring intricate shapes or insulation properties.

- Examples include polyethylene, polycarbonate, PVC, and ABS.

Ceramics:

- Preferred for high-temperature and wear-resistant applications.

- Used in aerospace, electronics, medical implants, and cutting tools.

- Ideal for parts exposed to extreme conditions or requiring electrical insulation.

- Examples include alumina, silicon carbide, and zirconia.

Composites:

- Preferred for applications requiring a combination of properties such as strength, lightweight, and corrosion resistance.

- Used in aerospace, automotive, marine, and sporting goods industries.

- Ideal for parts where weight reduction is critical or specific mechanical properties are needed.

- Examples include carbon fiber-reinforced polymers (CFRP), fiberglass, and kevlar.

Wood:

- Preferred for aesthetic and traditional applications.

- Used in furniture, construction, and crafts.

- Ideal for applications where a natural look or feel is desired.

- Examples include hardwoods like oak, maple, and softwoods like pine.

Glass:

- Preferred for transparent and brittle applications.

- Used in windows, containers, lenses, and electronic displays.

- Ideal for applications requiring optical clarity or chemical resistance.

- Examples include soda-lime glass, borosilicate glass, and quartz.

Rubber and Elastomers:

- Preferred for applications requiring flexibility and resilience.

- Used in seals, gaskets, tires, and vibration dampeners.

- Ideal for parts requiring shock absorption or sealing properties.

- Examples include natural rubber, silicone rubber, and neoprene.

The selection of materials depends on factors such as cost, availability, performance requirements, and environmental considerations. Additionally, advances in material science continually expand the range of available options and their applications.

What are the Environmental Considerations Associated with Each?

Environmental considerations associated with geotextiles and French drains can vary depending on their application and the materials used. Here are some key points to consider:

Geotextiles:

| Material Biodegradability | Some geotextiles are made from biodegradable materials, which can break down over time. This can be advantageous in certain applications to avoid long-term environmental impact. |

| Chemical Composition | Non-biodegradable geotextiles may contain synthetic materials like polypropylene or polyester. While durable, these materials can contribute to plastic waste if not properly managed. |

| Impact on Soil and Water | Geotextiles can affect soil permeability and drainage patterns, which might impact local ecosystems and water quality. Proper selection and installation are critical to mitigate negative effects. |

| End-of-Life Considerations | Disposal of geotextiles after their useful life is important. Recycling options for synthetic geotextiles are limited, and proper landfilling or incineration methods must be considered. |

French Drains:

| Water Quality | French drains are designed to manage water flow and prevent waterlogging. The drainage system should be planned to avoid contamination of water sources with sediment or pollutants. |

| Maintenance | Poorly maintained French drains can lead to clogging, which can affect local hydrology and potentially cause erosion or flooding. |

| Excavation and Construction | The process of installing French drains involves excavation, which can disturb soil and vegetation. Proper erosion control measures are essential during construction to prevent sediment runoff into nearby water bodies. |

| Long-term Stability | Ensuring the stability of French drains over time is crucial to prevent erosion or structural failure that could impact nearby ecosystems or infrastructure. |

Overall Considerations:

| Regulatory Compliance | Both geotextiles and French drains may be subject to local environmental regulations. Compliance with these regulations ensures that installations are environmentally responsible. |

| Lifecycle Assessment | Conducting a lifecycle assessment can help evaluate the environmental impacts of these systems from production to disposal, guiding decisions toward more sustainable practices. |

By addressing these considerations, engineers and designers can implement geotextiles and French drains in ways that minimize environmental impact and enhance sustainability.

How Do Costs Compare Between Geosynthetic Clay Liners and Geomembranes?

The costs of geosynthetic clay liners (GCLs) and geomembranes can vary based on several factors such as material type, thickness, installation requirements, and site-specific conditions. Here’s a general comparison:

Geosynthetic Clay Liners (GCLs):

- Material Cost: Generally lower compared to geomembranes.

- Installation Cost: Often less expensive due to easier installation techniques.

- Performance: Provides good hydraulic conductivity and sealing properties.

- Longevity: Typically has a shorter lifespan compared to geomembranes.

Geomembranes:

- Material Cost: Generally higher due to the type of polymer used (e.g., HDPE, PVC, EPDM).

- Installation Cost: Can be higher due to specialized installation techniques and equipment required.

- Performance: Offers excellent impermeability and durability.

- Longevity: Usually has a longer lifespan compared to GCLs.

Factors Influencing Costs:

- Site Conditions: Terrain, soil type, and environmental factors can influence material selection and installation costs.

- Design Requirements: Thickness, size of the liner needed, and specific engineering requirements.

- Installation Methods: The complexity of installation methods can impact labor costs.

- Maintenance and Lifespan: Considerations for long-term maintenance and replacement costs.

In summary, while geosynthetic clay liners may have lower initial costs and easier installation, geomembranes typically offer superior long-term performance and durability, albeit at a higher initial investment. Choosing between them depends on project-specific requirements, budget constraints, and expected lifespan considerations.

Choosing between geosynthetic clay liners and geomembranes involves a meticulous evaluation of project-specific needs, environmental impacts, and long-term performance expectations. While GCLs boast natural materials and self-healing capabilities, geomembranes stand out for their impermeability, superior chemical resistance, and durability. Guided by the particular requirements of the application and considering both immediate and long-term environmental and economic impacts, professionals can make informed decisions that enhance the sustainability and efficacy of their projects.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)