+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

The term geonet geosynthetics refers to a family of polymer products engineered primarily for in-plane drainage, used in combination with other geosynthetics to control water and gas in highways, landfills, tunnels, mining platforms and green infrastructure.

What are geonet geosynthetics and how do they function in drainage systems?

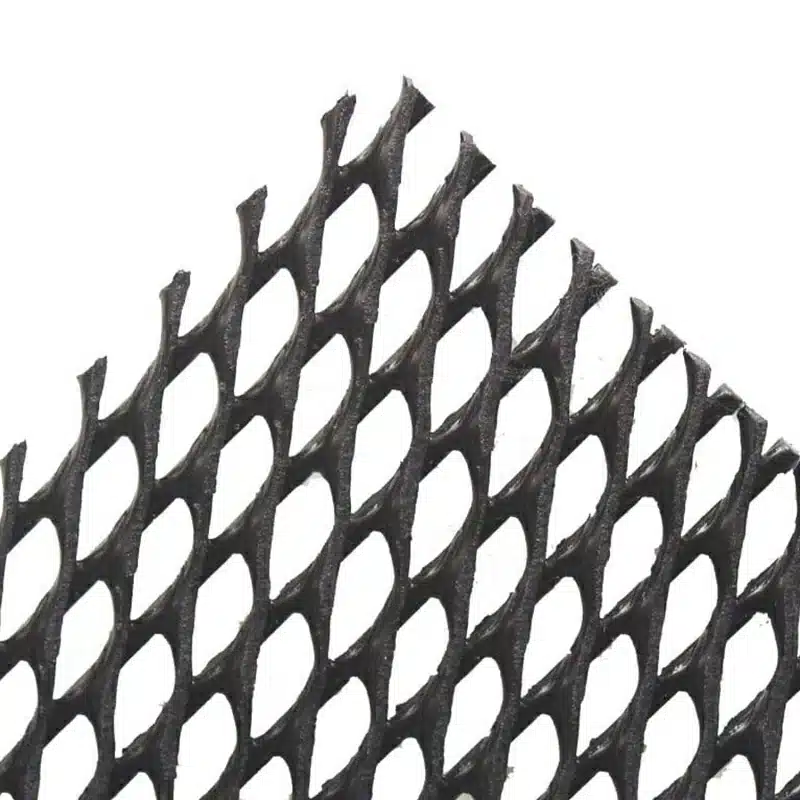

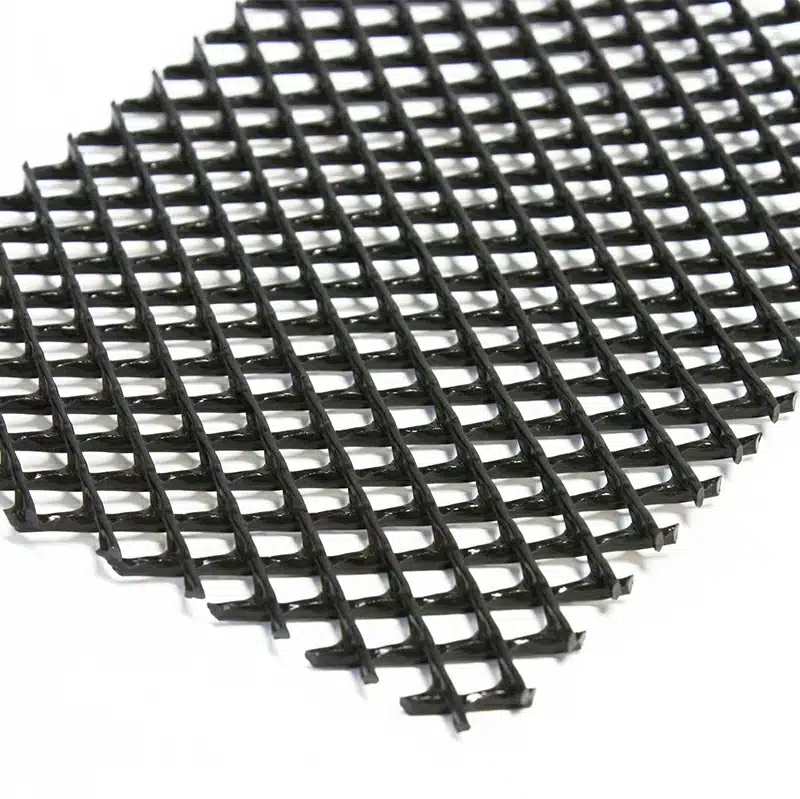

Geonets are three-dimensional polymeric cores made from HDPE and arranged in biplanar or triplanar rib structures to form continuous flow channels. When specified as geonet geosynthetics, they are typically integrated into drainage geocomposites where the geonet core is laminated with geotextiles for separation and filtration.

Common functions include:

- Leachate and gas collection in landfill systems

- Subsurface drainage for pavements and embankments

- Vertical drainage behind retaining walls and tunnels

- Green roof drainage with membrane protection

The laminated geotextile prevents fines from clogging the channels and preserves long-term transmissivity. Geonet-based systems have increasingly replaced granular drains due to reduced excavation, reduced carbon footprint and predictable hydraulic performance.

When installed above geomembranes in landfill cells, geonets create high-capacity flow paths for leachate and gas. This interacts directly with high-lighted anchor text for internal linking such as “geosynthetics drainage systems” and “landfill leachate collection” to support engineered containment solutions.

How large is the market opportunity for geonet-based drainage systems?

Industry data shows rapid expansion of the drainage and containment segment where geonets are widely used:

- Global geosynthetics market valued at USD 14.04 billion in 2023 and projected to reach USD 23.10 billion by 2030 at 7.4% CAGR (Next Move Strategy Consulting, 2024)

- Installed area demand forecasted at 9.0 billion m² by 2028 (Freedonia Group, 2024)

- Geonets and drainage composites used in 70% of modern engineered landfill, mining and green roof drainage systems (MarketsandMarkets, 2024)

Drivers include:

- Infrastructure stimulus spending (roads, rails, ports)

- Landfill modernization & mining tailings expansion

- Environmental compliance (leachate, groundwater, stormwater)

- Cost & carbon reduction initiatives in civil works

For buyers and specifiers, this means expanded supplier base, better standards and competitive pricing for drainage layers that outperform granular alternatives.

What performance advantages do geonet geosynthetics offer over granular drains?

Key competitive advantages include:

- High transmissivity under long-term load

Rib geometry maintains open channels under compressive load where granular drains may settle or crush. - Reduction in excavation and material logistics

Thin drainage composite layers eliminate 300–600 mm granular drains, minimizing trucking, fuel and material waste. - Integrated filtration and separation

The geotextile component enables controlled filtration and prevents fines from entering the drainage core. This advantage links directly to high-lighted anchors such as “geotextile filtration” and “geonet composites”. - Sustainability benefits

LCA studies (IGS reports) indicate geosynthetic solutions can deliver up to 75% CO₂ reduction vs. concrete or steel alternatives, reinforcing both carbon and cost benefits.

What trends and innovations are shaping future development of geonet geosynthetics?

- Multi-functional geocomposites

Integrating drainage with protection, separation and barrier functions in single-roll solutions, often combined with “geomembranes” for landfill and waterproofing applications. - High-load and chemical-resistant mining systems

New HDPE formulations provide stronger creep stability for tailings, heap leach pads and industrial lagoons. - Regulatory-driven landfill upgrades in APAC + LATAM

National waste codes and mining regulations are pushing demand for engineered drainage layers and geosynthetic barriers. - Circular design & carbon accounting

Recyclability, embodied carbon tracking and LCA disclosures are increasingly required in bidding documentation for civil projects.

In summary, geonet geosynthetics have transitioned from niche drainage components into strategic infrastructure materials that enable compact, durable and sustainable drainage solutions in modern civil and environmental engineering.

Geonet geosynthetics have become an essential component in modern drainage, containment, and environmental protection systems due to their engineered hydraulic performance, reduced material usage, and sustainability benefits. By replacing thick granular drainage layers with thin, high-transmissivity composites, they enable more efficient landfill leachate management, mining tailings drainage, and subsurface water control in transportation infrastructure and urban green systems. Supported by a growing global geosynthetics market, tightening regulatory standards, and increasing carbon-reduction pressures, geonet-based solutions are positioned for continued growth in both civil and environmental engineering. Their combination of technical efficiency, market scalability, and environmental value makes them a strategic material class for future infrastructure development.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)