+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

In civil engineering and environmental applications, understanding the differences between geonet vs geotextile is crucial for selecting the right material. These geosynthetics play distinct yet complementary roles in drainage, separation, and soil reinforcement systems.

What Is a Geonet Used For?

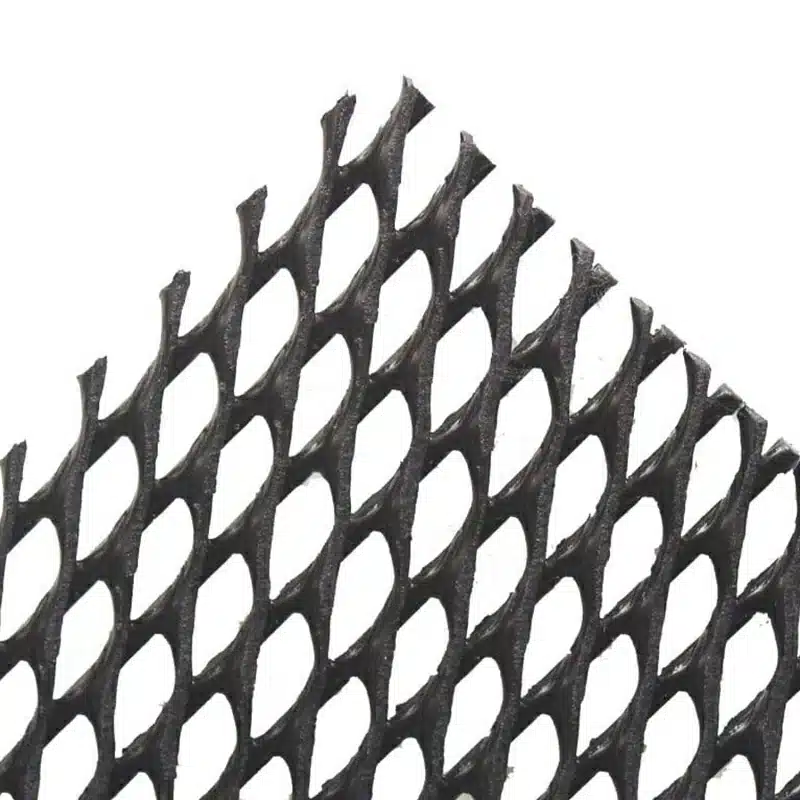

A geonet is primarily used for high-efficiency drainage in civil engineering and environmental projects. Made from HDPE with a three-dimensional net-like structure, it creates continuous flow channels that allow water and gas to move rapidly within a plane.

- Drainage Control: Geonets divert groundwater, leachate, and gas to prevent pressure buildup behind retaining walls, under roadways, and within landfill systems.

- Structural Protection: By relieving hydrostatic pressure, they help maintain soil stability and protect adjacent structures.

- System Integration: Geonets are often paired with geotextiles to form geocomposites, combining filtration and drainage to prevent clogging and ensure long-term performance.

- Long-Term Durability: Their high compressive strength and chemical resistance make them suitable for heavy-load, long-life infrastructure applications.

What is the difference between geotextile and geonet?

The difference between geotextile vs geonet lies mainly in structure, function, and hydraulic behavior. Although both are geosynthetics, they serve distinct engineering purposes.

| Geotextile | Geonet | |

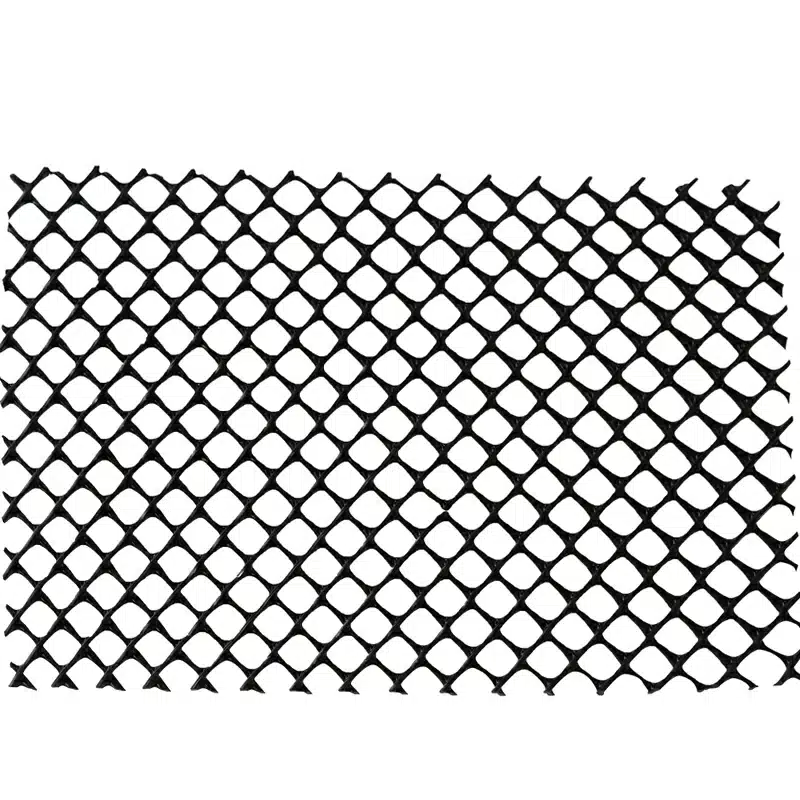

| Structure | Permeable fabric (woven or nonwoven) | Three-dimensional net-like core |

| Material | Polypropylene (PP) or Polyester (PET) | High-Density Polyethylene (HDPE) |

| Primary Functions | Separation: Prevents soil layer mixing Filtration: Allows water flow while retaining fines Reinforcement: Improves soil strength and load distribution Erosion Control: Stabilizes slopes and surfaces | Drainage: High-capacity in-plane fluid and gas conveyance Pressure Relief: Reduces hydrostatic and gas pressure |

| Flow Direction | Through-plane (vertical permeability) | In-plane (horizontal flow) |

| Typical Applications | Road subgrades Landfill filtration layers Drainage trenches Erosion protection systems | Landfill leachate and gas collection Retaining wall drainage Tunnel and foundation drainage systems |

| Key Engineering Distinction | Geotextiles filter and separate, controlling soil movement while allowing water to pass. | Geonets drain, rapidly transporting liquids or gases within a layer. |

| Combined Use | Geotextile: Filters soil particles | Geonet: Provides continuous drainage channels This combination prevents clogging and ensures long-term hydraulic performance. |

How do engineers decide between geonet and geotextile for a project?

- Project Objective: The choice between geonet and geotextile depends primarily on the intended function. Use geotextiles when the goal is to allow water passage while retaining soil particles, and geonets when high-volume in-plane fluid or gas drainage is required.

- Site Conditions: Engineers must consider slope, soil type, groundwater levels, chemical exposure, and load-bearing requirements. These factors influence material selection to ensure long-term performance and stability.

Proper selection maximizes system efficiency, prevents clogging, and enhances durability, especially when using geonet and geotextile in combination for engineered drainage or filtration applications.

Are there performance standards for geonets and geotextiles?

Yes. Both materials are subject to strict industry testing and classification. For example:

- Geonets are tested for in-plane flow rate under pressure (ASTM D4716).

- Geotextiles are evaluated for permittivity, puncture resistance, and tensile strength (ASTM D4491, D4632, etc.).

- High-quality geonets must maintain at least 70% of their initial flow capacity after 10,000 hours of compressive loading.

- — Source: ASTM and ISO Geosynthetics Standards Review, 2024

Specifiers must ensure compatibility with soil type, chemical exposure, and expected mechanical loads.

In conclusion, knowing the distinction between geonet vs geotextile allows engineers to design more efficient and durable systems. Whether used individually or in tandem, these geosynthetics are key components in sustainable infrastructure design.

Geonet vs geotextile comparisons will continue to shape best practices across geotechnical applications.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)