+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

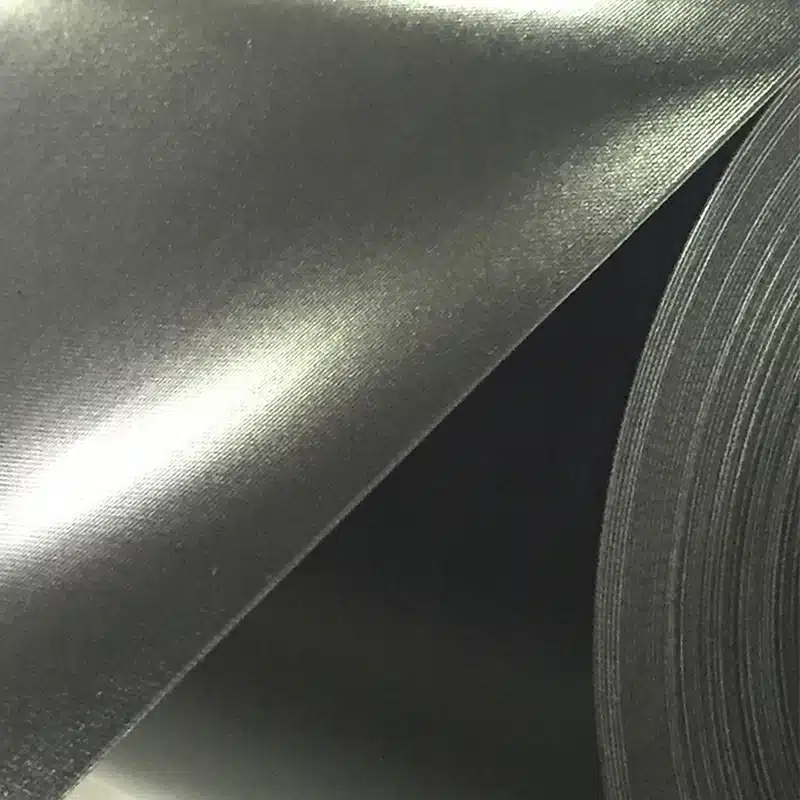

Geomembranes are an essential tool in various engineering and environmental applications, primarily known for their waterproofing capabilities. These synthetic membranes are used to prevent the movement of fluids or gases across a physical barrier, making them invaluable in projects ranging from landfills to ponds. In this article, we will delve into the waterproof nature of geomembranes, how they are sealed, and the specific role of polyethylene in enhancing their waterproofing properties.

Is geomembrane waterproof?

Yes, geomembranes are specifically designed to be waterproof. Made from synthetic materials like polyethylene, PVC, or EPDM, these membranes act as barriers that prevent water, chemicals, and gases from passing through. Geomembranes are one of the most versatile products used in SUDS systems, waterproofing, landfill sites, and below ground drainage containment. Their waterproofing capability is a key reason they are widely used in applications such as landfill liners, pond linings, and containment systems for hazardous materials. Their effectiveness in creating a watertight seal is essential for protecting the environment and ensuring the integrity of engineered systems.

How do you seal a geomembrane?

Sealing a geomembrane is a crucial step in ensuring its waterproof effectiveness. The process typically involves welding the seams of the geomembrane using specialized equipment. There are two common methods for sealing geomembranes:

| Thermal Welding | This heat-welding process uses heat to melt the edges of the geomembrane, which are then pressed together to form a strong, watertight seal. |

| Chemical Welding | In this method, a solvent or adhesive is applied to the edges of the geomembrane to bond them together. |

Both methods are effective, and the choice depends on the type of geomembrane material and the specific application. Proper sealing ensures that the geomembrane maintains its integrity and prevents leaks.

How waterproof is polyethylene?

Polyethylene is a widely used plastic known for its excellent waterproof properties. Here are some key points regarding its waterproof characteristics:

| Water Resistance | Polyethylene is inherently resistant to water, meaning it does not absorb moisture. It acts as an effective barrier against water, making it suitable for applications requiring waterproof materials. |

| Types of Polyethylene | There are different types of polyethylene, such as low-density polyethylene (LDPE) and high-density polyethylene (HDPE). Both types exhibit good waterproofing capabilities, but HDPE is generally more robust and resistant to environmental factors. |

| Usage in Waterproof Applications | Polyethylene is commonly used in various waterproof applications, including: Packaging: Used for bags, films, and containers to keep products dry. Geomembranes: Used in landfill liners and pond liners due to its water impermeability. Clothing: Incorporated into waterproof jackets and outdoor gear. |

| Environmental Resistance | While polyethylene is waterproof, it may degrade over time when exposed to UV light and harsh environmental conditions. To mitigate this, UV stabilizers are often added to enhance its durability. |

| Sealing and Joints | For applications requiring seams or joints, additional sealing methods (such as heat welding or adhesive bonding) may be needed to ensure complete waterproofing. |

Overall, polyethylene is an excellent choice for waterproofing needs, with its effectiveness being enhanced by proper manufacturing and application techniques.

What does geomembrane liner do?

A geomembrane liner serves as a protective barrier that prevents the passage of fluids, gases, and contaminants. These liners are commonly used in a variety of environmental and engineering applications, such as:

| Landfill Liners | To contain waste and prevent leachate from contaminating groundwater. |

| Pond Linings | To retain water in artificial ponds, reservoirs, and canals. |

| Mining Operations | To prevent the escape of toxic chemicals used in mining processes. |

| Agricultural Applications | To line irrigation canals and waste lagoons. |

| Brine Evaporation Ponds | Geomembranes play a key role in the construction of brine evaporation ponds, serving as a barrier to prevent loss of the precious slurry. |

The primary function of a geomembrane liner is to provide a reliable, long-lasting barrier that ensures the containment of materials, protecting both the environment and human health.

Geomembranes are highly effective waterproofing solutions used in various industrial and environmental applications. Their ability to form an impermeable barrier is crucial for preventing the leakage of fluids and gases, making them indispensable in projects like landfill containment, pond lining, and chemical storage. Understanding the properties of materials like polyethylene and the methods for sealing geomembranes can help ensure their optimal performance and longevity in any application.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)