+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

In the realm of civil engineering and infrastructure development, every layer counts. Among the crucial components ensuring the stability and longevity of structures lies geo filter fabric, a remarkable innovation. This article delves into the essence of the geo-fil fabric, its types, and filter criteria, and sheds light on the distinctions between filter fabric and geotextile fabric.

What is geotextile filter fabric?

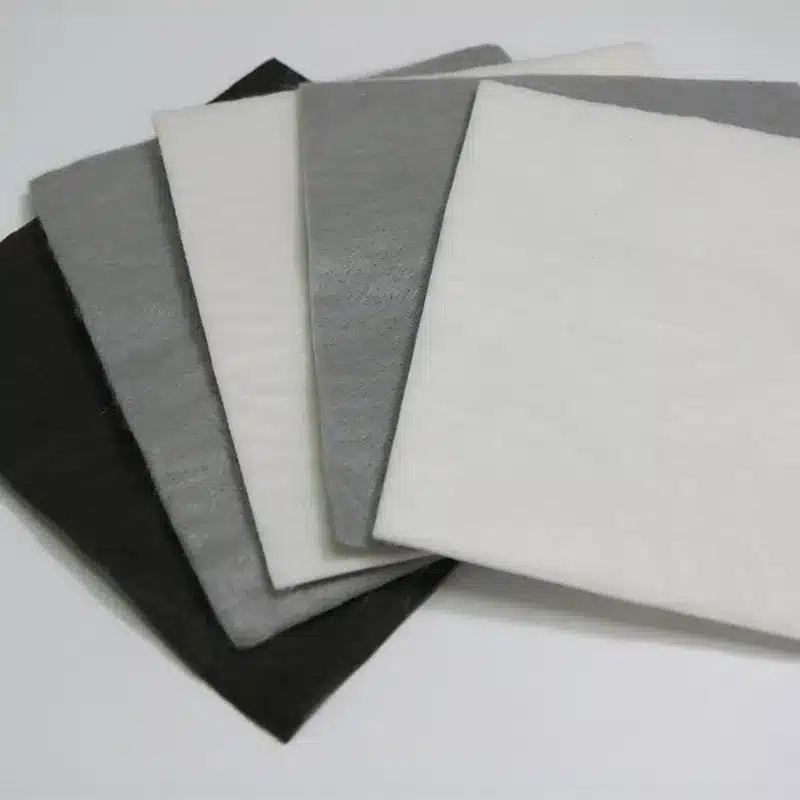

Geotextile filter fabric, often simply referred to as geo filter fabric, is a synthetic material designed to perform a multitude of functions in civil engineering projects. Its primary purpose is filtration, separating fine particles from fluids such as water or gases while allowing the passage of fluids. These fabrics are essentially permeable, and capable of filtering, separating, reinforcing, draining, or protecting the soil, depending on the specific needs of the project.

What are the three types of geotextile fabric?

- Woven Geotextiles: Made by weaving individual yarns together, woven geotextiles offer high tensile strength and stability, suitable for applications requiring robust reinforcement. These fabrics are available in various forms, such as non-woven geotextiles, woven geotextiles (needle punched), or heat-bonded geotextiles (structural woven), each tailored to specific engineering requirements.

- Non-Woven Geotextiles: Comprising fibers bonded together through mechanical, thermal, or chemical processes, non-woven geotextiles excel in filtration and drainage tasks due to their porous structure. These fabrics are a vital component in civil engineering projects, alongside woven geotextiles (needle punched) or heat-bonded geotextiles (structural woven), offering versatility and reliability in various applications.

- Knitted Geotextiles: Utilizing knitting techniques, these geotextiles provide flexibility and stretch, ideal for applications demanding conformity to irregular surfaces. These fabrics, along with woven geotextiles (needle punched) or heat-bonded geotextiles (structural woven), contribute to the resilience and durability of infrastructure projects, ensuring optimal performance in diverse environmental conditions.

What are the filter criteria for geotextile?

The effectiveness of geotextiles in filtration depends on several criteria:

- Permeability: The ability to allow fluids to pass through while retaining particles. This crucial aspect is influenced by the fabric’s pore size distribution. Notably, in high-quality geotextiles, 90% of the pores within the fabric are smaller than the O90 value, ensuring efficient filtration while maintaining optimal flow rates.

- Durability: Resistance to physical, chemical, and biological degradation over time. Geotextiles must withstand environmental stresses, such as UV exposure, soil chemicals, and microbial activity, to maintain their filtration efficiency and structural integrity throughout their intended lifespan.

- Opening Size: The size of the pores or openings within the fabric, determining the particles’ retention capacity. By controlling the distribution of pore sizes, geotextiles can effectively trap sediment particles while allowing water or gases to pass through, mitigating soil erosion and enhancing drainage systems.

- Hydraulic Gradient: The rate of change of fluid pressure with respect to distance along the flow path, influencing the flow dynamics through the fabric. Geotextiles with optimized hydraulic properties facilitate efficient water flow, reducing the risk of clogging and ensuring sustained filtration performance in diverse environmental conditions.

What is the difference between filter fabric and geotextile fabric?

The effectiveness of geotextiles in filtration depends on several criteria:

While filter fabric and geotextile fabric share similarities in function, they differ in composition and application. “Filter fabric” is a generic term used to describe geotextiles whose primary function is allowing water to pass while keeping soil fines from migrating through the fabric. Typically made of woven monofilament materials, filter fabric focuses primarily on filtration and is often used in drainage systems to prevent soil erosion and retain fine particles. On the other hand, geotextile fabric encompasses a broader spectrum of functions beyond filtration, including reinforcement, separation, and drainage, and can be woven, non-woven, or knitted depending on the specific requirements of the project.

Geo filter fabric stands as a cornerstone in modern infrastructure development, offering versatile solutions to enhance stability and resilience. Understanding its types, filtration criteria, and distinctions from traditional filter fabric illuminates its pivotal role in safeguarding structures against environmental forces. As civil engineering continues to advance, the significance of geo-filter fabric only grows, fortifying the foundation of tomorrow’s world.

Get Free Sample

We’ll respond as soon as possible(within 12 hours)