+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

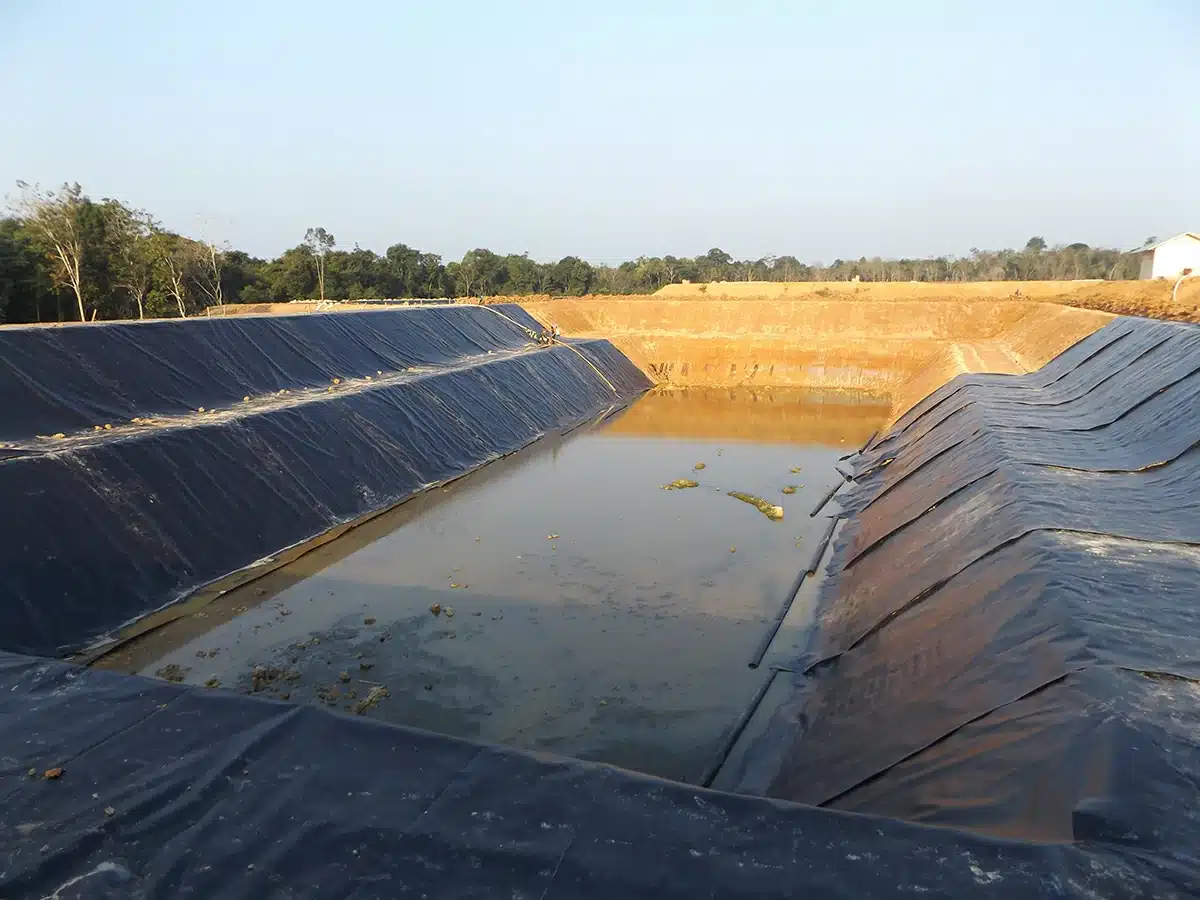

A geomembrane liner is one of the most critical components in modern geosynthetics applications, especially for industries dealing with environmental containment, wastewater treatment, mining, and agriculture. In this article, we’ll address four frequently asked questions to help you understand how geomembrane liners solve real-world engineering and environmental challenges.

What is a Geomembrane Liner and Why Is It Essential in Geosynthetics?

A geomembrane liner is a low-permeability synthetic membrane designed to control the migration of fluids or gases in engineered projects, structures, or systems. It is essential in geosynthetics because it provides an impermeable barrier, making it ideal for applications such as:

- Landfill containment to prevent leachate from contaminating groundwater.

- Water reservoirs to minimize seepage and maintain water levels.

- Mining tailings dams for secure containment of tailings.

- Industrial chemical containment due to its chemical resistance and durability.

By preventing leaks and seepage, geomembrane liners reduce environmental risks, ensure long-term structural stability, and support compliance with safety and environmental regulations.

How Does a Geomembrane Liner Prevent Leaks in Waste Management Projects?

In landfills and hazardous waste containment facilities, the risk of toxic leaks is high without proper lining systems. A geomembrane liner acts as the first line of defense against leachate infiltration into groundwater. Its chemical resistance and high tensile strength help it maintain integrity under extreme stress, thermal changes, and prolonged chemical exposure, making it indispensable for environmental protection.

What Types of Geomembrane Liners Are Best for Mining and Industrial Use?

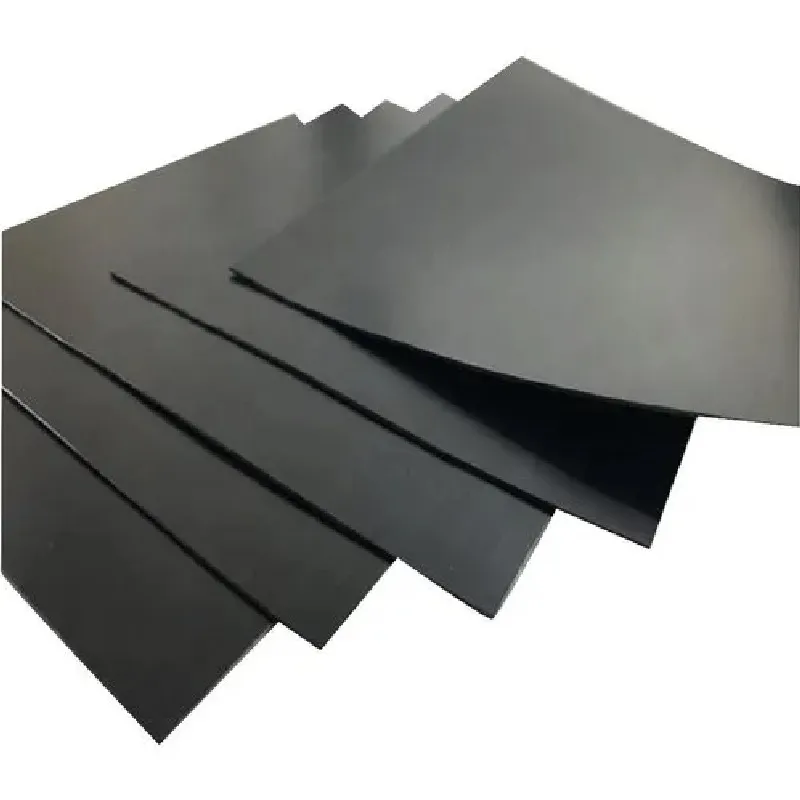

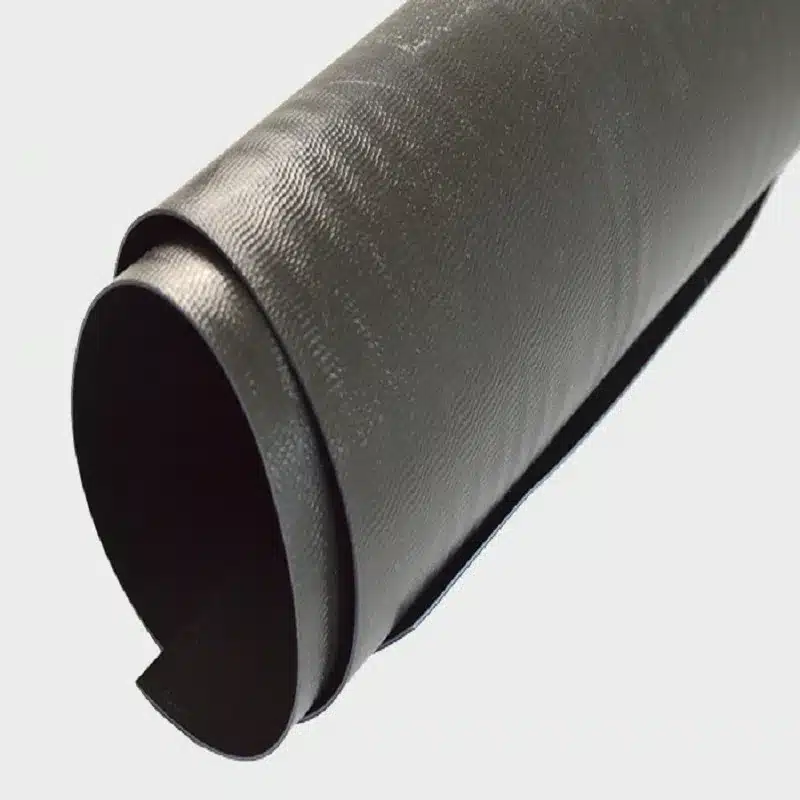

For mining applications, High-Density Polyethylene (HDPE) geomembranes are widely used due to their strength and UV resistance. Industries requiring chemical containment often prefer PVC or LLDPE liners for their flexibility. The selection of a geomembrane liner depends on site conditions, chemical compatibility, and mechanical demands, which is why expert consultation is essential before installation.

How Are Geomembrane Liners Installed and Maintained to Ensure Long-Term Performance?

Installation of a geomembrane liner involves surface preparation, welding or seaming panels together, and quality control testing (like air channel testing for seam integrity). Regular inspections, especially in high-stress environments, ensure the liner remains intact. Proper anchoring, protection layers (like geotextiles), and correct welding techniques all contribute to extending the service life of the liner.

In summary, a geomembrane liner is an essential solution in geosynthetics, offering superior containment, environmental protection, and durability across various industries. Whether you’re managing waste, mining operations, or water reservoirs, selecting the right liner and ensuring proper installation is key to long-term performance and regulatory compliance.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)