+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

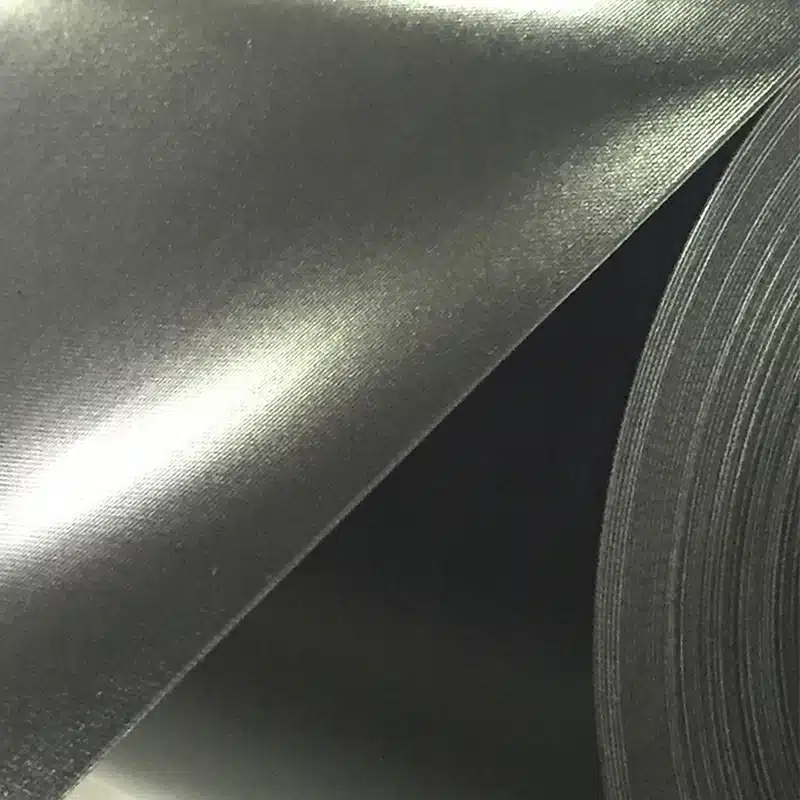

HDPE geomembranes, a type of geomembrane made from high-density polyethylene, are widely used in various industrial and environmental applications. These synthetic membranes act as barriers, preventing the movement of fluids or gases, making them essential for projects involving waste containment, water conservation, and environmental protection. In this article, we will explore the differences between HDPE geomembranes and other types of geomembranes, as well as the various types available, to understand their benefits and applications.

What is the difference between geomembrane and HDPE?

To provide a clear comparison between geomembranes and high-density polyethylene (HDPE), let’s break it down into key sections:

Definition and Composition

- Geomembrane: A geomembrane is a synthetic, impermeable membrane used in geotechnical and environmental engineering applications to control the movement of liquids or gases. It is often made from various polymers, such as polyethylene, PVC, or polypropylene. The material is designed for applications like lining landfills, ponds, or reservoirs.

- HDPE (High-Density Polyethylene): HDPE is a specific type of polyethylene plastic with a high density, making it stronger and more rigid compared to low-density polyethylene (LDPE). It is made from polymerizing ethylene monomers and is recognized for its toughness and resistance to chemicals. HDPE is commonly used for applications like pipes, containers, and geomembranes.

Physical and Chemical Properties

- Geomembrane Properties: Impermeable to liquids and gases. Can be made from various polymers such as PVC, LDPE, or HDPE. Available in a variety of thicknesses, typically ranging from 0.5mm to several millimeters. Flexible and can conform to various land surfaces.

- HDPE Properties: High tensile strength and impact resistance. Low moisture absorption and good chemical resistance, especially to acids, alkalis, and organic solvents. Strong but lightweight, making it easy to handle. Good UV resistance but may require additives for long-term exposure to sunlight.

Common Uses

- Geomembranes: Used in construction for lining waste containment systems (landfills), reservoirs, and lagoons. Applied in water and wastewater treatment, mining (e.g., heap leach pads), and in agricultural applications. Used in environmental containment (such as controlling hazardous waste sites).

- HDPE: Used in water and gas distribution pipes, containers, and bottles. Applied in the manufacturing of geomembranes (HDPE geomembranes). Used in packaging, textiles (ropes), and in construction for drainage systems.

Advantages and Disadvantages

- Geomembranes:

- Advantages:

- Flexible and can be adapted to different project needs.

- Provides long-term durability for containment applications.

- High resistance to chemicals and UV rays (depending on material).

- Disadvantages:

- Can be expensive to install and maintain.

- Performance can be compromised if not installed correctly, leading to leaks.

- HDPE:

- Advantages:

- Strong, durable, and cost-effective.

- High chemical resistance and low permeability.

- Environmentally friendly, as it is recyclable.

- Disadvantages:

- May degrade under prolonged UV exposure unless properly stabilized.

- Can be difficult to weld or seal compared to other materials like PVC.

Performance Characteristics

- Geomembrane Durability: Geomembranes made from HDPE are known for their longevity and durability in various environmental conditions. They are highly resistant to chemicals, UV rays, and mechanical stress, making them ideal for long-term containment.

- HDPE Durability: HDPE is renowned for its resistance to impact, wear, and chemical degradation. It maintains its properties under harsh conditions, though exposure to UV radiation can cause brittleness unless additives are used to protect it from the sun.

Summary Comparison

| Property/Aspect | Geomembranes | HDPE |

|---|---|---|

| Definition | Synthetic impermeable membranes | Type of polyethylene plastic |

| Composition | Varies (HDPE, PVC, etc.) | Pure HDPE polymer |

| Common Uses | Waste containment, water barriers | Pipes, containers, geomembranes |

| Chemical Resistance | High (depends on material) | Very high (acid, alkalis, etc.) |

| Flexibility | Flexible | Stiff but can be flexible in thin forms |

| UV Resistance | Varies (HDPE better) | Good (with additives) |

What are the three types of geomembranes?

Geomembranes are synthetic liners used primarily in environmental and geotechnical applications to prevent leakage or contamination of soil or water. The three primary types of geomembranes are:

High-Density Polyethylene (HDPE) Geomembranes

- Material Composition: HDPE geomembranes are made from a thermoplastic polymer with a high-density structure.

- Common Uses: They are widely used in landfills, waste containment, and water reservoirs.

- Advantages: High chemical resistance, making them suitable for use in harsh environments. Durability and resistance to UV degradation. Excellent barrier properties against liquids and gases.

- Notable Characteristics: Strong and resistant to punctures. Can be welded easily, providing strong seams. Industry standards: ASTM D4437 and GRI-GM13.

Polyvinyl Chloride (PVC) Geomembranes

Material Composition: PVC geomembranes are made from a plasticized form of PVC, which allows for flexibility.

Common Uses: PVC geomembranes are commonly used in applications like pond liners, canals, and waste containment in less extreme environments.

Advantages:

- High flexibility, which makes them easier to install in complex shapes.

- Good resistance to chemicals, though not as robust as HDPE.

- Lower cost compared to HDPE.

Notable Characteristics: - Can be welded and heat-sealed.

- Better suited for lower-stress applications where flexibility is required.

- Industry standards: ASTM D7176 and GRI-GM17.

Ethylene Propylene Diene Monomer (EPDM) Geomembranes

Material Composition: EPDM geomembranes are made from a synthetic rubber polymer that provides excellent resistance to weathering, ozone, and UV radiation.

Common Uses: They are often used for roofing, ponds, and wastewater treatment facilities.

Advantages:

- Excellent weathering and UV resistance.

- Superior flexibility at low temperatures, making them ideal for cold climates.

- Long lifespan with minimal maintenance.

Notable Characteristics:

- Can be fabricated into custom shapes.

- Low permeability to water and chemicals.

- Industry standards: ASTM D4632 and GRI-GM25.

These geomembranes are used in various applications based on their material properties, performance under environmental conditions, and cost-effectiveness. The choice of geomembrane depends on factors such as environmental exposure, chemical resistance requirements, and flexibility needs.

What is HDPE geomembrane material?

HDPE geomembrane material is a synthetic polymer made from high-density polyethylene, crafted from high-quality resins, thoroughly tested, and comprising approximately 97.5% polymer, along with 2.5% Carbon Black, antioxidants, and thermal stabilizers. It is widely recognized for its excellent chemical resistance, high durability, and flexibility in industrial applications. HDPE is specifically engineered to withstand harsh environments, making it ideal for use in landfills, mining operations, wastewater treatment plants, and environmental protection projects. Its non-toxic, environmentally friendly properties also contribute to its widespread use in the containment of hazardous materials and the conservation of natural resources like water.

What are the different types of geomembrane liners?

There are several types of geomembrane liners, each designed to meet specific project needs:

| HDPE Liners | The most common type, offering high durability and chemical resistance. They are suitable for large-scale projects like landfills and ponds. |

| LLDPE (Linear Low-Density Polyethylene) Liners | More flexible than HDPE, LLDPE is used where contour adaptability is needed, such as in irrigation ponds or channels. |

| PVC Liners | These liners are flexible and ideal for smaller, more intricate containment systems like decorative ponds or small water features. |

| EPDM Liners | Known for their extreme flexibility and elasticity, EPDM liners are used in projects requiring the liner to stretch or accommodate ground shifts. |

HDPE geomembranes are a critical solution for projects requiring strong, durable, and chemically resistant liners. Understanding the differences between HDPE and other geomembranes helps in selecting the right material for specific environmental or industrial applications. With a range of geomembrane types, including HDPE, PVC, and EPDM, each offering unique benefits, these liners play a vital role in fluid and gas containment, environmental protection, and resource conservation.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)