Terram T1000 Non Woven Geotextile Membrane – Custom Size

Terram T1000 Non Woven Geotextile Membrane – Custom Size

- Brand GeoFanTex® GFE

- Product origin China

- Delivery time 7-14 days

- Supply capacity 40′ HQ/ 7 Days

Product Details

Polyester Nonwoven Geotextiles GeofanTex® GFE has main functional mechanical properties, permeable or impermeable properties, and soil-tightness. The datasheet as the blow is part of mechanical properties, not full of it. The permeable properties, loading quantities, or other details will be mailed to you if needed. As bellows.

(* Geofantex Geosynthetics can produce GeofanTex® GFE according to your requirement in constructions, MINIMUM ORDER QUANTITY: 20’ft Container)

Nonwoven Geotextile Fabric Specifications

| Properties (Standard) | Unit | GFE 100 | |

| Tensile Strength [ASTM D 4595] | T M | KN/m | 7.7 6.0 |

| Tensile Elongation [ASTM D 4595] | T M | % | 80 50 |

| Grab Strength [ASTM D 4632] | T M | N | 420 330 |

| Grab Elongation [ASTM D 4632] | T M | % | 80 50 |

| Weight | N/A |

|---|---|

| Dimensions | 10000 × 10000 × 4500 mm |

| Width | 0.5m, 1.5m, 2.25m, 3m, 4.5m, 0.3m – 6m |

| Length | 2m, 3m, 4m, 5m, 10m, 20m, 30m, 40m, 50m, 60m, 70m, 80m, 90m, 100m or according to your inquiry. |

| Brand | Geofantex GFE100 |

| Application | Civil Engineering, Commercial, DIY, Industrial, Residential, Self-Build |

| Brand | Geofantex GFE100 |

Non Woven Geotextile Fabric Advantages

Geofantex® GFE is 100% Polyester Continuous Filament Needle Punched non-woven Geotextile. Typically, this form of manufacturing offers superior hydraulic performance and high resistance to site installation stresses due to the nature of the continuous filament structure.

1. Nonwoven Geotextile Fabric For Separation

Use Polyester Continuous Filament Needle Punched non-woven Geotextile to separate building materials (such as soil and sand, soil and concrete) with different physical properties (particle size, distribution, consistency and density, etc.). Two or more materials are not lost or mixed, the overall structure and function of the materials are maintained, and the load-bearing capacity of the structure is strengthened.

2. Nonwoven Geotextile Fabric For Filtration

When water flows from the fine material soil layer into the coarse material soil layer, the good air permeability and water permeability of the Polyester Continuous Filament Needle Punched non-woven Geotextile are used to allow the water to pass through, and effectively carry the soil particles, fine sand, small stones, etc. Maintain the stability of water and soil engineering.

3. Nonwoven Geotextile Fabric For Drainage

Polyester Continuous Filament Needle Punched non-woven Geotextile has good water conductivity. It can form a drainage channel inside the soil and drain the excess liquid and gas from the soil structure.

4. Nonwoven Geotextile Fabric For Reinforcement

Use acupuncture geotextiles to enhance the tensile strength and deformation resistance of the soil, increase the stability of the building structure, and improve the soil quality.

5. Nonwoven Geotextile Fabric For Protection

When the water flow scours the soil, it effectively spreads, transmits or decomposes the concentrated stress, prevents the soil from being damaged by external forces, and protects the soil.

6. Nonwoven Geotextile Fabric Composite

Combined with the geomembrane, it becomes a composite waterproof and impermeable material, which plays a role of preventing puncture. High tensile strength, good permeability, air permeability, high-temperature resistance, freezing resistance, aging resistance, corrosion resistance, and no insects.

Applications of Non Woven Geotextile

(1) Used as reinforcement in backfilling of retaining walls, or used for anchoring panels of retaining walls. Build a wrapped retaining wall or abutment.

(2) Reinforce flexible pavement, repair cracks on the road, and prevent reflection cracks on the pavement.

(3) Increase the stability of gravel slopes and reinforced soil to prevent soil erosion and frost damage at low temperatures.

(4) The separation layer between the road ballast and the roadbed, or the separation layer between the roadbed and the soft foundation.

(5) The Separation layer between artificial fill, rock fill or material yard and the foundation, isolation between different frozen soil layers, filtering and reinforcement.

(6) The filtration layer of the initial upstream dam surface of the ash storage dam or tailing dam, and the filtration layer of the drainage system in the backfill of the retaining wall.

(7) The filtration layer around the drainage concealed pipe or the gravel drainage ditch.

(8) The filtration layer of water wells, relief wells or inclined pressure pipes in water conservancy projects.

(9) Geotextile separation layer between roads, airports, railway ballast and artificial rock fills and the foundation.

(10) Vertical or horizontal drainage inside the earth dam, buried in the soil, to dissipate the pore water pressure.

(11) Drainage behind the anti-seepage geomembrane in the earth dam or embankment or under the concrete protective surface.

(12) Eliminate the water seepage around the tunnel, reduce the external water pressure on the lining and the water seepage around the buildings.

(13) Drainage of artificially filled soil foundation, sports ground foundation.

(14) Highways (including temporary roads), railways, embankments, earth-rock dams, airports, sports fields and other projects are used to strengthen weak foundations.

Geofantex Geosynthetics have to make a series of guarantee for our products both plant processing and selling out to our customers. The selling to you is the first step, the service, and guarantee is our task. Geofantex Geosynthetics have an ISO Certificate to guarantee the raw material, the product processing, and the end product. From receiving your order to replacement and installation of the products, we have solved the problems in time if you need, whatever the quality and technics guideline or suggestions. Our company has been committed to supplying high-quality products with reasonable price and delivery in time.

MANUFACTURING QUALITY ASSURANCE

GEOFANTEX has an on-site Manufacturing Quality Assurance Laboratory at factory. GEOFANTEX maintain a high level of quality and up-to-the-minute results on finished products through a fully equipped, well staffed, dedicated laboratory existing in each of the manufacturing facilities. Each facility follows the same guidelines for evaluating the quality of GEOFANTEX products and is capable of adapting to market-driven requirements.

A. Objective

The objective of the GEOFANTEX Quality Assurance program is to define implementation of basic manufacturing quality assurance (MQA) procedures necessary to ensure consistent production of quality products supplied to the geosynthetic market. Note that at this time, these procedures are limited to Polyester (PET) Continuous Filament Nonwoven Geotextile

B. Scope

In order to achieve GEOFANTEX’s stated purpose, a rigorous set of minimum standards and an effective test program to assure compliance has been established. These procedures and requirements are frequently reviewed and adjusted to assure compliance with current market demands and/or predetermined project specifications. These procedures assure that raw materials and process parameters are controlled to provide products complying with GEOFANTEX’s pre-defined minimum characteristics.

PRODUCT IDENTIFICATION AND DOCUMENTATION

A. Roll Numbering

Each roll of geotextile is assigned a unique roll number. The Quality Assurance Laboratory maintains records documenting the raw materials and resulting product quality information.

B. Approval Procedure

Results for each tested roll of product are checked against both GEOFANTEX China standard and customer specifications for compliance. The Quality Assurance Laboratory approves those materials that meet these requirements for shipment.

C. Non-Conformance

Material that does not meet GEOFANTEX minimum standards is given a roll number, but is rejected and not placed into inventory. The material is identified as scrap and will not be utilized. Material that meets GEOFANTEX minimum standards but does not meet a stricter customer specification is not allocated to that customer, but is placed into inventory as GEOFANTEX standard material.

D. Documentation

Individual Quality Assurance Certificates are generated and supplied for each roll of needle punched nonwoven geotextile product to include all relevant quality assurance information about the material(s).

Geofantex Geosynthetics have a series of package and delivery service working procedures. Geofantex Geosynthetics have supply thousands of containers to Latin America, North America, Southeast Asia and developed countries and Africa within the past ten years. We provide the package of products with the rolls, pots, bags, sheets, or your requirement in orders. Our company has been committed to supplying high-quality products with reasonable price and delivery in time. Delivery one 40’HQ within 7 – 10 days. And we have an obligation in increasing loading quantity and make you save the freight costs maximally. We supply the products by plane, by sea and land carriage to any regions or any countries of the worldwide, even the door-to-door service.

| SEPARATION | REINFORCEMENT | FILTRATION | DRAINAGE | WATERPROOF | PREVENTION | POLLUTION PREVENTION | PROTECTION | CONSOLIDATE | |

| GEOTEXTILE | √ | √ | √ | √ | √ | √ | |||

| GEOMEMBRANE | √ | √ | √ | ||||||

| GEOGRID | √ | √ | |||||||

| GEONET | √ | ||||||||

| GEOTUBE | √ | ||||||||

| GEOCELL | √ | √ | |||||||

| GCL | √ | √ | |||||||

| GEOCOMPOSITE | √ | √ | √ | √ | √ | √ | √ |

What is Polyester (PET) Continuous Filament Nonwoven Geotextile (GeofanTex® GFE)

Polyester (PET) Continuous Filament geotextile is polyester filament needle-punched non-woven geotextile fabric. It does not contain chemical additives and does not undergo heat treatment. It is an environmentally friendly building material. Furthermore, it can replace traditional engineering materials and construction methods, making construction safer, and has contributed to environmental protection, it can solve the basic problems in project construction more economically, effectively and lastingly.

PET (Polyester) Long Fiber Nonwoven Geotextile (GeoFanTex ® GFE) is 100% Polyester Continuous Filament Needle Punched non-woven Geotextile, with maximum 6m-width. These synthetic fibers are made into flexible, porous fabrics by standard weaving machinery or are knitted in a random nonwoven manner. The major point is that PET(Polyester) Long Fiber Nonwoven geotextiles are porous to liquid flow across their manufactured plane and also within their thickness, but to a widely varying degree. PET Long Fiber Nonwoven Geotextile (GeoFanTex ® GFE) have a very high melting point and UV resistance and have many applications in filtration and separation, protection and drainage.

Polyester long fiber non-woven geotextile has an excellent heat resistance and light resistance. Even if it is exposed to a short-term environment of nearly 20 ℃, its performance has almost not change. After a large number of tests and practices, the polyester long fiber non-woven geotextile has long-term corrosion resistance to various natural soils, moisture, and microorganisms.

The package of nonwoven geotextile is PE, the color of the package is black, the MOQ (minimum order quantity)of white of is 20’GP, the one of grey is 40’HQ, the PET(Polyester) Long Fiber Nonwoven Geotextile (GeoFanTex ® GFE) could be made into a bag, pot, roll or according to customers’ requirements.

Development history of the Geofantex

2014 — Geofantex Geosynthetics Co., Ltd. Factory was established

2015 — promoting the new image and building GeoFanTex brand

2018 –Geofantex products exceeded 100 million dollar

2019 — Upgrade new nonwoven geotextile, Geomembrane, and Composite geomembrane production line.

2020 — The new factory was completed.

2021 — Upgraded production line of the factory, making all the products could meet ASTM, AS, and ISO standards.

2022— Improve the quality of after-sales service and launch customized products.

Company Profile

Geofantex Geosynthetics Co., Ltd. is located in the beautiful coastal city of Dalian, with superior geographical location, convenient transportation, and developed communications. The company was founded in 2014 with a registered capital of 5,000,000 yuan. It has an industrial park covering an area of more than 50 acres in Jinan, Shandong. It has a modern office environment, advanced production equipment, and a group of high-quality and professional technical and management personnel.

The company gives full play to its own innovation advantages, platform advantages, and market advantages, and with the support of national policies, builds a national first-class enterprise, always follows the principle of “quality first, reputation first”, adhering to the principle of “people-oriented, quality for survival, integrity, unity and hard work”, Integrated enterprise spirit, sincere cooperation with various engineering units and colleagues from all walks of life, harmonious development, and work together to make greater contributions to infrastructure.

Frequently Asked Questions

Buy Terram T1000 Non Woven Geotextile Membrane In Custom Sizes

We now sell custom sized geotextiles in two brands, they both do exactly the same job and are designed for the same purpose.

To make life easier for our customers EasyMerchant is offering this Terram T1000 Membrane in custom sizes. This offers the easiest and cheapest way to buy Terram standard geotextiles anywhere. We roll out the full roll and cut off the size you require, saving you money and saving waste! Please do bear in mind that as this is a cut roll, that we have to unroll it in the yard and then fold it back up again once cut. It may arrive to you wet, or with some markings or dirt on it. I presume this won’t be an issue as it is to be buried underground, but I just want to make sure our customers are aware so that there are no surprises!

Generally custom sizes will come folded, 100m lengths will come on a roll. Occasionally small cuts will come on a roll too, but only if it’s the last remaining piece of the roll.

Terram geosynthetics are a manufacturer of Geotextile Membrane products. Their most commonly sold product is this one, the Terram T1000.

Terram membrane is used as a trench liner for French drains as well as for wrapping soakaway crates or for use under patios and paths. Terram membrane is a geotextile membrane with industry leading hydraulic and technical properties to deal with all requirements of ground stabilisation, ground protection and filtration and separation. The Terram membrane is used to protect against the loss of building aggregates into a soakaway system.

Typical uses for Terram standard geotextiles include floor stabilisation, ground protection and maintaining separation of granular layers.

Used in the building of:

- Paved and unpaved roads

- Railways

- Car parks and hardstandings

- Cycleways and footpaths

- SuDS installations

- Green roofs

- Ground stabilisation

- Ground Protection

Benefits:

- Proven separator functionality

- Outstanding filtration capacities

- Acceptable for soakaway crate systems

- Separates granular layers

FAQ

What is Terram?

Terram T1000 is a non woven geotextile membrane used to separate aggregates while allowing water to drain through it. Terram is the brand name of the manufacturer.

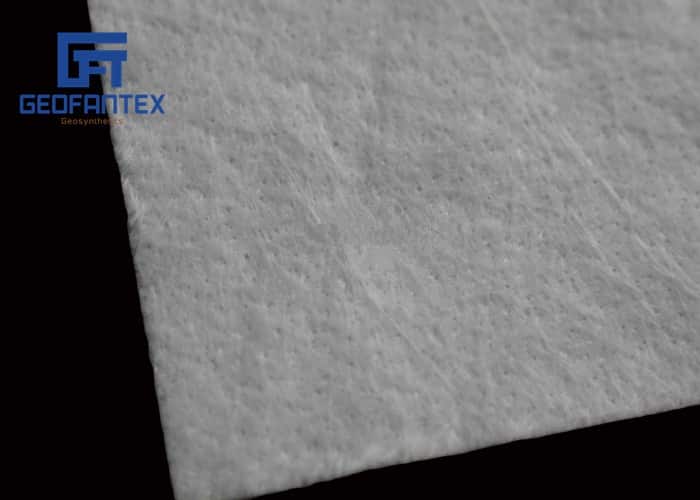

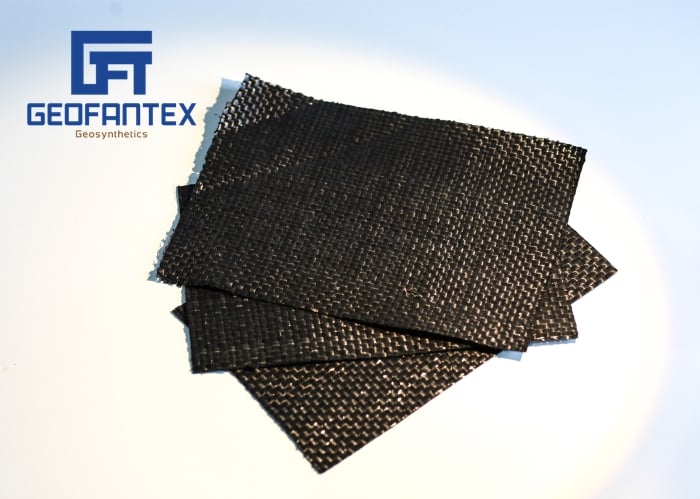

What is the difference between black and white membranes?

The black membrane is a woven product which does not allow water to drain through it. The white fabric is non woven and will allow water to drain through it.

What are typical uses for this product?

Typical uses would include:

– Underneath block paved driveways – Pebbled driveways – Wrapping soakaway crates for a soakaway system – Road and pavement construction – Rainwater harvesting and attenuation – Preventing rootzone soil from being washed into the sub base stone – With paving grids to prevent the gravel intermixing with the larger sub-base layers – Separating aggregate layers in car parks and overflow car parks – Underneath permeable paving surfaces – Underneath children’s play areas – Sand pits and safety mulch – As a French drain and with land drainage systems – On green roofs – As a pond liner underlay to fit beneath the pond liner

Will this work as a pond liner underlay?

Yes this membrane is perfect for use as a pond liner underlay. If the ground conditions are sharp you may require the 200gsm or 300gsm versions instead however.

What is the difference between Terram T1000 and Lotrak 100?

Not a lot! They’re both white non woven membranes designed for all the same uses. They’re just made by two different manufacturers. Both are made in the UK, they both do exactly the same job and are designed for the same purpose.

What thickness do I need?

The products sold on this page are 100GSM, which is the most popularly sold thickness. We do also keep 200GSM and 300GSM in stock. So if you think you need a different thickness then get in touch!

What is the difference between Woven and Non Woven?

The woven membrane is black in colour and does not allow water to drain through it, the white non woven membrane allows water to drain through it.

Is this a weed barrier?

Though this membrane will no doubt help to stop weed growth, it is not rated as a weed barrier.

| Specifications: | |

| Brand: | Terram, GEOFANTEX GFP |

| Material: | Polyethylene |

| Product: | Terram T1000 Non-Woven Geotextile |

| Weight (GSM): | 100 |

| Tested to: | BS EN ISO 9001 |

| Pore Size 90% Finer than (microns): | 90µm |

| Tensile Strength: | 8 |

| Tensile Elongation: | 60 |

| Elongation at Max Load MD (%); | 22 |

| Elongation at Max Load CD (%): | 15 |

| CBR Puncture Resistance (N): | 1500 |

| Cone Drop Penetration (mm): | 38 |

| Water Permeability (H50): | 90 |

| Effect of UV Light: | UV Inhibited |

| Full Roll Size: | 4.5 x 100m |

| CE Marked? | Yes |

| Gross Roll Weight: | 54kg |

| Specifications: | |

| Brand: | Geofantex |

| Material: | Polyethylene |

| Product: | GFP 100 Non-Woven Geotextile |

| Tested to: | BS EN ISO 9001 |

| Pore Size 90% Finer than (microns): | 100 |

| Tensile Strength (kN/m) MD: | 8 |

| Tensile Strength (kN/m) CD: | 8 |

| Elongation at Max Load MD (%): | 45 |

| Elongation at Max Load CD (%): | 45 |

| CBR Puncture Resistance (N): | 1500 |

| Cone Drop Penetration (mm): | 36 |

| Water Permeability (x 10-3) (m/ sec) 11058 | 130 |

| Effect of UV Light: | UV Inhibited |

| Full Roll Size: | 4.5 x 100m |