+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

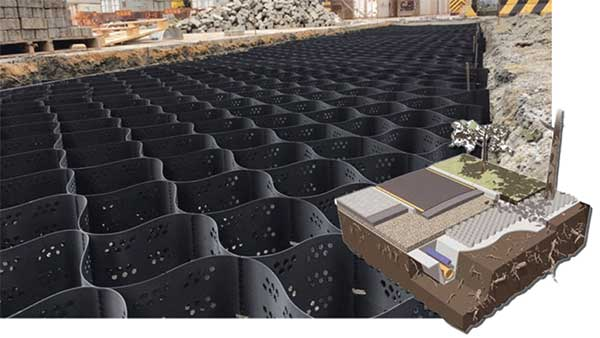

In recent years, HDPE geocell has become a cornerstone solution in modern geotechnical engineering, providing reliable soil stabilization, slope protection, and load-bearing enhancement. This advanced geosynthetic material, made from high-density polyethylene, forms a three-dimensional honeycomb structure that confines and reinforces soil, reducing erosion and improving long-term stability across a range of infrastructure projects. Learn more about geocell materials and applications on Geofantex Geocell Solutions.

What Is HDPE Geocell and How Does It Work?

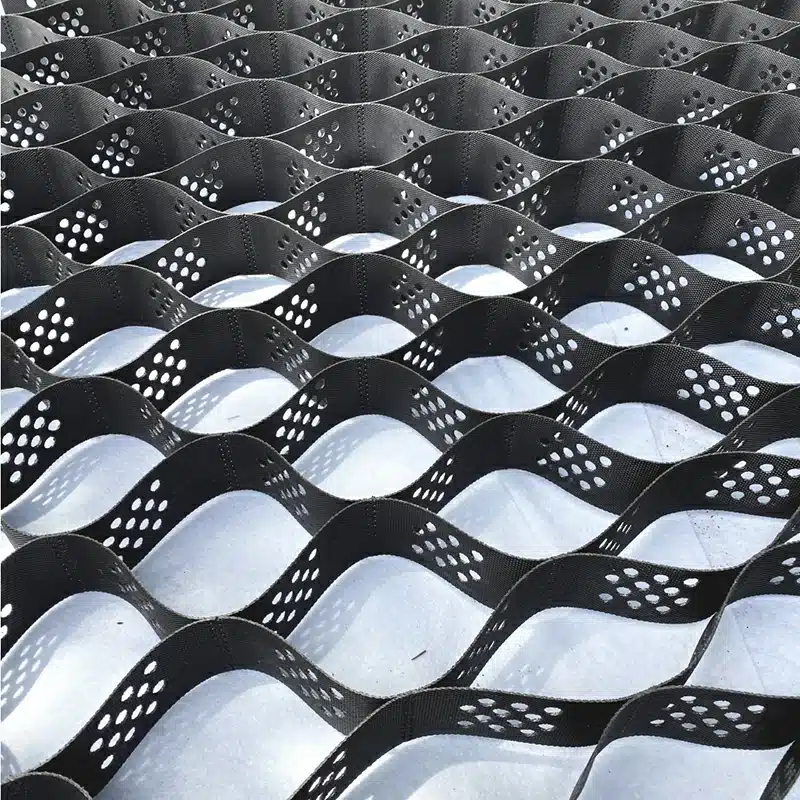

HDPE geocell is a three-dimensional geosynthetic material made from high-density polyethylene. It forms a honeycomb cellular structure that expands on-site and confines soil, aggregate, or other infill materials. This confinement increases stiffness, reduces lateral movement, and significantly improves load distribution.

How it works:

- Soil Confinement: The honeycomb cells prevent soil displacement, improving stability on weak subgrades.

- Load Distribution: Vertical and horizontal stresses are spread evenly, reducing deformation and rutting.

- Erosion Control: Slopes, embankments, and channels gain enhanced protection against wind, rainfall, and water flow.

- Versatile Infill Options: Works with sand, gravel, recycled materials, and even vegetated soil for eco-friendly designs.

- Durable Material: HDPE provides exceptional resistance to chemicals, UV exposure, and long-term weathering.

HDPE geocell is widely used in road reinforcement, slope protection, retaining structures, and ground improvement, offering a lightweight, sustainable alternative to traditional construction methods. For detailed applications, visit Geofantex Geocell Solutions.

Real-World Case Studies

Case 1: Highway Embankment Stabilization in India

In the construction of a major expressway in Maharashtra, engineers faced challenges with weak, silty soil that caused differential settlement and frequent maintenance. The design team implemented a 200 mm layer of HDPE geocell beneath the pavement base. The result was a 25% reduction in aggregate use and a 40% improvement in load distribution. After five years of service, the section reinforced with geocells shows no signs of rutting or surface cracks.

Case 2: Slope Protection for Coastal Roads in the Philippines

Frequent typhoons and coastal erosion threatened a newly developed road section along the shoreline of Cebu. By installing HDPE geocell slope protection systems, filled with locally sourced sand and gravel, the slope was effectively stabilized. Vegetation was later established within the geocell structure, providing both functional and aesthetic benefits. The solution reduced wave-induced erosion by over 60% and required minimal maintenance over the following three years.

Case 3: Railway Track Bed Reinforcement in South Africa

A rail company sought to extend its freight line over soft clay subgrades. The geotechnical team utilized HDPE geocell layers under the ballast to improve load-bearing capacity and drainage. The outcome was a significant reduction in track settlement, extending maintenance intervals by nearly double compared to conventional methods.

Key Takeaways

These cases highlight how HDPE geocell applications improve structural integrity, reduce environmental impact, and cut overall project costs. From highways and railways to slope and erosion control, geocell technology continues to demonstrate its adaptability and long-term value in geotechnical engineering. For more sustainable engineering materials, visit Geofantex Geosynthetics.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)