+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Geotechnical fabric, often referred to as geotextile, is a groundbreaking material that is reshaping the landscape of civil engineering and environmental management. This versatile fabric is not just about enhancing the mechanical and structural integrity of engineering projects but also offers significant environmental benefits. Through this article, we will delve into what geotechnical fabric is, its applications, purposes, and its environmental footprint, providing a comprehensive look at this innovative material.

What is Geotechnical Fabric?

Geotechnical fabric, also known as geotextile fabric, is a permeable textile material used in various civil engineering and construction applications. It serves a range of purposes, such as soil stabilization, reinforcement, and erosion control. Here’s a breakdown of its key aspects:

Definition of Geotechnical Fabric

Geotechnical fabric is a synthetic material designed to improve soil properties or perform specific functions in engineering projects. Made from polymers such as polypropylene or polyester, it is typically woven, knitted, or nonwoven.

Key Properties of Geotechnical Fabric

- Permeability: Allows water to pass through while filtering soil particles.

- Durability: Resistant to abrasion, chemicals, and UV degradation.

- Strength: Provides mechanical support for soil stabilization and reinforcement.

- Flexibility: Easy to install and adapt to different soil types and conditions.

Materials Used

- Polypropylene (PP): Commonly used due to its chemical stability, strength, and resistance to environmental factors.

- Polyester (PET): Known for its high tensile strength and low stretch.

- Nylon: Offers excellent abrasion resistance but is less commonly used due to higher cost.

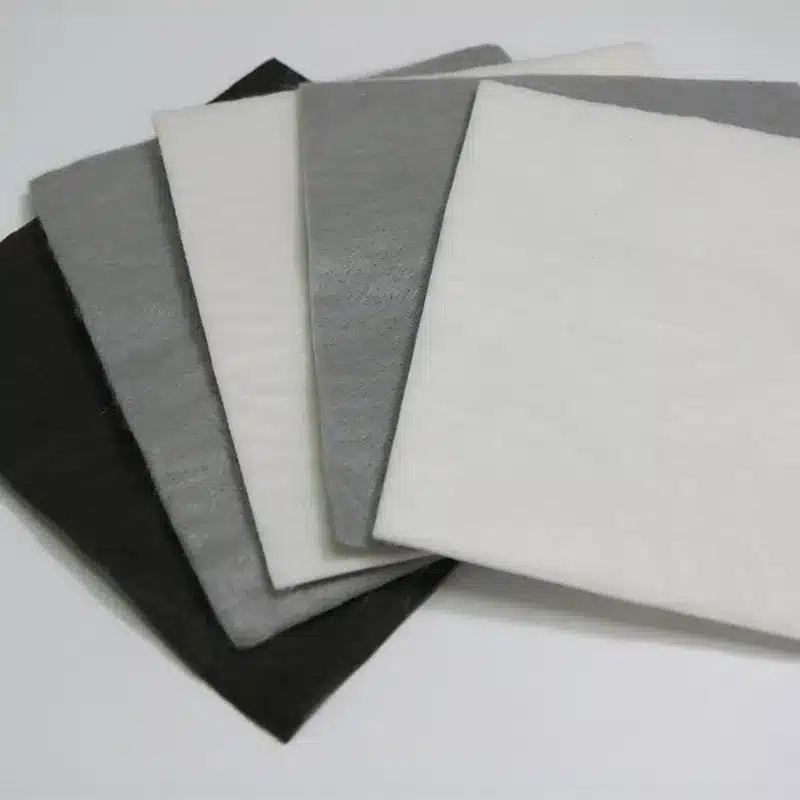

Types of Geotechnical Fabric

- Woven Geotextiles: Made by interlacing threads of fabric. They are ideal for reinforcement and soil stabilization.

- Nonwoven Geotextiles: Produced by bonding fibers together through heat or chemicals. Used for filtration, drainage, and erosion control.

- Knitted Geotextiles: Less common but used in specific applications requiring stretchability and flexibility.

Applications in Civil Engineering

- Soil Stabilization: Geotechnical fabric prevents soil erosion and stabilizes subsoils under roads, embankments, and other structures.

- Erosion Control: Used to protect slopes, banks, and shorelines from water-induced erosion.

- Reinforcement: Improves the strength of weak or unstable soils by providing additional tensile strength.

- Filtration and Drainage: Prevents the migration of soil particles while allowing water to pass through, as seen in foundation systems and retaining walls.

Examples of Geotechnical Fabric in Use

- Road Construction: Geotechnical fabrics are used in base course stabilization to prevent soil mixing and improve road longevity.

- Landfills: Geotextiles are used to filter and separate layers in landfill liners, preventing contamination of groundwater.

- Erosion Control Projects: Coastal and riverbank projects use geotextiles to prevent erosion caused by waves or flowing water.

- Slope Reinforcement: In areas with steep slopes, geotextiles help stabilize the soil, preventing landslides.

Benefits of Using Geotechnical Fabric

- Cost-Effective: Geotechnical fabric is a low-cost solution compared to other methods of stabilization and erosion control.

- Durability: It increases the lifespan of engineering projects by enhancing soil strength and reducing the impact of weathering.

- Environmentally Friendly: By controlling erosion and improving soil retention, geotechnical fabric can reduce sedimentation in water bodies.

- Versatility: It can be used in various conditions and applications, making it highly adaptable.

In summary, geotechnical fabric plays a critical role in improving the performance of soils in construction projects, contributing to soil stabilization, erosion control, and reinforcement. It provides a cost-effective and sustainable solution for numerous civil engineering challenges.

How to Use Geotechnical Fabric?

Geotechnical fabrics, often referred to as geotextiles, are engineered materials used in civil engineering and construction projects for a variety of purposes. These fabrics are commonly employed to enhance the performance of soils, increase the lifespan of infrastructure, and reduce environmental impact. Here’s a comprehensive guide on their applications, types, installation, and best practices:

Introduction to Geotechnical Fabrics

Geotechnical fabrics are synthetic or natural materials designed to serve in a variety of engineering applications, including erosion control, drainage, filtration, and soil stabilization. Made from polymers such as polypropylene or polyester, these fabrics are woven, non-woven, or knitted to provide different properties suited to specific engineering needs.

Types of Geotechnical Fabrics

- Woven Geotextiles: These are made by weaving threads together. They offer high tensile strength and are commonly used for soil stabilization, reinforcement, and road construction.

- Non-Woven Geotextiles: These are made by bonding fibers together without weaving, providing excellent filtration and drainage properties. They are used in applications like erosion control, drainage systems, and landfill liners.

- Knitted Geotextiles: These are made by interlocking yarns, offering stretchability and strength for specific applications like coastal protection or embankment reinforcement.

Key Applications and Benefits

- Erosion Control: Geotechnical fabrics help stabilize soil, preventing erosion on slopes, riverbanks, and other areas prone to soil displacement. They allow water to flow through while retaining soil particles, reducing the risk of landslides and surface erosion.

- Drainage Systems: These fabrics improve water drainage by separating soil from gravel or other drainage materials. They are commonly used in road construction, stormwater management, and agricultural applications.

- Soil Stabilization: Geotechnical fabrics enhance soil strength by providing reinforcement. This is particularly useful in constructing foundations for roads, pavements, and embankments.

- Filtration and Separation: In geotechnical applications, fabrics are often used to filter out fine particles from water or soil, promoting the effective flow of water while preventing soil clogging.

Installation Guidelines

The installation process for geotechnical fabrics depends on the type of project, but the general steps are as follows:

- Step 1: Site Preparation: Clear the installation area of any large debris, sharp objects, or vegetation that may damage the fabric.

- Step 2: Fabric Placement: Unroll the fabric in the direction of the slope or flow. Overlap edges by at least 6 inches to ensure complete coverage. Make sure the fabric lies flat against the surface without wrinkles.

- Step 3: Anchoring the Fabric: Secure the fabric in place using stakes or anchors. In some cases, fabric may need to be buried beneath soil or gravel to ensure stability.

- Step 4: Covering the Fabric: If required, cover the fabric with soil, gravel, or other materials to protect it from UV rays, physical damage, or exposure to the elements.

Best Practices and Common Pitfalls

- Best Practices: Always check for compatibility between the fabric type and the project requirements. Ensure the fabric is installed without folds or wrinkles to avoid reducing its efficiency. Use geotextile-specific anchors or staples to prevent fabric displacement.

- Common Pitfalls: Avoid using a fabric with too low tensile strength for high-stress areas. Do not allow geotextile fabric to be exposed to UV light for long periods without protection, as this can degrade the material. Ensure proper overlap of fabric layers to prevent soil from washing through.

Geotechnical fabrics are versatile and essential tools in civil engineering projects, offering significant benefits in erosion control, drainage, and soil stabilization. By understanding the different types of fabrics, their properties, and proper installation methods, engineers and construction professionals can maximize the efficiency of these materials. Proper planning, installation, and maintenance will help prevent common mistakes and enhance the longevity of the infrastructure.

What is the Purpose of Geofabric?

The main purpose of geofabric is to enhance the durability and stability of earth-based projects. It achieves this by providing separation between different soil layers, improving soil strength, facilitating moisture movement within the soil, and preventing soil erosion. Geofabric is particularly crucial in areas with soft soils that are susceptible to erosion and degradation, thereby extending the life and safety of the structures built upon them.

Is Geotextile Eco-Friendly?

Geotextiles contribute to environmental sustainability in several ways. They reduce the need for traditional construction materials like aggregate and sand, which in turn decreases quarrying and mining activities. Geotextiles are also durable, reducing the frequency of replacements and the associated environmental impact. Moreover, the use of geotextiles in erosion control and sediment management helps protect natural habitats. While they are made from synthetic materials, the overall benefit to the environment from their application often outweighs this factor.

Geotechnical fabric is a transformative material in the engineering and construction fields, offering robust solutions for stabilization, filtration, and erosion control. Its application not only supports structural integrity but also promotes ecological sustainability. As industries continue to seek environmentally friendly solutions, geotechnical fabric stands out as a key player in achieving these goals. With its versatile applications and sustainability benefits, geotechnical fabric is indeed paving the way for a more stable and sustainable future in construction and environmental management.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)