+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

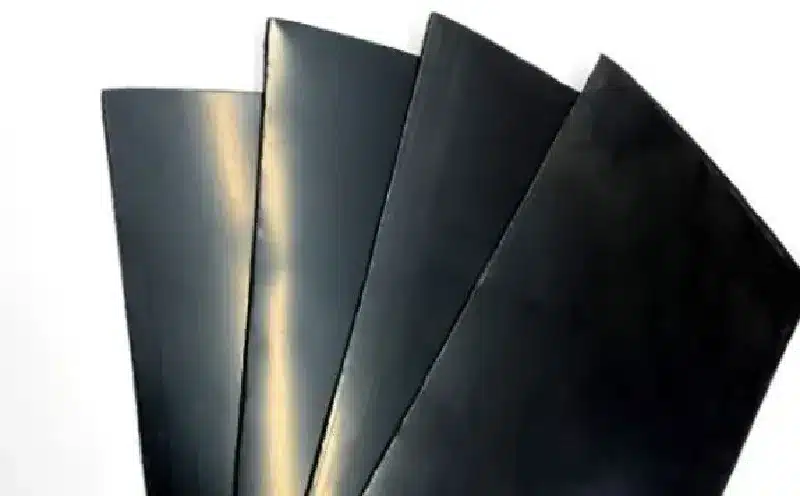

When it comes to geosynthetics, HDPE geomembrane plays a vital role in a variety of civil engineering and environmental projects. As a durable, flexible, and reliable material, HDPE geomembrane provides significant advantages in applications ranging from landfills to water containment. In this article, we’ll dive deeper into the uses and benefits of this essential material.

What is an HDPE geomembrane?

An HDPE geomembrane is a type of plastic sheet made from High-Density Polyethylene (HDPE) that is commonly used as a liner in various environmental applications. These geomembranes are durable, impermeable, and resistant to chemicals, UV radiation, and physical damage. They are widely used in applications like:

- Landfills – to prevent the leakage of hazardous liquids into the ground.

- Wastewater treatment – as liners in ponds, lagoons, or tanks to contain waste and prevent contamination.

- Mining – in heap leach pads and tailings ponds to prevent the escape of chemicals.

- Agriculture – as liners in irrigation and water storage systems.

HDPE geomembranes are favored for their strength, longevity, and resistance to punctures and tears, making them ideal for applications that require long-term containment or isolation of materials.

What are the main benefits of using HDPE geomembrane in construction projects?

HDPE (High-Density Polyethylene) geomembranes are widely used in construction projects for a variety of reasons. Some of the main benefits include:

- Excellent Chemical Resistance: HDPE geomembranes are highly resistant to a wide range of chemicals, including oils, acids, and solvents, making them ideal for projects like landfills, wastewater treatment, and chemical containment.

- Durability and Longevity: They have excellent UV and weathering resistance, ensuring a long service life even in harsh outdoor conditions. They can last for decades without significant degradation.

- Low Permeability: HDPE geomembranes provide very low permeability, making them effective at preventing water or liquid leakage, which is essential for applications like ponds, reservoirs, and containment basins.

- High Tensile Strength: HDPE geomembranes have high tensile strength, allowing them to withstand significant physical stress. This makes them suitable for applications where stability and reinforcement are important.

- Ease of Installation: They are lightweight, flexible, and relatively easy to handle and install, reducing labor costs and time on-site.

- Environmental Protection: HDPE geomembranes are used in environmental containment applications, such as protecting groundwater from contamination in landfills and waste containment areas.

- Cost-Effective: Despite their high performance, HDPE geomembranes are generally affordable compared to other materials with similar protective properties, making them a cost-effective solution for many projects.

- Adaptability: They can be customized for various thicknesses and sizes to suit specific project requirements, including flexibility for different terrains and contours.

In summary, HDPE geomembranes offer durability, chemical resistance, low permeability, and ease of installation, making them a reliable choice for environmental containment and other construction applications.

How is an HDPE geomembrane installed in construction projects?

- What is an HDPE Geomembrane: A high-density polyethylene (HDPE) sheet used as an impermeable barrier in environmental and construction projects, resistant to chemicals, UV radiation, and physical damage.

- Benefits of HDPE Geomembranes: High chemical resistance, durability and longevity, low permeability, high tensile strength, ease of installation, environmental protection, cost-effectiveness, and adaptability to different thicknesses and sizes.

- HDPE Geomembrane Installation: Involves surface preparation (leveling, compaction, and removal of sharp objects), proper delivery and storage, unrolling the sheets, panel placement and overlapping, and welding/seaming to ensure a long-lasting seal.

HDPE geomembranes are a versatile and reliable solution for containment in construction and environmental projects. Their chemical resistance, durability, low permeability, and ease of installation make them ideal for applications such as landfills, water reservoirs, mining, and agriculture, ensuring long-term protection and structural integrity.

In which industries is HDPE geomembrane commonly used?

HDPE geomembrane is used in a wide variety of industries where containment and environmental protection are key. Some common industries and applications include:

- Landfill Construction: Used as a liner to prevent leachate from contaminating the surrounding soil and groundwater.

- Water Management: Applied in reservoirs, ponds, and canals to prevent water loss due to seepage.

- Mining Industry: Used in heap leach pads and tailing ponds to contain hazardous materials and chemicals.

- Agriculture: Helps to line ponds for irrigation or maintain water tables in agricultural fields.

In summary, HDPE geomembrane is a versatile and reliable geosynthetic material with a range of applications. Its chemical resistance, durability, and cost-effectiveness make it an invaluable asset in various industries that require secure containment solutions.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)