+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

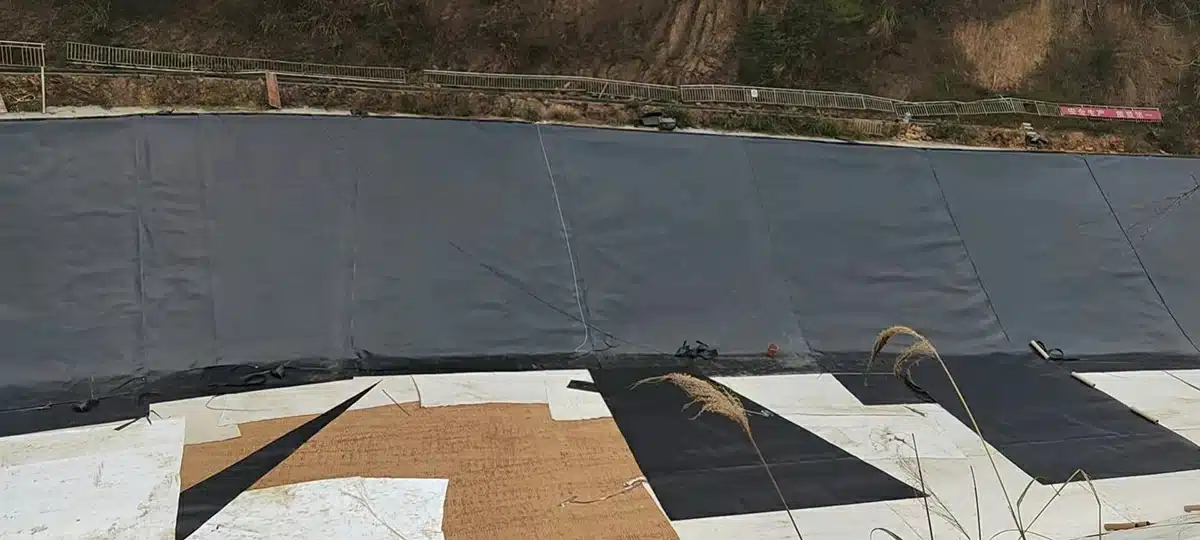

Geomembrane materials, including EPDM (Ethylene Propylene Diene Monomer), Linear Low-Density Polyethylene (LLDPE), High-Density Polyethylene (HDPE), Polyvinyl Chloride (PVC), and Polypropylene (PP), are revolutionizing the way we protect our environment. These synthetic polymers act as robust barriers to prevent the mix of liquids in landfill sites, ponds, and other critical areas, underscoring their pivotal role in environmental conservation and engineering projects. Delving into the composition, which spans from the highly flexible EPDM, known for its weather resistance, to the sturdy and chemically resistant HDPE and LLDPE, this article provides insights into why these materials are considered an indispensable part of modern environmental and engineering solutions. Additionally, the inclusion of PVC and PP expands the versatility of geomembranes, catering to a wide range of applications due to their distinct properties, such as PVC’s affordability and PP’s fatigue resistance.

What is Geomembrane Made Of?

Geomembranes are impermeable membranes used widely for waste containment, water storage, and other environmental protection applications. Here is a detailed explanation of the materials used in their production and their properties:

Materials Used in Geomembranes

High-Density Polyethylene (HDPE):

- Properties: HDPE is known for its high strength-to-density ratio, chemical resistance, and UV resistance. It is flexible, durable, and provides an excellent barrier against contaminants.

- Applications: Commonly used in landfill liners, mining operations, and water containment projects.

Low-Density Polyethylene (LDPE) and Linear Low-Density Polyethylene (LLDPE):

- Properties: These materials are more flexible than HDPE, making them suitable for applications requiring more pliability. They also offer good chemical resistance.

- Applications: Used in various containment applications where flexibility is key, such as small pond liners and covers.

Polyvinyl Chloride (PVC):

- Properties: PVC geomembranes are highly flexible, easy to install, and have good tensile strength. They also provide excellent resistance to many chemicals.

- Applications: Suitable for applications requiring intricate shapes and fittings, such as canals, ponds, and industrial waste containment.

Ethylene Propylene Diene Monomer (EPDM):

- Properties: EPDM is highly flexible, even in low temperatures, and offers excellent resistance to UV radiation and weathering.

- Applications: Often used in applications requiring significant flexibility and durability, like decorative ponds and reservoirs.

Bituminous Geomembrane (BGM):

- Properties: BGM is composed of a reinforced layer of non-woven geotextile impregnated with a bituminous mix. It is highly resistant to punctures and chemical attacks.

- Applications: Ideal for containment of aggressive chemicals, waste storage, and in areas with potential mechanical damage.

Geomembranes are made from various polymers, each offering unique properties that cater to specific applications. The choice of material depends on the specific requirements of the project, including the need for flexibility, chemical resistance, and durability.

What is the Raw Material for Geomembrane?

Raw Material for Geomembrane Production

Primary Material:

- High-Density Polyethylene (HDPE):

- Description: HDPE is the most commonly used material for geomembranes.

- Properties: High tensile strength, chemical resistance, and durability.

Additional Materials:

- Low-Density Polyethylene (LDPE):

- Description: Used for specific applications requiring more flexibility.

- Properties: Higher flexibility, and lower tensile strength compared to HDPE.

- Linear Low-Density Polyethylene (LLDPE):

- Description: Offers a balance between HDPE and LDPE properties.

- Properties: Good flexibility, and moderate tensile strength.

- Polyvinyl Chloride (PVC):

- Description: Used in applications where flexibility is a key requirement.

- Properties: Excellent flexibility, and good chemical resistance.

- Ethylene Propylene Diene Monomer (EPDM):

- Description: A synthetic rubber used for its elasticity and UV resistance.

- Properties: High elasticity, excellent UV and weather resistance.

Primary Components and Properties:

- Polymeric Resin: The base material providing the essential properties of the geomembrane.

- Carbon Black: Added for UV resistance and durability.

- Antioxidants: Enhance longevity by preventing oxidation.

- Plasticizers (in PVC): Improve flexibility and workability.

- Fillers and Stabilizers: Enhance specific properties such as strength, flexibility, and resistance to environmental factors.

Applications:

- Environmental Protection: Landfill liners, wastewater treatment lagoons.

- Water Management: Ponds, reservoirs, and canals.

- Mining: Heap leach pads, tailings ponds.

Why is Geomembrane Important?

Geomembranes are synthetic membranes used across various industries due to their crucial functions and benefits. Here’s a structured explanation of their importance:

Containment and Barrier:

- Landfills: Geomembranes act as liners to prevent leachate from contaminating groundwater.

- Mining: Used in heap leach pads to contain and control chemicals.

- Water Reservoirs: Ensure water retention and prevent seepage.

- Wastewater Treatment: Contain effluents and prevent environmental contamination.

Protection and Durability:

- Infrastructure Projects: Geomembranes protect foundations from moisture and chemical exposure.

- Environmental Remediation: Used in capping contaminated sites to prevent pollutant migration.

Benefits

- Environmental Protection: Prevents contamination of soil and groundwater by hazardous substances. Aids in sustainable waste management practices. Supports safe water storage and reduces the risk of waterborne diseases.

- Durability: High resistance to chemicals, UV radiation, and physical damage. Long-lasting, reducing the need for frequent replacements and maintenance.

- Cost-Effectiveness: Reduces long-term environmental cleanup costs by preventing contamination. Decreases maintenance costs due to their durability and reliability. Enhances the efficiency of containment systems, optimizing operational costs.

Geomembranes play a critical role in various sectors by providing reliable containment, enhancing durability, and promoting environmental protection, all while being cost-effective. Their application in projects ranging from landfills to water reservoirs highlights their versatility and importance.

What are the Applications of Geomembrane?

Construction Industry:

- Landfills: Geomembranes are used as liners to prevent leachate from contaminating the surrounding soil and groundwater.

- Reservoirs and Ponds: Used to line reservoirs, ponds, and artificial lakes to prevent water seepage.

- Tunnels and Dams: Applied as waterproofing barriers in tunnels and dams to control water ingress and ensure structural integrity.

Environmental Protection:

- Containment Systems: Employed in hazardous waste containment systems to prevent toxic substances from leaking into the environment.

- Aquaculture: Used in fish and shrimp farming to create a controlled aquatic environment and reduce water loss.

- Mining: Used to line tailings dams and heap leach pads to prevent the contamination of surrounding areas by mining by-products.

Agriculture:

- Irrigation Canals: Used to line irrigation canals to reduce water loss through seepage.

- Waste Storage: Applied in agricultural waste storage facilities to contain animal waste and prevent groundwater contamination.

- The lining of Silage Pits: Utilized to create a barrier that prevents the leachate from silage from contaminating the soil and water sources.

Benefits and Advantages:

- Durability: Geomembranes are highly durable and resistant to various environmental conditions.

- Cost-Effective: They provide a cost-effective solution for containment and waterproofing compared to traditional methods.

- Ease of Installation: Geomembranes are relatively easy to install and require less time compared to alternative solutions.

- Versatility: Available in various materials and thicknesses, making them suitable for a wide range of applications.

Challenges and Limitations:

- Damage: Geomembranes can be punctured or damaged during installation or by sharp objects, which may compromise their effectiveness.

- UV Degradation: Prolonged exposure to ultraviolet light can degrade some types of geomembranes, reducing their lifespan.

- Chemical Resistance: Not all geomembranes are resistant to all chemicals, so selecting the appropriate type is crucial for specific applications.

Geomembrane materials represent a crucial advancement in environmental protection and engineering. Made from durable synthetic polymers, these versatile materials offer solutions for safe water conservation, waste containment, and much more. As our awareness and commitment to environmental sustainability grow, the importance and applications of geomembrane materials are set to expand, paving the way for a more sustainable and environmentally responsible future.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)