+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

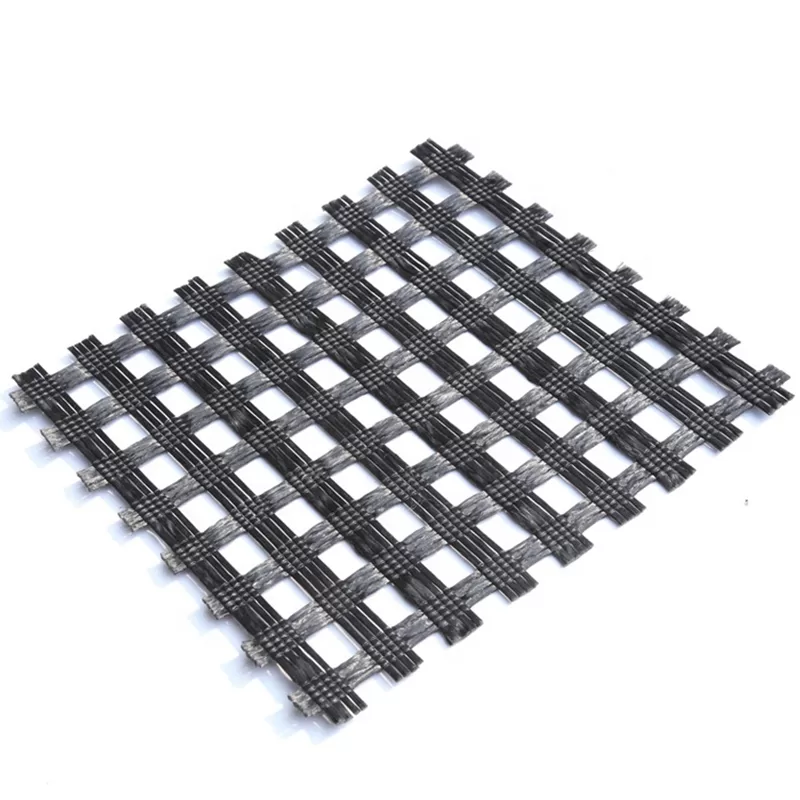

In the field of civil engineering, the use of geogrids in the construction of shallow foundations has become increasingly popular due to their ability to enhance soil stabilization and support. Geogrids are polymeric grids that are used to reinforce soil under structures like roads, buildings, and other infrastructure. This article explores how geogrids function, their types, installation methods, and the reasons for their necessity in modern construction projects.

What is the bearing capacity of a geogrid?

The bearing capacity of a geogrid refers to its ability to distribute loads from a structure over a wider area of soil than would otherwise be possible without reinforcement. This capacity largely depends on the type of geogrid, the soil properties, and the loading conditions. To achieve maximum load capacity, the effective length of the geogrid to be placed should be in a range of 3–6 times the width of the footing. This optimal sizing helps ensure that geogrids can significantly increase a soil’s strength and prevent issues like sinking or uneven settlement. By creating a more stable base, geogrids can enhance the load-bearing capacity of soils, especially those that are weak or loose.

What are the three types of geogrid?

Geogrids can be categorized into several types based on their manufacturing processes and structural characteristics, including Uniaxial, Biaxial, Triaxial (Triax®), and Geogrid-Geotextile Composites:

- Uniaxial Geogrids: These are designed to be strong in one direction and are commonly used in slope stabilization and retaining walls where tension is predominantly in one direction.

- Biaxial Geogrids: These provide strength in two directions and are often used under roadways and pavements where equal stress distribution is required in both the longitudinal and transverse directions.

- Triaxial Geogrids (Triax®): With strength in three directions, Triaxial geogrids offer an enhanced level of stabilization and are suitable for applications where multidirectional stresses occur, such as in large area foundations and embankments.

- Geogrid-Geotextile Composites: These combine the reinforcement properties of geogrids with the separation and filtration functions of geotextiles, making them particularly effective in projects requiring both soil stabilization and water filtration.

How are geogrids installed?

Geogrids can be categorized into three main types based on their manufacturing processes and structural characteristics:

The installation of geogrids involves several steps that must be carefully followed to ensure effectiveness:

- Site Preparation: Clearing the site of vegetation, debris, and any obstacles that might interfere with the geogrid installation.

- Soil Grading and Compaction: The soil is graded to create a smooth, even surface and then compacted to enhance its density and load-bearing capacity.

- Geogrid Deployment: The geogrid is rolled out over the prepared soil surface and allowed to follow the natural contours of the ground. It must be laid flat and pulled tight to avoid wrinkles that could affect its performance.

- Layering: Soil is then layered over the geogrid and compacted; this process may be repeated in multiple layers depending on the project requirements.

- Final Construction: The final layer of soil or the structure itself is added on top of the compacted layers containing the geogrid.

Why do you need Geogrid?

Geogrids are essential for several reasons in modern construction:

- Soil Reinforcement: They enhance the mechanical properties of the soil, making it more stable and suitable for supporting heavy loads. Additionally, by stabilizing unsuitable subgrades, geogrids reduce the depth of excavation required, further simplifying construction processes.

- Cost Efficiency: By improving the strength of native soils, geogrids reduce the need for expensive imported materials and complex foundation systems. This not only lowers project costs but also speeds up construction timelines.

- Environmental Benefits: Geogrids help to reduce the environmental impact of construction by using less material and facilitating the use of locally sourced soils. This approach minimizes the carbon footprint associated with material transport and site preparation.

- Versatility and Durability: Suitable for a variety of soil types and conditions, geogrids contribute to the longevity of structures by preventing soil erosion and settlement. This versatility makes them a reliable choice for diverse construction needs.

Geogrids play a crucial role in the construction of shallow foundations, offering enhanced stability, cost-effectiveness, and environmental sustainability. Understanding the different types of geogrids, their installation processes, and their specific benefits can help engineers and builders choose the right solution for their projects, ensuring the longevity and durability of the constructed structures. Whether in roads, commercial buildings, or residential areas, geogrids provide a foundation for success in numerous engineering applications.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)