+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

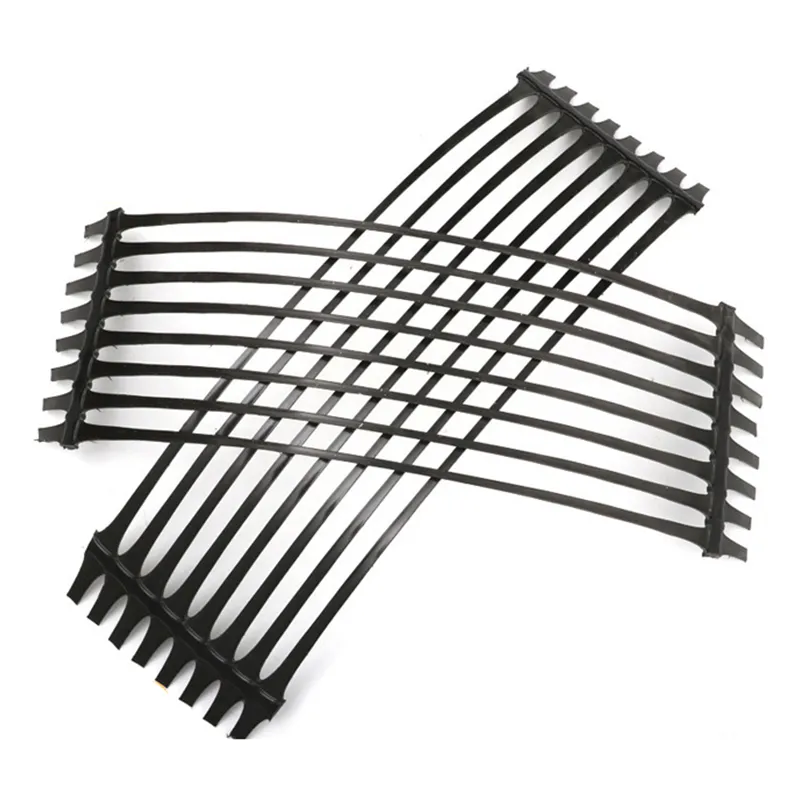

Uniaxial geogrids are specialized materials commonly used in civil engineering and construction. They have a grid-like structure with parallel ribs, reinforcing in one direction. This makes them stronger along their length. Uniaxial geogrids are primarily used to enhance stability and strength in soil and aggregates, in applications such as soil stabilization, slope reinforcement, retaining wall construction, and road and railway projects.

How do uniaxial geogrids differ from other geosynthetic materials?

Uniaxial geogrids have a unique grid-like design with parallel ribs, providing reinforcement in a single direction, which sets them apart from other geosynthetic materials like geotextiles or biaxial geogrids.

What are the advantages of using uniaxial geogrids in soil stabilization?

Uniaxial geogrids reinforce the soil behind retaining walls by extending horizontally into the retained soil. This creates a stable mass that can withstand lateral earth pressure, preventing soil movement and maintaining the integrity of the retaining wall.

How do uniaxial geogrids help in retaining wall construction?

One of the most common and effective drainage systems is the French drain. This is a subsurface drainage system and can be effective in spreading and diverting pooling problems.

What factors should be considered when using uniaxial geogrids in road construction?

When using uniaxial geogrids in road construction, important considerations include traffic load, subgrade conditions, and climate. Geogrids should be selected based on their strength and durability to withstand expected loads and environmental conditions. Proper installation techniques and connection details should also be followed to ensure effective reinforcement and long-term performance.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)