+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

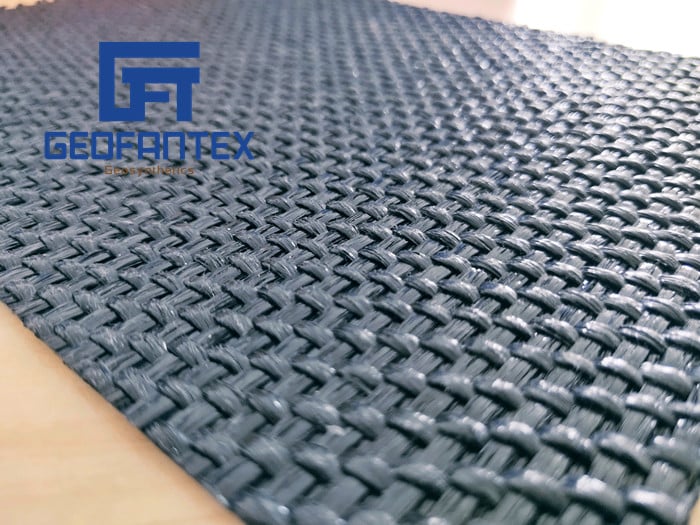

The installation and construction of geotextiles require strict adherence to guidelines to ensure the longevity, performance, and effectiveness of the geosynthetic material. Here’s a comprehensive, strict method to follow for geotextile installation in any application:

Pre-Installation Preparation

Pre-installation preparation is a critical step to ensure a smooth and efficient installation process. It involves a thorough site assessment to verify space, environmental conditions, and potential hazards. Technical requirements must be reviewed, including compatibility with the existing infrastructure and compliance with local codes and standards. All necessary tools, equipment, and safety gear should be prepared in advance. Reviewing documentation such as installation manuals and technical datasheets is essential, along with confirming that all components have been delivered and are in good condition. Properly trained personnel should be assigned, and the installation schedule coordinated to avoid conflicts. Finally, the installation environment must be clean, well-lit, and ready to support a safe and successful setup.

- Alignment: Lay the geotextile material parallel to the slope or in the direction of the intended flow of water, as required by the design. Geotextiles must be aligned correctly to function as intended.

- Unrolling: Unroll the geotextile along the prepared subgrade without stretching it. Ensure that no tension is applied during the unrolling process.

- Overlap: When placing geotextile sheets or rolls, ensure proper overlaps. The minimum overlap should be at least 300 mm (12 inches) but may vary depending on project requirements.

- Seam Connection: For larger areas, geotextiles are often joined by heat-sealing, stitching, or other approved methods. The seams should be securely bonded to prevent separation.

- Avoid Wrinkles: Geotextiles should be laid flat with minimal wrinkles or folds. If wrinkles occur, they should be smoothed out, ensuring the material maintains good contact with the subgrade.

Securing the Geotextile

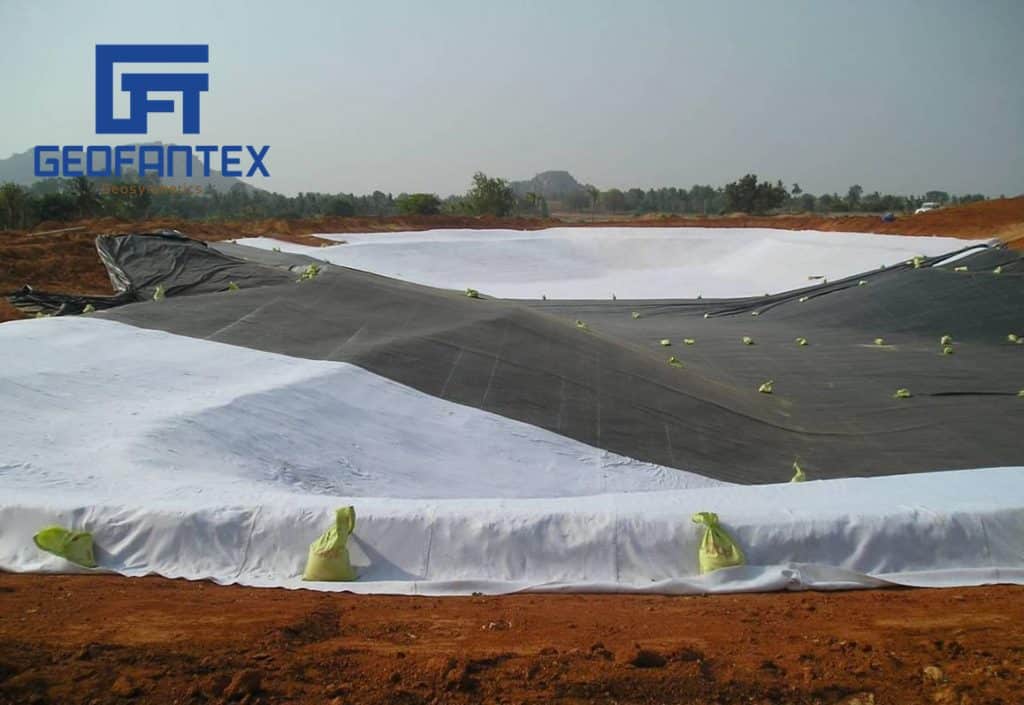

- Anchoring: Secure the edges and overlaps of the geotextile using stakes, pins, or weights to prevent it from shifting during installation.

- Use of Sandbags or Temporary Weights: For wind protection or if installation occurs in windy conditions, temporary weights like sandbags can be used to hold the geotextile in place until permanent construction begins.

Backfilling or Covering

- Covering Layer: After installation, the geotextile should be immediately covered with the intended backfill material, such as soil, aggregate, or gravel. This step is crucial for protecting the material from UV degradation and mechanical damage.

- Controlled Backfilling: Backfill material should be placed carefully over the geotextile to avoid damage during compaction. The compaction process should be done in layers, avoiding excessive compaction directly on the geotextile.

- Compaction: If required by the project, backfill should be compacted according to the project specifications. Excessive compaction should be avoided to minimize stress on the geotextile.

Quality Control and Inspection

- Post-Installation Inspection: Regularly inspect the geotextile for any tears, wrinkles, or improperly aligned sections. Ensure that all seams are intact and overlaps are correctly placed.

- Conformance with Design Specifications: Verify that the material and installation process meet the specifications outlined in the project design, including strength, permeability, and thickness.

- Testing: If required, perform tests on the geotextile to verify its properties, including tensile strength, elongation, and permeability.

Safety and Environmental Considerations

- Safety Measures: Ensure that all workers are aware of the handling, storage, and installation procedures to minimize risks. Use appropriate protective gear when handling geotextile rolls.

- Environmental Protection: Avoid exposing geotextile materials to harsh weather conditions, UV light, or excessive moisture. Install it promptly after unrolling to minimize exposure time.

Maintenance and Monitoring

- Inspection After Installation: Periodically inspect the installation to ensure the geotextile is performing as expected. Check for signs of wear or damage, particularly at seams, overlaps, and edges.

- Post-Construction Monitoring: Continue to monitor the geotextile during the operational phase to ensure that it remains intact and functional.

This method ensures the proper performance of geotextiles and guarantees their effectiveness in reinforcing, draining, or separating materials as per the design criteria. Each step is critical to prevent any long-term issues that may arise from improper installation.

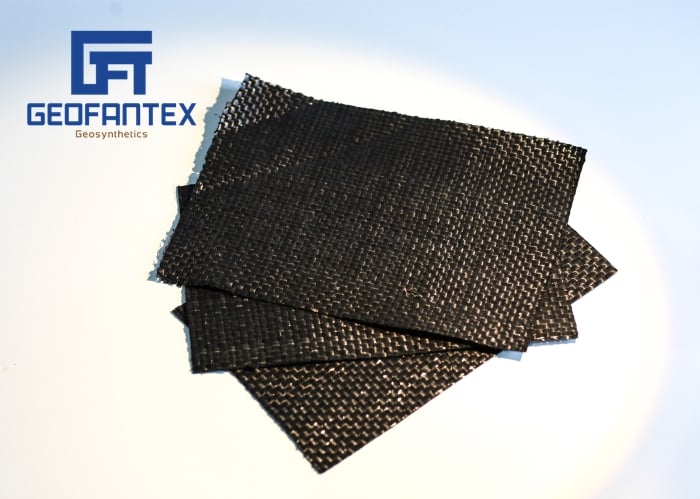

Get Free Sample

We’ll respond as soon as possible(within 12 hours)