+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

When it comes to geosynthetics, geogrid prices play a crucial role in project budgeting. Understanding these prices can help you make informed decisions about the materials you choose for your construction or infrastructure project.

What are the main factors influencing geogrid prices?

The main factors influencing geogrid prices include:

- Raw Material Costs: Geogrids are commonly made from polymers like HDPE, PP, or PET. Fluctuations in oil prices and resin supply directly impact these material costs.

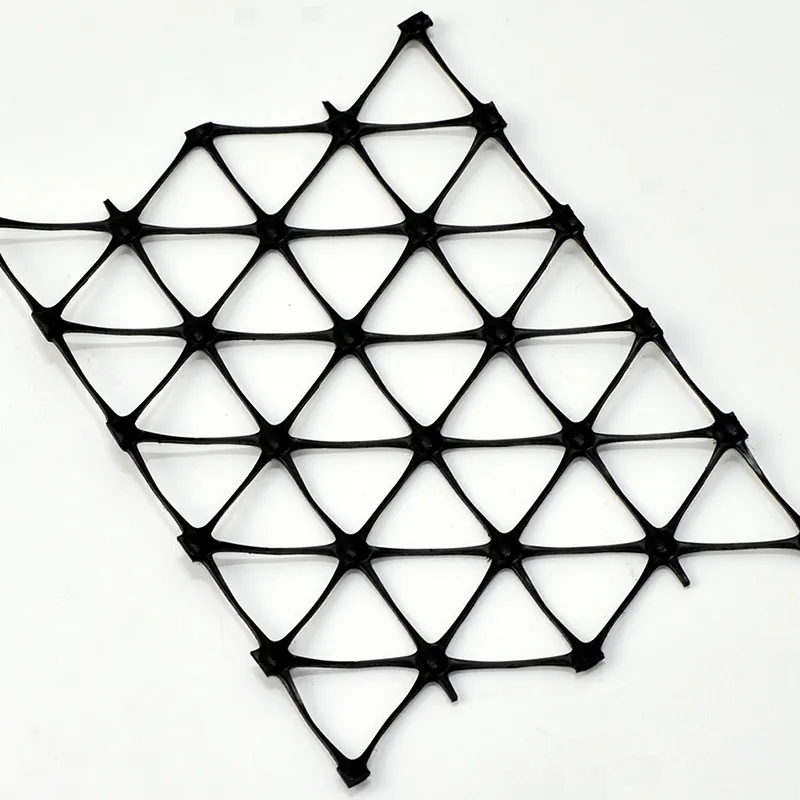

- Type of Geogrid: Uniaxial, biaxial, and triaxial geogrids vary in production complexity and applications. Uniaxial geogrids (used for retaining walls) are often more expensive due to higher tensile strength requirements.

- Manufacturing Process: Different methods (extrusion, weaving, knitting, welding) affect cost. Woven and knitted PET geogrids typically require more labor and processing time, increasing their price.

- Strength and Specifications: Higher tensile strength, durability, and UV resistance usually mean higher costs. Custom grades for critical infrastructure are priced higher.

- Quantity and Order Size: Bulk orders reduce unit costs due to economies of scale.

- Geogrid Coating or Lamination: Some geogrids are PVC-coated or bitumen-coated for added durability or compatibility with asphalt—this adds to the cost.

- Logistics and Transportation: Geogrids are bulky and may incur significant shipping costs, especially for international delivery.

- Certification and Compliance:Products certified for ASTM, ISO, CE, or government projects often carry a premium due to testing and compliance expenses.

How can I find the best deal on geogrid prices?

To find competitive geogrid prices, it’s important to compare suppliers and consider bulk buying options. Additionally, getting multiple quotes and negotiating based on your project’s volume can help lower the overall cost. Always ensure that quality is not compromised for the sake of a lower price.

Are there any cost-saving alternatives to traditional geogrids?

While traditional geogrids can be expensive, some alternatives, like woven geotextiles or different composite materials may offer similar benefits at a lower price. However, these alternatives may not always perform as effectively under certain conditions, so it’s essential to assess the project requirements before switching.

How does the project scale affect geogrid prices?

For large-scale projects, geogrid prices tend to decrease per unit due to economies of scale. Suppliers often offer discounts for bulk purchases, which can significantly reduce the overall cost of the materials needed. However, for smaller projects, the unit price may be higher.

Understanding geogrid prices is essential for budgeting construction or infrastructure projects. The cost of geogrids is influenced by factors like material type, manufacturer, and quantity. To find the best deals, it’s important to compare suppliers and consider bulk purchasing. Alternatives such as woven geotextiles can offer cost savings but may not always provide the same performance. Additionally, larger projects tend to benefit from economies of scale, which can lower the per-unit price of geogrids. By considering these factors, you can make informed decisions that balance cost and quality for your project.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)