+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

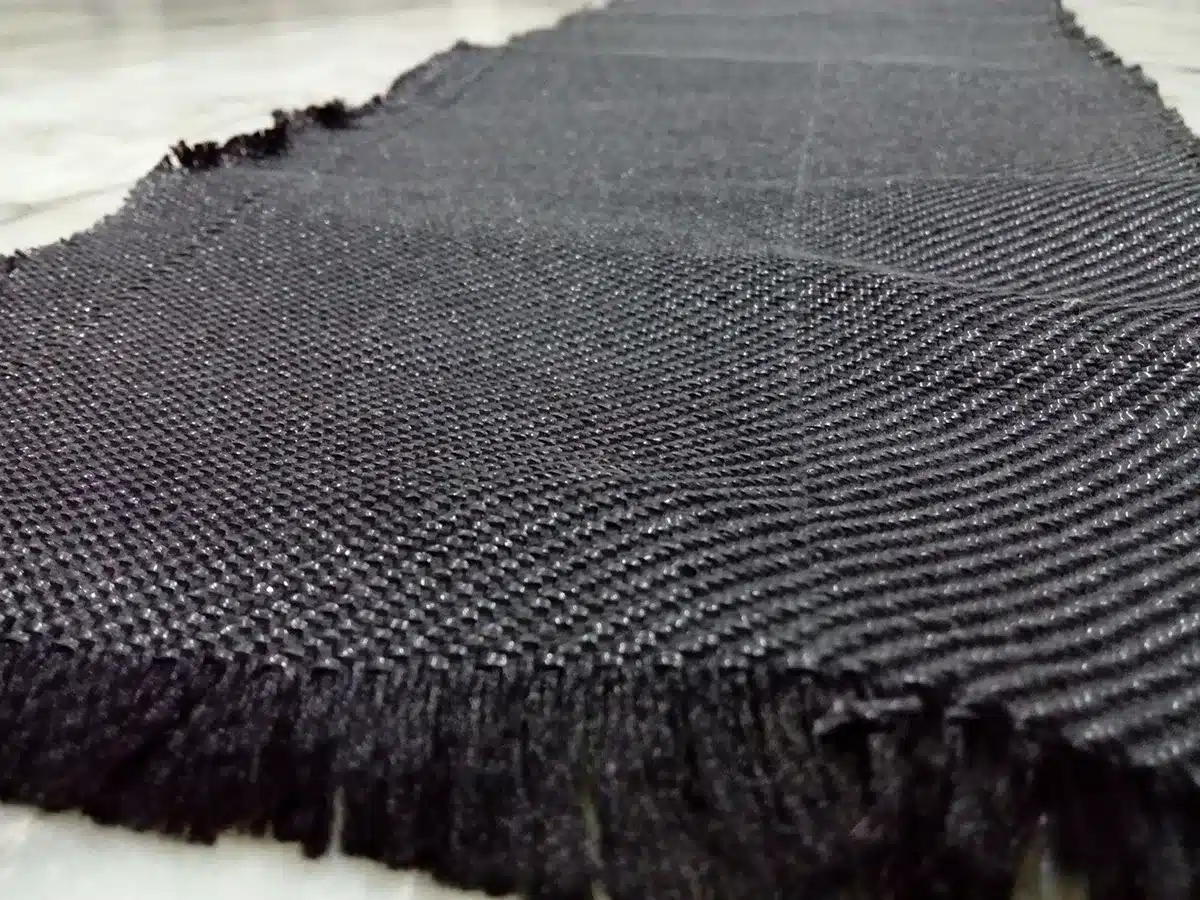

Geotextile fabric stands as a cornerstone in modern infrastructure projects, offering unparalleled strength and resilience. Engineered with robust materials and a higher mass per unit area, this fabric category delivers exceptional reinforcement, ensuring longevity and stability in diverse engineering applications. From road construction to erosion control and beyond, heavyweight geotextile fabric serves as a reliable solution, fortifying structures against intense loads and harsh environmental conditions. Discover how this formidable material elevates the standards of durability and strength in engineering endeavors, ensuring reliability and sustainability in critical infrastructure projects.

What is the strongest geotextile fabric?

- Measurement Units: Typically expressed in grams per square meter (GSM) or ounces per square yard (oz/yd²)

- Threshold: Geotextile fabric above 300 GSM (≈10–12 oz/yd²) are generally classified as heavyweight

- Strength and Durability: Heavyweight geotextiles offer high tensile strength and excellent resistance to tearing, puncture, and abrasion, ensuring long-term performance under heavy loads

- Applications: Commonly used in road base reinforcement, retaining walls, embankments, landfill systems, and subgrade stabilization projects

- Trade-offs: Heavier geotextiles may be less flexible and require more careful handling and installation compared to lighter fabrics

- Performance Advantage: Heavyweight geotextile fabric provide superior load-bearing capacity, structural reinforcement, and durability, making them ideal for demanding civil and environmental engineering applications

What Are the Different Weights of Geotextile Fabric?

Geotextile fabrics are classified by weight, typically measured in grams per square meter (GSM) or ounces per square yard (oz/yd²). Fabric weight directly affects strength, thickness, durability, and suitable applications.

Common Geotextile Fabric Weight Categories

| Weight (gsm) | Approx. Weight (oz/yd²) | Typical Applications |

|---|---|---|

| 80–120 gsm | 2.5–3.5 oz/yd² | Light drainage, filtration, landscaping |

| 120–200 gsm | 3.5–6 oz/yd² | Soil stabilization, erosion control |

| 200–400 gsm | 6–12 oz/yd² | Road base reinforcement, heavy drainage |

| 400–600+ gsm | 12+ oz/yd² | Heavy-duty reinforcement, retaining walls |

How weight affects performance

- Lightweight geotextiles (<150 GSM): Primarily used for filtration and separation where loads are minimal.

- Medium-weight geotextiles (150–300 GSM): Offer a balance of strength and permeability, suitable for stabilization and erosion control.

- Heavyweight geotextiles (300+ GSM): Provide high tensile strength, puncture resistance, and durability for demanding applications such as road construction and structural reinforcement.

Key selection considerations

- Higher weight = greater strength and durability

- Lower weight = better flexibility and ease of installation

- Project load, soil conditions, and drainage requirements should guide final selection

Geotextile fabric weights range from lightweight to heavyweight, each designed for specific engineering needs. Choosing the correct weight ensures optimal performance, cost efficiency, and long-term stability.

How thick is geotextile fabric?

Geotextile fabrics are used in a wide range of applications including construction, landscaping, and environmental projects. The thickness of geotextile fabric varies depending on its type and intended purpose. Below is an overview of the typical thickness ranges for woven and non-woven geotextiles, as well as factors that influence the choice of thickness.

| Filtration, drainage, erosion control, and landfills | Thickness Range (mm) | Typical Applications | Influencing Factors |

|---|---|---|---|

| Woven Geotextile | 0.1 – 0.5 | Reinforcement, stabilization, roadbeds, railways | Load-bearing, soil type |

| Non-Woven Geotextile | 0.5 – 5 | Erosion control, vegetation support, and temporary use | Drainage, soil composition |

| Biodegradable Geotextile | 0.2 – 1 | Erosion control, vegetation support, temporary use | Erosion control, biodegradability |

| Composite Geotextile | 0.3 – 2 | Combined filtration, drainage, reinforcement | Load distribution, drainage, tensile strength |

The choice of thickness depends on project-specific needs such as drainage, load-bearing, and soil conditions. Thicker geotextiles provide more strength and better filtration but may be more expensive, so the ideal thickness is often a balance of these factors.

What fabric weight is considered heavy?

- Measurement Units: typically expressed in grams per square meter (GSM) or ounces per square yard (oz/yd²)

- Threshold: fabrics over 10 oz/yd² (≈280 GSM) are generally considered heavy

- Durability: heavier fabrics resist abrasion, tearing, and wear, offering long-term performance

- Applications: used for high-strength needs such as outdoor gear, upholstery, workwear, and heavy-duty geotextiles

- Trade-offs: heavy fabrics may be less flexible and breathable compared to lighter fabrics

Heavyweight geotextile fabric provide superior strength and resilience, making them ideal for engineering applications that demand durability, load-bearing capacity, and long-lasting stability.

Heavyweight geotextile fabric, with their formidable strength and durability, serve as fundamental components in various engineering projects. Understanding their weight, thickness, and strength characteristics aids engineers and project managers in selecting the most suitable fabric for optimal performance and longevity in their applications.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)