+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

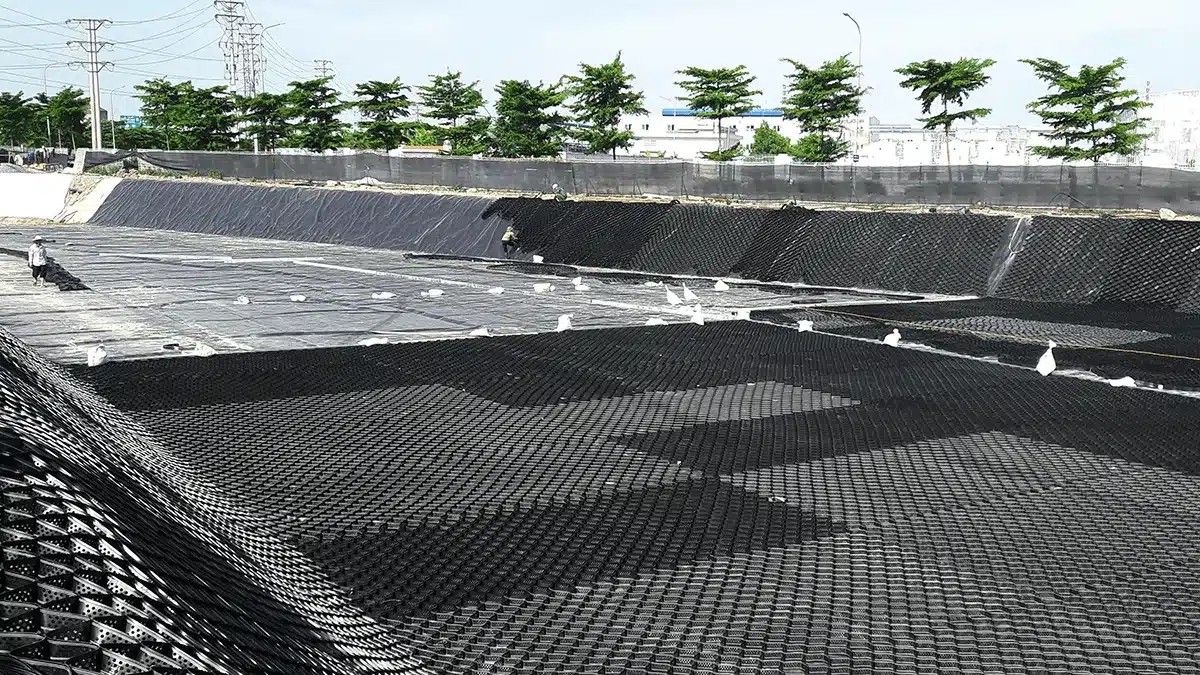

Geocells have revolutionized road construction, offering a cost-effective and sustainable solution to various road design challenges, particularly in geocell road design. In this article, we’ll delve into the world of geocells, explaining what they are, how they work, and their requirements, and answering common questions about their application in road construction.

What is Geocell in Road Construction?

Here’s a concise summary of Geocells in road construction:

- Limitations: Higher initial costs and need for proper installation.

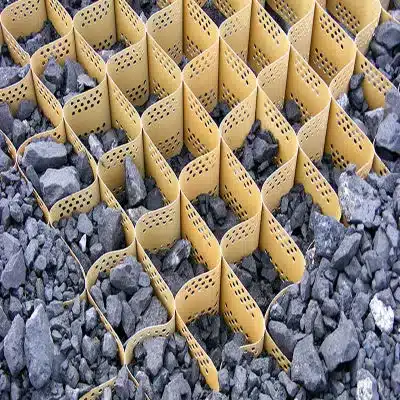

- What: Geocells are 3D polymer structures used for soil stabilization.

- Benefits: Enhance load distribution, improve drainage, and reduce road maintenance costs.

- Materials: Typically made of HDPE, filled with soil or gravel.

- Applications: Used in weak soil areas to reinforce road structures.

What are geotextiles generally used for?

Geotextiles are synthetic materials used in construction and environmental projects to improve soil stability, prevent erosion, and manage water flow. They are typically made from polymers and are used in applications like soil stabilization, drainage, and filtration. Geotextiles help strengthen foundations, protect against soil erosion, and allow water to pass through while filtering out soil particles. Types include woven, non-woven, and knitted fabrics, each suited for specific applications. In summary, geotextiles are vital for enhancing soil performance and ensuring sustainable environmental management.

Can geocell road design adapt to different soil conditions?

Yes, geocell road design can adapt to different soil conditions. It distributes loads evenly, increases shear strength, enhances drainage, and can be filled with materials like gravel or soil to suit various soil types. This flexibility makes geocells effective in both weak and strong soils.

What are the environmental benefits of geocell road design?

Geocell road design offers several environmental benefits that contribute to sustainable construction practices:

- Erosion Control: Geocells help stabilize the soil and reduce erosion by confining the fill material, which is especially beneficial in areas prone to heavy rains or on slopes.

- Reduced Material Use: The structure of geocells allows for the use of local or recycled materials within the cells, decreasing the need for quarried aggregates and reducing transportation emissions.

- Improved Drainage: Geocells can be designed to enhance water drainage through road bases, minimizing runoff and the potential for water pollution.

- Extended Road Life: By providing a more stable base, geocells extend the lifespan of roads, which reduces the frequency of repairs and the associated environmental impact of maintenance activities.

- Carbon Footprint Reduction: The overall reduction in material use, transport, and maintenance activities leads to a lower carbon footprint compared to traditional road construction methods.

These benefits make geocell technology a favorable option for environmentally conscious road construction projects.

In conclusion, geocell road design is a game-changer in the construction and maintenance of roads. Its ability to enhance load-bearing capacity, minimize environmental impact, and adapt to different soil conditions makes it a valuable asset for any road construction project. When properly installed and maintained, geocells can significantly extend the lifespan and durability of roads, providing long-term benefits for both infrastructure and the environment.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)