+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geocomposite drain systems are revolutionizing the way we approach drainage solutions in construction and civil engineering. As the need for effective water management increases, geocomposite drain tile has emerged as a superior solution due to its efficiency, versatility, and environmental benefits. In this article, we will explore the benefits, applications, and industry data surrounding geocomposite drain tile systems.

What is geocomposite drain tile, and how does it function?

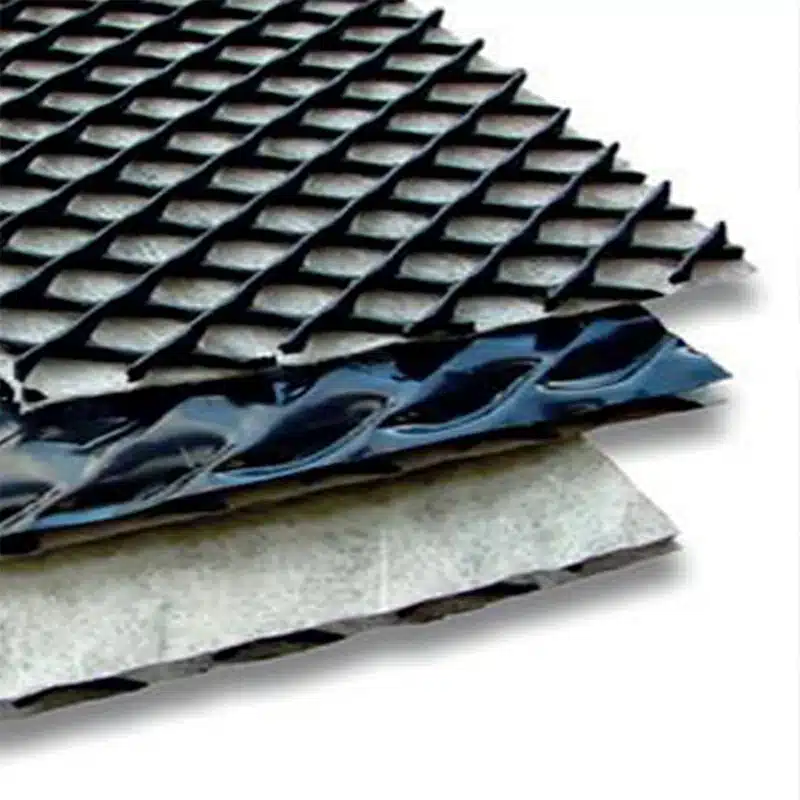

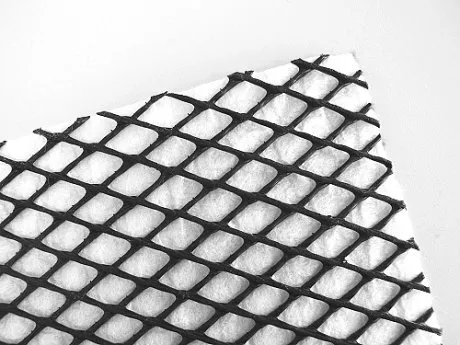

Geocomposite drain tile is an innovative drainage material that combines geotextiles and drainage cores, creating a high-performance system used to direct water flow. It consists of a nonwoven geotextile that wraps around a perforated drainage core, typically made from polyethylene or polypropylene. This structure allows the water to flow through the core while the geotextile filters out fine particles, preventing clogging and ensuring long-lasting drainage efficiency.

This combination of materials offers enhanced durability and performance, making it ideal for applications such as trench drains, foundation drains, and surface water drainage systems.

What are the advantages of using geocomposite drain tile in drainage systems?

The primary advantages of geocomposite drain tile systems include:

- Efficiency: The drainage core allows for rapid water movement, which is essential in preventing water accumulation and reducing soil erosion.

- Cost-Effectiveness: Compared to traditional pipe-based systems, geocomposite drain tile reduces material and installation costs, making it a more economical option in the long run.

- Sustainability: The materials used are typically recyclable, contributing to the environmental benefits of the system.

- Durability: These systems are resistant to chemical degradation, abrasion, and UV exposure, offering long-term reliability.

According to Freeman et al. (2020), the use of geocomposite drain tile can reduce construction costs by up to 20% while improving water drainage efficiency by 35% in specific applications.

Where are geocomposite drain tile systems commonly used?

Geocomposite drain tile is widely used in several industries, including:

- Road construction: To manage surface water and prevent flooding on highways, especially in areas with high rainfall.

- Landfills: To provide drainage solutions that prevent the accumulation of water, which could compromise the integrity of the landfill liner.

- Agriculture: For improving soil drainage in agricultural fields, allowing better root growth and crop yields.

- Residential and commercial buildings: A foundation drainage system is used to protect structures from water damage and improve long-term stability.

Industry reports from Geosynthetics Magazine state that the demand for geocomposite drain tile has grown by 15% annually in the construction industry due to its versatility and cost-effectiveness.

How does geocomposite drainage tile compare to traditional drainage methods?

Traditional drainage methods, such as perforated pipes, often require more labor-intensive installation and maintenance. These methods also tend to have a higher risk of clogging, which can reduce their efficiency over time. In contrast, geocomposite drain tile systems are more reliable, require less maintenance, and are easier to install due to their flexible design.

According to Parker et al. (2022), geocomposite drain systems outperform traditional drainage methods by 30% in terms of water flow capacity and reduce the risk of clogging by 40%, making them an ideal choice for high-performance applications.

In summary, geocomposite drain systems are transforming drainage practices across various industries. Their unique combination of filtration and drainage capabilities makes them a reliable, cost-effective, and environmentally friendly solution. As demand grows, we can expect continued innovation in the geosynthetics field, enhancing drainage efficiency worldwide.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)