+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

Retaining walls play a crucial role in protecting landscapes from natural elements. Constructing the wall correctly with the proper materials ensures long-term stability. Cutting corners and not using a stabilizing grid can lead to wall failure, posing risks to people and damaging the landscape. When hiring professionals, always check their experience in this type of construction.

Common Reasons for Retaining Wall Failure

- Inadequate Drainage: Poor drainage behind the wall leads to moisture circulation, freezing, and thawing. This is a common issue in colder climates, especially during spring and fall. Clay backfill exacerbates this problem as it holds water, freezes, and expands, pushing the wall outward.

- Overloaded Walls: Retaining walls are sometimes forced to hold back more soil than they can handle. This is often due to inexperienced builders, but even seasoned landscapers can make this mistake.

- Height Issues: Without proper reinforcement, a retaining wall built too high cannot handle the force exerted on it. This can lead to expensive repairs or complete reconstruction.

Constructing a Good Retaining Wall

Building a retaining wall properly involves additional digging, backfilling, and compacting. Although this adds to the initial cost, it is far less expensive than rebuilding a failed wall. Unfortunately, many people are unaware of stabilizing grids and their necessity in construction. Hiring contractors who do not understand this can lead to costly mistakes.3

Using Stabilizing Grid

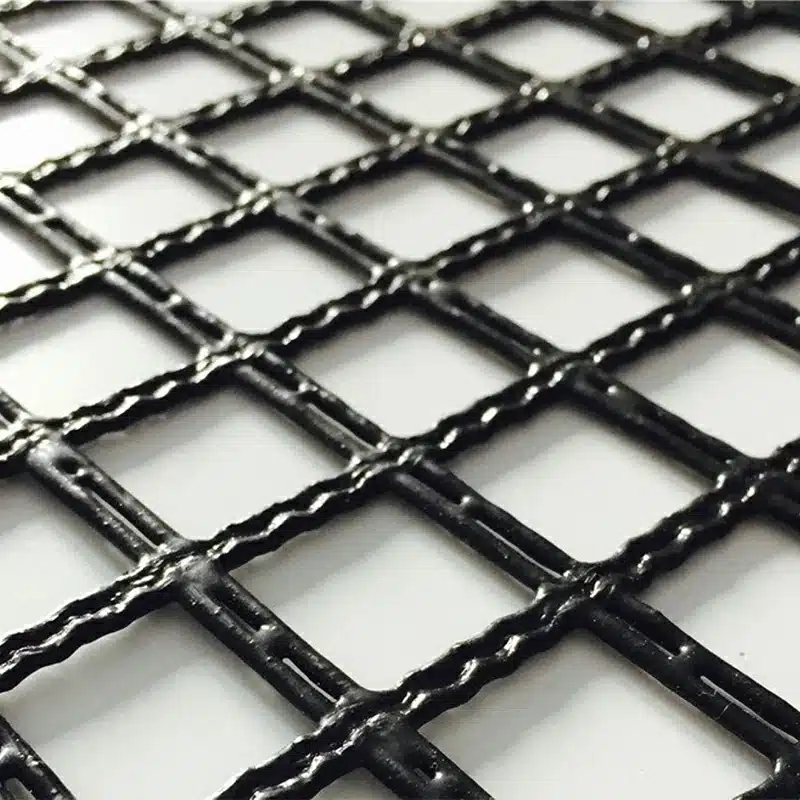

A retaining wall reinforcement grid (stabilizing grid) from SRW is a woven fabric with high tensile strength. It is pinned between the layers of the retaining wall, extending into the soil and locking the wall together with the soil behind.

When Is Stabilizing Grid Needed?

The need for a stabilizing grid depends on the wall material and the type of soil being retained. Clay soils, which swell and retain water, require stabilizing grids for effective retention. The material used for the wall also matters; more massive materials require less grid. For example, a stabilizing grid is recommended for split-face limestone walls over 24 inches in height. It is essential for man-made walls 36 to 48 inches high, especially if there is a slope at the base.

Steps to Build a Retaining Wall

- Step One: Excavation: Excavate the soil area for reinforcement. Remove all existing soils to maximize the embedment length for the stabilizing grid. Ensure a level soil condition behind the wall units for placing each grid layer.

- Step Two: Cutting the Stabilizing Grid: Cut the stabilizing landscape geogrid into sections from the roll to the specified length. Roll the grid from the wall toward the embankment, checking the manufacturer’s specifications for a biaxial or uniaxial grid. Generally, roll the grid perpendicular to the wall face.

- Step Three: Hooking the Grid: Hook the stabilizing grid over the Keystone pins to ensure a positive connection between the unit and the grid. Ensure the grid is placed within one inch of the wall’s face.

- Step Four: Securing the Grid: Pull the pinned stabilizing grid taut to eliminate loose folds. Secure or stake the back edge of the grid before and during backfilling and compaction. Remove the stakes after backfill if desired. Place additional grid sections abutting each other for continuous coverage.

- Step Five: Backfilling: Place backfill over the grid in 8-inch lifts. Ensure a minimum of 6 inches of reinforcement fill cover before driving any equipment over the grid. Avoid driving or turning vehicles directly over the grid to prevent damage.

Understanding Uniaxial Geogrid

Uniaxial geogrid is a lattice grid fabric made from high-strength composites or plastics like high-density polyethylene or polypropylene. It is used to reinforce paved roads and support retaining walls. Unlike geotextiles, which are non-woven or woven fabrics, uniaxial geogrids have a specific pattern that allows stress transfer along the longitudinal axis, making them suitable for various construction applications.

Where Is It Used?

Geogrid reinforcing fabric is used on steep walls, hillsides, retaining walls, and other vertical soil areas to prevent erosion and landslides. It also supports railroads and roads by reinforcing the earth beneath them, preventing damage and prolonging their lifespan.

Advantages of Using Geogrid Mesh

- Inexpensive compared to concrete retaining walls

- Reduce project time

- Makes land more usable by supporting steep hills

- Flexible design molds easily to uneven ground

- Earthquake-resistant, preventing soil loosening

- Allows grass to grow, maintaining a natural look

Different Geogrid Patterns and Manufacturing Methods

Patterns

- Uniaxial Geogrid: Stretched along the longitudinal direction, providing high strength in one direction.

- Biaxial Geogrid: Stretched in both longitudinal and transverse directions, offering equal strength in both axes.

- Triaxial Geogrid: A newer pattern stretched in all directions, resembling diamonds or triangles.

Manufacturing Methods

- Woven Geogrid: Made from tightly woven polyester with a polymer coating.

- Bonded Geogrid: Bonded at right angles using multiple sets of strands.

- Extruded Geogrid: Made of extruded polymers, providing a less flexible structure.

Final Thoughts

Geogrids are a simple yet elegant solution for stabilizing civil structures like retaining walls and paved roads. They reduce time and money investment while enhancing safety and structural integrity.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)