+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

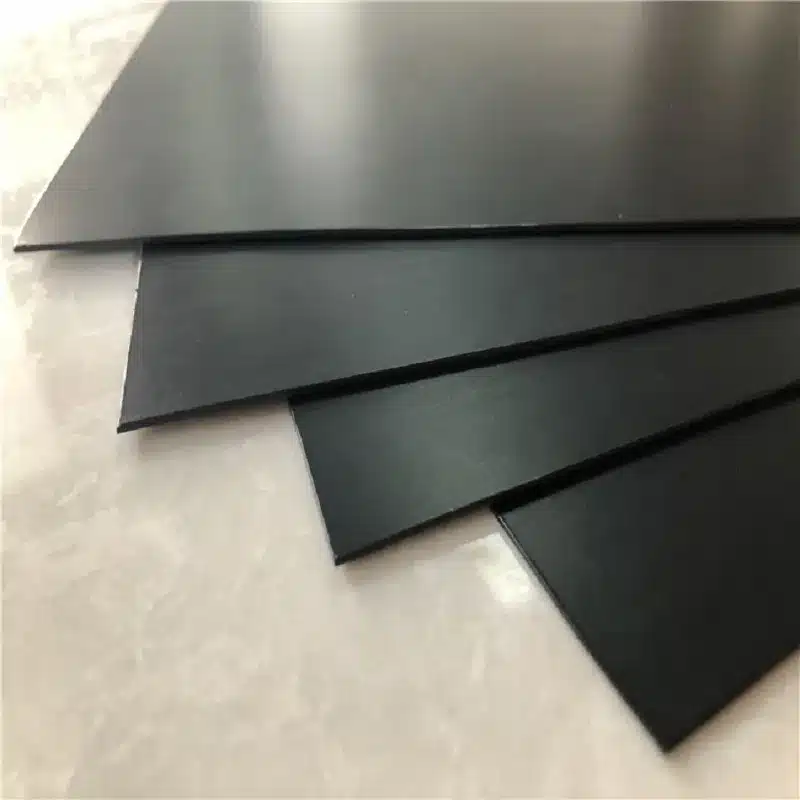

Geomembranes are synthetic membranes used to control fluid or gas migration in a variety of applications, such as environmental, civil, and hydraulic engineering projects. Among the different materials used for geomembranes, polypropylene film stands out due to its durability, flexibility, and chemical resistance. This article delves into the world of geomembranes, focusing on the properties and applications of polypropylene film.

What are the three types of geomembranes?

- High-Density Polyethylene (HDPE): HDPE geomembranes, alongside PVC-P and EPDM, are known for their high strength-to-density ratio, making them ideal for applications requiring durability and puncture resistance. They are widely used in landfill liners, mining, and water containment projects.

- Low-Density Polyethylene (LDPE): LDPE geomembranes, though not as robust as HDPE or PVC-P, are more flexible and easier to install, especially in complex terrains. They are commonly used in agricultural ponds, canals, and decorative water features, where ease of installation is a priority.

- Polypropylene (PP): Polypropylene geomembranes, particularly those made from polypropylene film, offer excellent chemical resistance and flexibility, similar to HDPE and EPDM. They are used in applications where chemical exposure and dynamic movement are expected, such as waste containment, sewage treatment plants, and industrial lagoons.

What does geomembrane liner do?

A geomembrane liner acts as a barrier to prevent the seepage of fluids and gases. This barrier function is crucial in a variety of applications:

- Environmental Protection: Geomembrane liners are used to contain hazardous materials, preventing them from contaminating the surrounding soil and groundwater.

- Water Conservation: They line canals, reservoirs, and ponds to minimize water loss due to seepage.

- Agricultural Use: Geomembranes prevent fertilizers and pesticides from leaching into the soil, ensuring they remain effective and reducing environmental impact.

- Industrial Applications: Geomembrane liners play a key role in the construction of brine evaporation ponds, serving as a barrier to prevent loss of the precious slurry.

When to use geomembrane?

Geomembranes should be used in any situation where fluid or gas containment is critical, acting as barriers to moisture and gas flow. Some common scenarios include:

- Landfills: To contain leachate and prevent it from contaminating groundwater.

- Mining Operations: To contain tailings and other hazardous by-products.

- Agriculture: For lining ponds and irrigation canals to conserve water.

- Industrial Sites: To line containment ponds and prevent industrial chemicals from leaking into the environment.

What is the most widely used geomembrane in current use?

High-Density Polyethylene (HDPE) is the most widely used geomembrane due to its high durability, chemical resistance, and cost-effectiveness. HDPE membranes are particularly robust, making them suitable for large-scale applications such as landfills, mining, and water containment. However, polypropylene film is gaining popularity in specific applications where flexibility and resistance to chemical degradation are paramount.

Geomembranes play a vital role in environmental protection and resource management by providing a reliable barrier against fluid and gas seepage. Among the various types, polypropylene film geomembranes offer exceptional flexibility and chemical resistance, making them ideal for dynamic and chemically aggressive environments. Understanding the types and applications of geomembranes can help in selecting the right material for specific needs, ensuring optimal performance and longevity.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)