+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

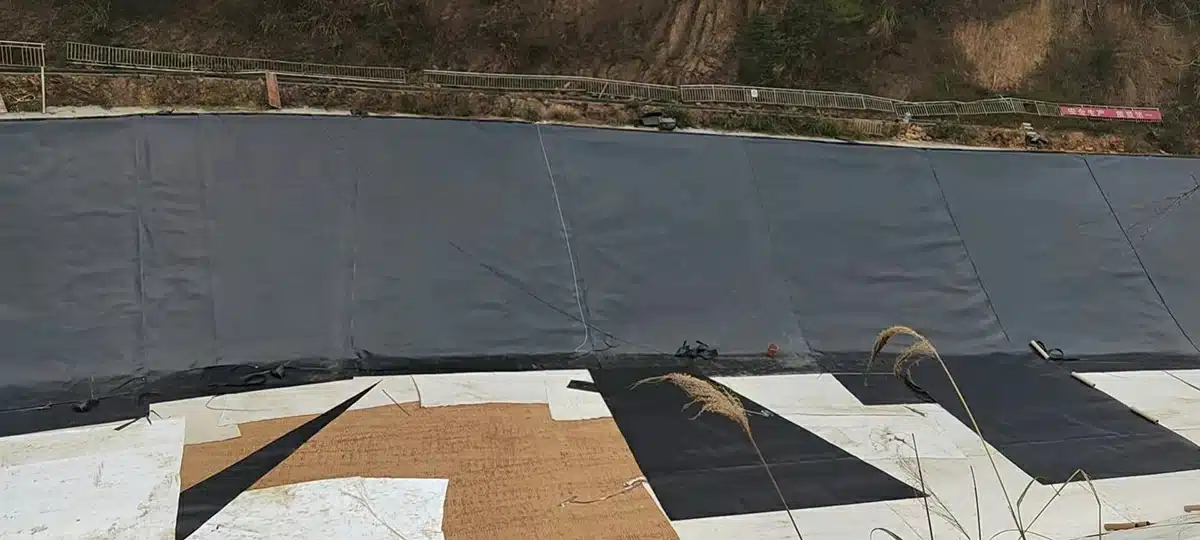

High-density polyethylene (HDPE) geomembranes have become the cornerstone of modern aquatic engineering, offering an unparalleled solution for the waterproofing and protection of man-made ponds and water containment structures. These specialized pond liners are crafted from a premium grade of plastic, known for their robustness, resistance to chemicals, and environmental durability. This article dives into the core of HDPE geomembrane pond liners, unraveling their waterproof capabilities, distinguishing features from other geomembranes, comparing them with PVC alternatives, and determining whether HDPE or LDPE liners are superior for pond applications.

Is Geomembrane Waterproof?

Geomembranes are synthetic liners made from materials like HDPE, LLDPE, PVC, or EPDM, designed specifically to prevent fluid migration. They are widely used in applications such as:

- Landfill liners

- Pond and reservoir linings

- Mining and industrial containment

- Canal and tunnel waterproofing

Their low permeability makes them highly effective barriers against water, leachate, and other liquids. However, their waterproofing performance depends on proper installation, welding, and quality control to avoid leaks or punctures.

What is the Difference Between an HDPE Liner and a Geomembrane?

The key difference between an HDPE liner and a geomembrane lies in their definitions and materials:

- HDPE Liner: A specific type of geomembrane made from high-density polyethylene (HDPE). It is widely used for containment applications like landfills, ponds, and reservoirs due to its high chemical resistance, durability, and low permeability.

- Geomembrane: A broader term that refers to any synthetic membrane used as a barrier for fluid or gas containment. It can be made from various materials, including HDPE, LLDPE (Linear Low-Density Polyethylene), PVC, EPDM, and polypropylene.

What is the Difference Between PVC and HDPE Geomembrane?

The primary differences between PVC (Polyvinyl Chloride) geomembranes and HDPE (High-Density Polyethylene) geomembranes are based on their material properties, flexibility, durability, and application suitability. Here’s a breakdown:

| PVC Geomembrane | HDPE Geomembrane | |

| Material Composition & Flexibility | Made from polyvinyl chloride, PVC geomembranes are highly flexible due to plasticizers added to the material. This flexibility allows for easier installation and better conformity to uneven surfaces. | Made from high-density polyethylene, HDPE is more rigid compared to PVC. It requires specialized equipment for installation due to its stiffness. |

| Chemical Resistance & Durability | Offers good chemical resistance but is more vulnerable to UV exposure and weathering over time. The plasticizers in PVC can leach out, causing the material to become brittle. | Excellent chemical resistance, particularly against acids, solvents, and aggressive chemicals. It is highly resistant to UV radiation and has a longer lifespan in outdoor applications. |

| Seam Strength & Installation | Seams are usually bonded using adhesives or thermal fusion, making installation relatively easy but slightly weaker compared to HDPE. | Uses heat welding to create strong, leak-proof seams. However, it requires precise installation techniques and skilled labor. |

| Lifespan & Environmental Impact | Typically has a shorter lifespan, especially in exposed conditions, due to plasticizer loss and UV degradation. | Has a longer lifespan (often exceeding 50 years in certain conditions) and is more environmentally stable due to its resistance to chemical leaching. |

| Applications | Commonly used in applications requiring flexibility, such as temporary liners, landfill covers, and wastewater treatment lagoons. | Preferred for long-term containment solutions like landfill liners, mining operations, and industrial waste containment due to its superior durability. |

If flexibility and ease of installation are the priority, PVC is a good choice. If durability, chemical resistance, and longevity are more critical, HDPE is the better option.

Which is Best for Pond Liner: HDPE or LDPE?

When choosing between HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene) for pond liners, HDPE is generally the better choice. Here’s why:

- Durability: HDPE is much stronger and more durable than LDPE. It’s resistant to punctures, UV degradation, and chemicals, which makes it ideal for outdoor use in ponds where the liner is exposed to varying conditions.

- Longevity: HDPE has a longer lifespan, often lasting several decades without significant degradation, while LDPE tends to break down more quickly under UV light exposure.

- Thickness: HDPE is usually thicker and can withstand the weight of the water and any pressure without tearing or stretching, making it a more reliable option for a pond liner.

- Environmental Resistance: HDPE is better at withstanding environmental stressors like temperature fluctuations, while LDPE is more flexible but less resistant to such conditions.

- Cost: LDPE is usually less expensive, but the long-term durability of HDPE often makes it a better investment.

So, while LDPE might be suitable for smaller, less demanding applications, HDPE is typically preferred for ponds due to its superior strength and longevity.

HDPE geomembrane pond liners stand out as the pinnacle of waterproofing technology in the realm of aquatic engineering, offering unmatched durability, chemical resistance, and environmental protection. Whether compared to other geomembranes like PVC or debating between HDPE and LDPE for specific applications, HDPE liners consistently emerge as the top choice for those seeking long-term performance and sustainability. As we continue to push the boundaries of water conservation and environmental protection, HDPE geomembranes will undoubtedly play a pivotal role in shaping the future of pond liner technology.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)