+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geomembranes are critical components used in environmental engineering, particularly at landfill sites where they serve as barriers to prevent leachate migration and gas emissions. The durability and longevity of these geomembrane covers are vital to maintaining environmental safety and efficiency in waste management. This article explores the lifespan of geomembrane covers used in landfill sites, factors affecting their durability, and how they can be maintained to extend their service life.

What Is a Geomembrane and What Role Does It Play in Landfills?

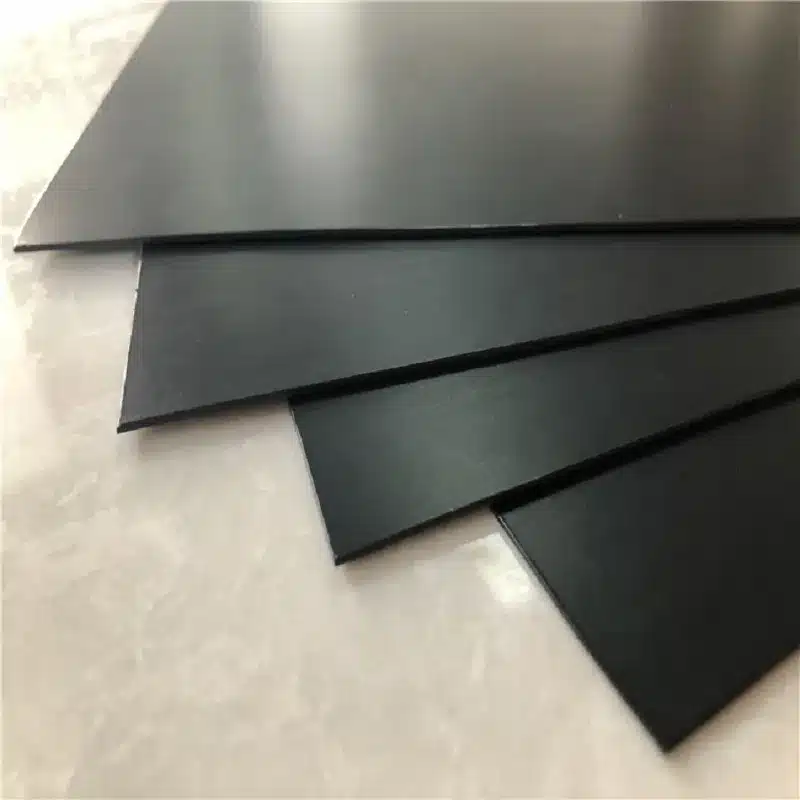

A geomembrane is a low-permeability synthetic liner or barrier used in environmental and geotechnical engineering to control the migration of liquids and gases. In landfill applications, geomembranes are a core element of the containment system, designed to isolate waste materials from the surrounding soil, groundwater, and atmosphere.

Key Roles of Geomembranes in Landfills:

- Primary Containment Barrier: Acts as the main impermeable layer preventing leachate generated from waste decomposition from infiltrating underlying soils and groundwater systems.

- Groundwater and Soil Protection: Provides a continuous hydraulic barrier that limits the downward and lateral migration of hazardous substances, particularly in areas with shallow water tables or environmentally sensitive zones.

- Landfill Gas Control: Works in conjunction with gas collection and venting systems to contain and direct landfill gases such as methane and carbon dioxide, supporting safe release, flaring, or energy recovery.

- Structural and System Integrity: Contributes to overall landfill stability by containing waste and leachate within the engineered system, reducing risks related to slope instability, erosion, and liner failure.

- Long-Term Durability: Engineered to withstand chemical exposure, mechanical stress, and temperature variation, geomembranes ensure reliable performance throughout the landfill’s operational and post-closure life.

Geomembranes are indispensable in modern landfill design, ensuring environmental protection, regulatory compliance, and long-term operational efficiency. Their correct selection and integration are critical to the safe containment of waste and the protection of surrounding ecosystems.

How Long Do Geomembrane Covers Typically Last in Landfills?

The lifespan of a geomembrane cover in a landfill depends on material type, environmental conditions, and maintenance practices. Generally, geomembranes can last anywhere from 10 to 50 years, with proper selection and care. Key considerations include:

- Material Type:

- HDPE (High-Density Polyethylene): Extremely durable, resistant to chemicals and UV, often lasting 20–30 years or more.

- PVC and EPDM: Moderate durability, with slightly shorter lifespans depending on exposure conditions.

- Environmental Exposure: UV radiation, temperature fluctuations, chemical interaction with leachate, and physical stress can all reduce longevity.

- Installation Quality: Correct installation by experienced technicians is critical; poor workmanship can lead to early tears or leaks.

- Maintenance Practices: Routine inspections and timely repairs extend service life by preventing minor damage from escalating.

In summary, HDPE geomembranes installed and maintained correctly are among the most long-lasting options, often exceeding 30 years, while other materials may require more frequent monitoring and replacement.

What Factors Affect the Longevity of Geomembrane Covers?

The durability of geomembrane covers is influenced by several factors:

- UV Radiation: Prolonged exposure to sunlight can degrade the materials unless they are properly stabilized against UV radiation.

- Chemical Exposure: Interaction with harsh chemicals in the waste can degrade the geomembrane faster.

- Physical Stress: Mechanical pressures, punctures, or tears from the overlying or underlying materials can compromise the integrity of the cover.

- Installation Quality: Poor installation can lead to early failures, such as leaks or tears.

- Environmental Conditions: Temperature fluctuations and extreme weather conditions can also affect the lifespan of geomembrane covers.

How Can the Life of a Geomembrane Cover be Extended?

- Primary Impermeable Barrier: Serves as the central containment layer, preventing leachate formed during waste decomposition from penetrating surrounding soil and groundwater systems.

- Groundwater Safeguard: Creates a continuous hydraulic seal that restricts vertical and lateral migration of contaminants, especially in regions with high groundwater levels or sensitive environmental conditions.

- Landfill Gas Management: Integrates with gas collection and venting systems to control methane and carbon dioxide movement, enabling safe flaring or energy recovery while reducing emission risks.

- System Stability Support: Enhances landfill structural integrity by confining waste and liquids within the engineered liner system, minimizing risks of slope failure, erosion, or containment breaches.

- Chemical and Mechanical Resistance: Designed to resist aggressive leachate, temperature fluctuations, and mechanical stresses, ensuring consistent performance over long operational periods.

- Environmental Compliance Assurance: Plays a key role in meeting environmental regulations and safety standards by maintaining long-term containment effectiveness.

Geomembranes are essential components in modern landfill engineering, providing reliable containment, environmental protection, and operational efficiency when properly selected, installed, and maintained.

The lifespan of a geomembrane cover at a landfill site is influenced by multiple factors but typically ranges from 10 to 30 years. By understanding the roles and types of geomembranes, acknowledging the factors that impact their durability, and implementing strategies to extend their life, landfill operators can ensure effective and long-lasting waste containment solutions. Regular maintenance and proactive management are key to maximizing the utility and effectiveness of geomembrane covers in preserving environmental safety.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)