+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

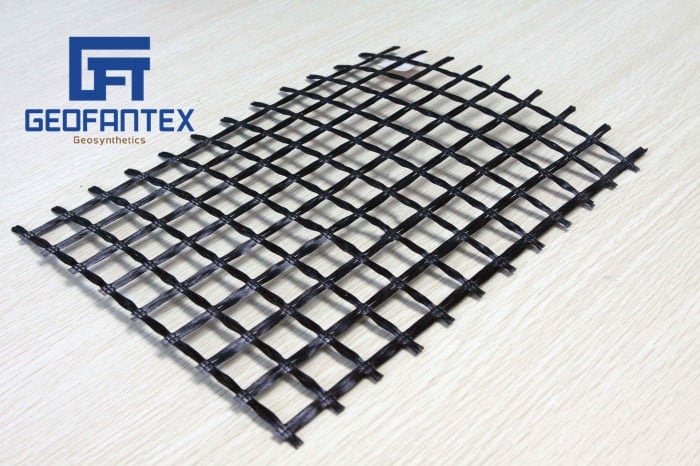

A geogrid is geosynthetic material used to reinforce soils and similar materials. Geogrids are commonly used to reinforce retaining walls, as well as subbases or subsoils below roads or structures. Soils pull apart under tension. Geogrids are commonly made of polymer materials, such as polyester, polyvinyl alcohol, polyethylene or polypropylene.

They may be woven or knitted from yarns, heat-welded from strips of material, or produced by punching a regular pattern of holes in sheets of material, then stretched into a grid. The geogrids are manufactured high strength reinforcement grids that come in rolls of various sizes and strengths. The soil can strike through the apertures and the two materials interlock together to give composite behavior.

What Is Geogrid Used For Roads?

Geogrids are commonly used to stabilize poor soils during sitework. In pavement structures, Tensar geogrids create a “snowshoe effect” over soft subgrades by locking aggregate particles more efficiently during compaction, stiffening the granular platform and reducing subgrade stress.

What Is The Use Of Geotextile And Geogrid In Road Construction?

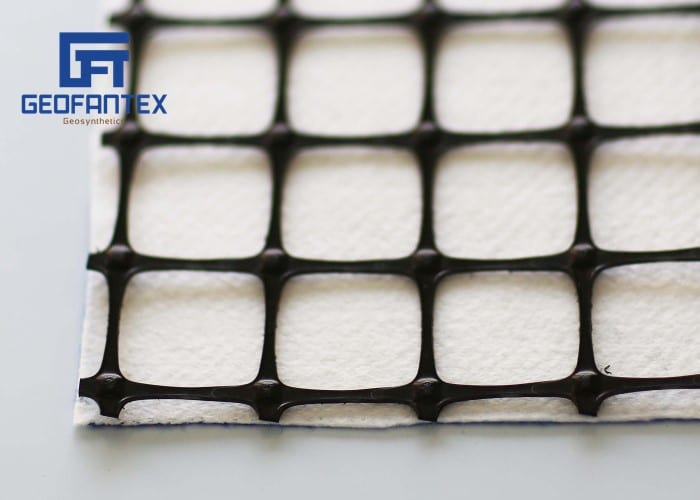

The geogrid can also be combined with a geotextile separation layer to prevent fines from migrating into more open graded base layers and further enhance the roadway performance through improved drainage as well as reinforcement.

What Is Geogrid And When To Use?

Geogrids provide reinforcement, stabilization, and even filtration when used with properly sized aggregate fills. Made from polymers such as polypropylene, polyethylene, or polyester, they are used widely in civil engineering applications.

Manufacturing and functional mechanism of geogrids:

There are three methods for manufacturing of geogrids, each of them is explained below.

- Extrusion: In this method, a flat polymeric sheet of material is made into a geogrid by extrusion and holes of desired dimensions are punched in the flat sheet to form the apertures.

- Weaving or Knitting: These geogrids are manufactured by weaving fibrous yarns and apertures are formed in between the flexible joints. These types of geogrids have high tenacity.

- Welding and Extrusion: Tese geogrids have manufactured the extrusion of ribs that is carried out by passing it through rollers, then they are sent to the welding section to form apertures.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)