+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

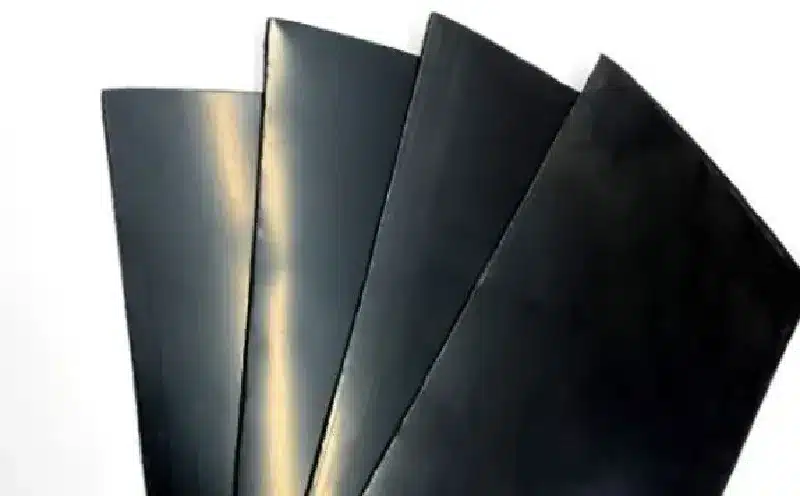

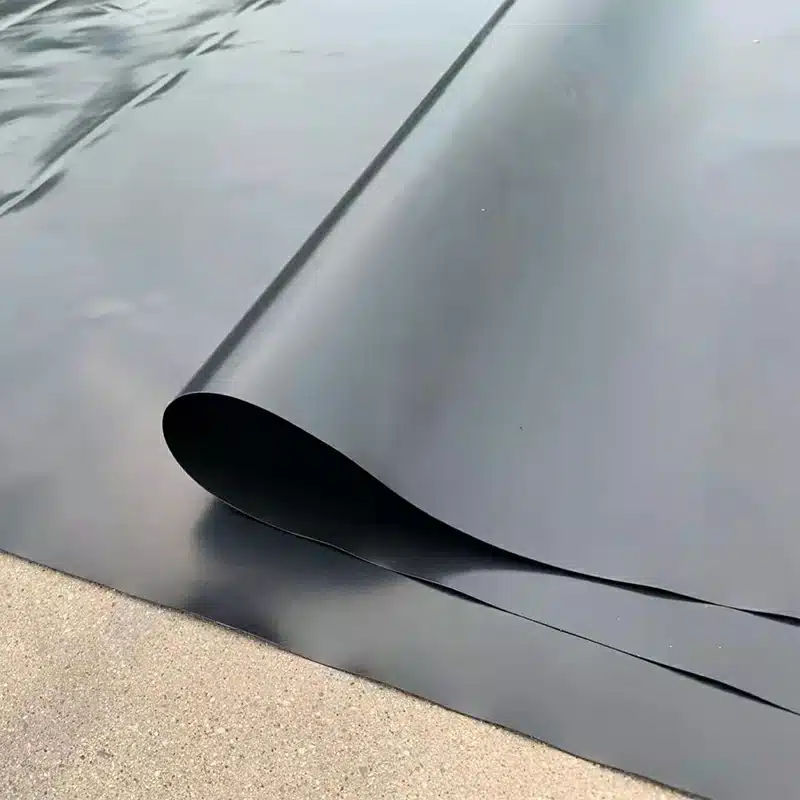

Waterproof geomembranes are critical components in various engineering and environmental projects, serving as reliable barriers to prevent the movement of fluids, and ensuring the integrity of structures like landfills, ponds, and reservoirs. These synthetic membranes are essential for maintaining environmental sustainability, protecting groundwater, and ensuring that hazardous substances do not seep into the surrounding ecosystem. In this article, we’ll explore the key aspects of waterproof geomembranes, including their waterproofing capabilities, sealing methods, longevity, and overall importance.

Is Geomembrane Waterproof?

Yes, geomembranes are designed to be highly waterproof. Geomembranes are one of the most versatile products used in SUDS systems, waterproofing, landfill sites, and below-ground drainage containment. They are made from synthetic polymers like High-Density Polyethylene (HDPE), Polyvinyl Chloride (PVC), or Ethylene Propylene Diene Monomer (EPDM), which are specifically engineered to create an impermeable barrier. This barrier effectively prevents the passage of liquids, making geomembranes ideal for applications where fluid containment is critical, such as in landfills, water reservoirs, and mining operations.

How Do You Seal a Geomembrane?

Sealing a geomembrane involves careful installation to ensure there are no leaks or weak points in the barrier. The most common method for sealing geomembranes is the heat-welding process, which can be done using hot wedge welding or extrusion welding techniques. These methods involve melting the edges of the geomembrane sheets and pressing them together to form a strong, continuous bond. Additionally, adhesive tapes or mechanical fasteners may be used in certain applications to reinforce the seams and ensure a watertight seal.

What Is the Life Expectancy of a Geomembrane?

The life expectancy of a geomembrane can vary depending on the material used, environmental conditions, and the quality of installation. Generally, geomembranes made from HDPE can last between 50-100 years or more, depending on exposure to UV radiation, temperature fluctuations, and chemical interactions. Proper installation and maintenance can significantly extend the life of a geomembrane, ensuring long-term protection and performance.

Why Is Geomembrane Important?

Geomembranes play a crucial role in environmental protection by providing a reliable barrier against the infiltration or leakage of hazardous substances, preventing the seepage of pollutants and harmful substances into water bodies. They are essential in waste management, preventing contaminants from entering the soil and groundwater. In water management, geomembranes help conserve water resources by preventing leaks in reservoirs and canals. Their use is vital in various industries, including agriculture, mining, and construction, where the containment of liquids and protection of natural resources is of utmost importance.

Waterproof geomembranes are indispensable in modern engineering and environmental protection. Their ability to create an impermeable barrier, combined with advanced sealing techniques and long life expectancy, makes them a key component in safeguarding our environment. Understanding the importance of geomembranes in various applications highlights their role in promoting sustainability and protecting natural resources for future generations.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)