+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

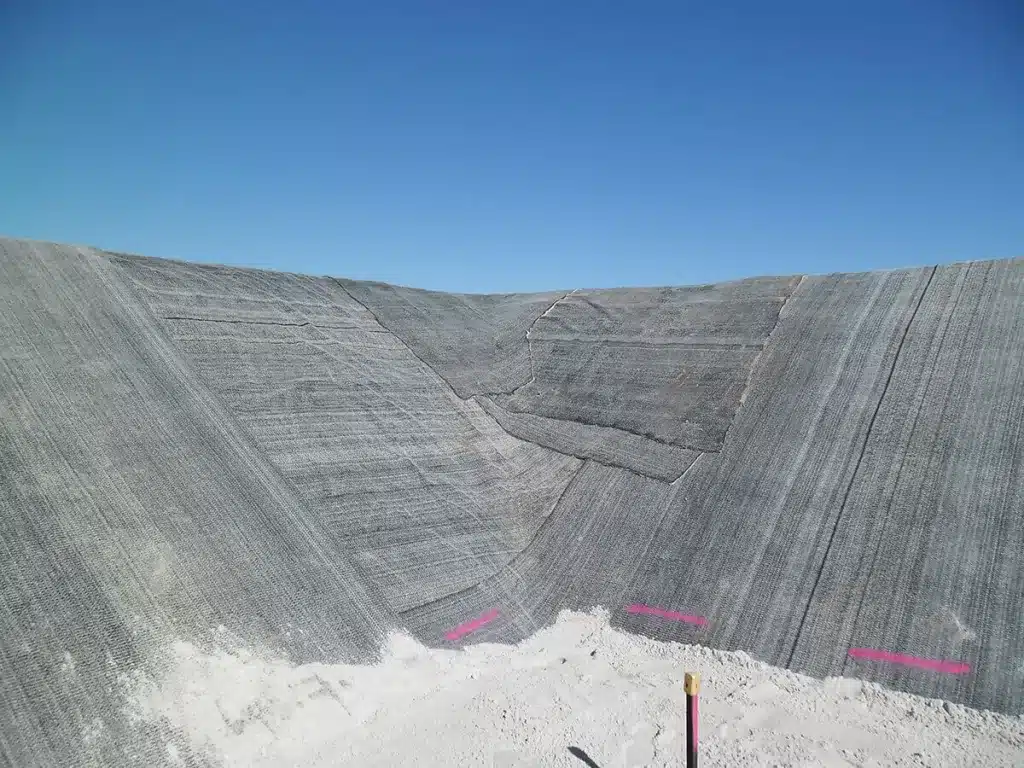

Geosynthetic clay liners, often referred to as GCLs, are an essential component in the realm of environmental engineering and containment systems. Understanding the properties of geosynthetic clay liners is paramount for their effective utilization in various applications. GCLs are engineered to combine the impermeable properties of natural clay with the reinforcing strength of geosynthetics, resulting in a versatile barrier material. These liners exhibit remarkable characteristics, including exceptional hydraulic conductivity, resistance to chemical degradation, and robust puncture resistance. They serve as vital components in landfills, ponds, and containment structures, where their unique properties provide an effective barrier against seepage and contamination.

What is a geosynthetic clay liner?

An assembled structure of geosynthetic materials and low-hydraulic-conductivity earth material (clay) in the form of a manufactured sheet to be used in civil-engineering applications, commonly known as a Geosynthetic Clay Liner or GCL, is a composite material specifically engineered for the containment and regulation of liquids or gases across a wide spectrum of uses. This engineered material comprises multiple layers of geotextiles that encapsulate a core layer composed of natural sodium bentonite clay. These individual layers are mechanically bonded together, creating a durable and exceptionally impermeable barrier.

What is the function of clay liner?

The primary function of a clay liner is to serve as a barrier to reduce porosity and decrease soil permeability, thus effectively preventing the migration of fluids. This includes averting the seepage of contaminants into the environment, safeguarding water resources, and stabilizing embankments, among other applications. Geosynthetic Clay Liners (GCLs) offer outstanding hydraulic performance, rendering them an ideal choice for advanced containment systems.

What are the properties of geosynthetic clay liners?

Geosynthetic clay liners exhibit several key properties:

- Impermeability: GCLs provide an exceptionally low hydraulic conductivity, preventing the passage of liquids or gases.

- Self-healing: When hydrated, the bentonite clay within the GCL swells, sealing small punctures and maintaining its impermeable properties.

- High Tensile Strength: The geotextile layers enhance the liner’s overall strength, ensuring it can withstand the stresses of various applications.

- Chemical Resistance: GCLs are resistant to a wide range of chemicals, making them suitable for applications involving hazardous substances.

- Environmental Compatibility: They are an environmentally friendly choice, as they utilize natural clay resources and reduce the need for synthetic materials.

What is the difference between geomembrane and geosynthetic clay liners?

While both geomembranes and GCLs are used for containment purposes, there are distinct differences. Geomembranes, which can have a smoother or textured surface, are synthetic, homogeneous sheets of plastic or rubber, offering consistent properties throughout. In contrast, GCLs consist of natural clay sandwiched between geotextiles, providing self-sealing abilities and increased puncture resistance. The choice between the two depends on the specific project requirements and the desired level of impermeability.

What are the geosynthetic clay liners made with?

GCLs typically consist of three main components:

- Bentonite Clay Core: This natural, sodium-based clay swells upon contact with water, forming a highly impermeable barrier.

- Geotextile Layers: These layers, typically made of woven or non-woven geosynthetic materials, provide reinforcement, strength, and protection to the clay core. Some GCLs include two needle-punched geotextile layers encapsulating a layer of sodium bentonite for enhanced performance.

- Needle-punching or Adhesive Bonding: To ensure structural integrity, the geotextile layers are mechanically bonded to the clay core.

In conclusion, geosynthetic clay liners are versatile, eco-friendly, and highly effective in various engineering and environmental applications. Their unique properties make them a valuable tool for containing and managing liquids and gases, promoting a safer and more sustainable future for construction and environmental projects.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)